Quarry & Workshop Equipment

(Also see: the Stone Carver “Tools & Equipment,” “From Quarry to Cemetery Monuments – Tools & Equipment Used in the Stone Shops & Mills (saws, hand tools, etc.),” and “Quarrying Methods” sections of our web site.)

Seeking information about the quarry drag saw in the photographs below.

Lynn Northrop and her husband, and Wayne Northrop are seeking information on the quarry drag saw in the photographs below. (Lynn and Wayne Northrop own and operate the Raymond Museum located at Raymond, Madera County, California. You can read more about the Raymond Museum on the online article, “Raymond Museum now an historical place of interest,” by Elizabeth Gabriel, May 30, 2008, on the Sierra Star web site.)

The stone saw shown in the photographs below was donated by Mark Ward, owner of Mark Ward Truckin; and it was recently moved and installed by local volunteers as a new exhibit at the Raymond Museum (August 2010).

If you have any knowledge of this saw, please contact Lynn and Wayne Northrop at the Raymond Museum. Below is Lynn’s brief history of the saw:

“It was possibly a marble cutting saw moved from San Francisco in the 1890s or early 1900s. It sat at a small quarry near Bates Station, an old Stagecoach stop near the Madera Quarry about 12 miles from Raymond. A man named Carl Taylor ran it in the 1930s and then walked away with the blade still stuck in a slab of granite. The iron cutting blades run vertically instead of horizontally and the screw system is still intact on top lowering the blades as the water and shot cut through the slabs. We are trying to date the saw style and find out where it may have come from and if there are others left around California or the country (USA).”

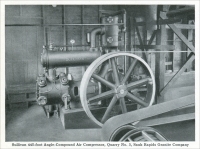

- Air Compressor (circa 1925) from The Story of the Rock of Ages, Boutwell, Milne & Varnum Company, Montpelier, Vermont, written and compiled by Athol R. Bell, 1925.

- Air Compressor (circa 1926) – Sullivan Portable electric air compressor, from Stone, Vol. XLVII, No. 11, November 1926, pp. 684.

- "Air Power Economy in a Granite Quarry," from Mine and Quarry Magazine, Vol. III. No. 1, June 1908, Sullivan Machinery Co., Publisher, Chicago, Illinois. (The Rockport Granite Company of Rockport, Massachusetts, is discussed.)

- An Electrically-Operated Tool for Dressing and Carving Stone, etc. (April 1893) The Manufacturer and Builder, Vol. 25, Issue 4, April 1893, pg. 87. (Article in digital images viewed at American Memory, Library of Congress.)

- An English Stone-Working Machine (September 1891) The Manufacturer and Builder, Vol. 23, Issue 9, September 1891, pg. 207. (The article includes a sketch of this machine.) (Article in digital images viewed at American Memory, Library of Congress.)

- Application of the Electric Light at the Angers (France) Slate Quarries (January 1885) The Manufacturer and Builder, Vol. 17, Issue 1, January 1885, pgs. 12-13. (Article in digital images viewed at American Memory, Library of Congress.)

- Block Making Machine (YouTube video) McGirren Engineering

- Bridge Milling Machine (YouTube Video)

- Brunner & Lay: Manufacturers of Marble, Stone, Granite and Bricklayers' Tools, Stone Jacks, Derricks, and Contractors' Supplies (Catalog). Chicago, Illinois. (You can also use this Brunner and Lay Tool Catalog PDF link to view the booklet in PDF format.)

- Burr Stones (April 1876) The Manufacturer and Builder, Vol. 8, Issue 4, April 1876, pgs. 82-83. (Article in digital images viewed at American Memory, Library of Congress.)

- "Carl Meyer Celebrates 100th Anniversary with First Diamond Gang Saw for Granite," Dimensional Stone, Vol. 6, No. 8, Anon., pp. 56-58, 1990b.

- Carving Stone by Electricity (February 1893) The Manufacturer and Builder, Vol. 25, Issue 2, February 1893, pg. 39. (Text of article in digital images viewed at American Memory, Library of Congress.)

- Channeling Machine (circa March 1873) – “Improved Stone Quarrying Machine,” in Scientific American, Vol. XXVIII, No. 13, March 29, 1873, pp. 191.

-

Channeling Machines – “Channeling Rock Walls for Foundations,” by William M. McKearin & “Device For Drilling in Trenches,” in Mine and Quarry, Vol. VII, No. 1, October 1912.

- Channeler – “The Marble Industry in New York State,” in Mine and Quarry, February 1907. (History and photographs of the South Dover Marble Company located at Wingdale, New York)

- Channeler – Photograph of channeler in use in a sandstone quarry near Tenino, Washington in “Tenino, Washington,” by Miss Blendine Hays, “Tenino, Washington,” The Coast: Alaska and Greater Northwest, Vol. 17, No. 3, March 1909, pp. 199-204, The Coast Publishing Co., Seattle, U.S.A.

- Channeler – Sullivan Machine Company Duplex Channeler – “Marble Quarrying in Arizona,” in Mine and Quarry Magazine, Sullivan Machinery Co., Chicago, Vol. V., No. 2, October 1910, pp. 440-443.

(photo caption) “Sullivan duplex channeler at Arizona Marble quarry.” (pp. 442) - Channeling Machine (Electric) (circa 1926) in “The Romance of Verde Antique,” by Basil B. Walsh, in The Vermonter, Vol. 31, No. 9, 1926, pp. 130-136.

- “Channeling ‘Pressure’ Stone,” article from Mine and Quarry, Sullivan Machine Company, Chicago, Illinois, Vol. VI, No. 3, March 1912, pp. 583-584.

-

Channeler – “A New Sullivan Diamond Drill,” Mine and Quarry, Sullivan Machinery Company, Chicago, Illinois, Vol. VII, No. 2, April 1913, pp. 724-725.

- Chisel & Hammer used in the Penrhyn Slate Quarries in North Wales circa 1858 – from The Penrhyn Slate Quarries in North Wales circa 1858, in The Illustrated London News, April 17, 1858, pp. 392-393.

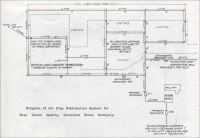

- Compressed Air Power Transmission Plant – “A Modern Compressed Air Power Transmission Plant” (at the Cleveland Stone Company’s Gray Canon Sandstone Quarry located near North Amherst, Ohio), in The Engineering Record, Vol. 50, No. 2, July 9, 1904.

- The Concord Stone-Polishing Machine (August 1890) The Manufacture and Builder, Vol. 22, Issue 8, August 1890, pg. 177. (The article includes a sketch of the machine; text of article in digital images viewed at American Memory, Library of Congress.)

- Conveyor Belt in stone yard in Arizona (Photograph) (Stone In Arizona, by Roland C. Townsend, Consulting Geologist, Phoenix, Arizona, 1961, pp. 13.

The photograph caption on pp. 13 states: “Conveyor from stone cutting house.”

- Crane – “The Fifty Ton Crane of the Lerouville Quarries,” in Scientific American Supplement, August 12, 1893.

-

Crane Builders – the Morgan Engineering Company, Alliance Ohio, Advertisement (Harper’s Weekly, April 23, 1904, pp. 643)

The Morgan Engineering Company, Alliance, Ohio, U.S.A. The largest crane builders in the world. Manufacturers of Steam hammers, rolling mill machinery, punches and shears, hydraulic machinery, roller tables, disappearing gun carriages, special machinery, mortar carriages, electric charging machines for Siemens-Martin, soaking pit and horizontal furnaces.

-

Crane – “Electric Crane for a Marble Yard” (The C. D. Jackson & Co., of New York), Stone An illustrated monthly magazine Devoted to Stone, Marble, Granite, Slate, Cement, Contracting, and Building, Magazine, Frank W. Hoyt, Publisher, New York, December 1903, pp. 124-126.

(excerpt from the article)

“Electric cranes are now being quite generally introduced in large stone and marble yards in place of hand power cranes, and power cranes of other types. The extreme ease with which electric current is carried from either street car or other electric power lines, and the amount of intricate mechanism which the few simple wires will do away with, lead a great many proprietors of marble yards to introduce electricity for cranes….”

“The crane that is shown is in the yard of C. D. Jackson & Co., New York. It was installed by the Northern Engineering Works, crane builders, Detroit, Mich.….”

- Crane – Traveling Crane – “Steam Stone Works” (at the Barr, Thaw & Fraser, Hoboken, New Jersey, Plant), in Scientific American, Vol. LXVI, No. 6, New York, February 6, 1892, pp. 89.

- Crane – “Traveling crane covering 1100 feet” – from Colorado Slate, the Colorado Slate Company, General offices: 320 Fifth Avenue, New York City, Quarries: Marble, Colorado, 1908.

- Craneway – “The craneway and finishing works, South Dover Marble Co.” in “The Marble Industry in New York State,”Mine and Quarry, February 1907, pp. 100. (History and photographs of the South Dover Marble Company located at Wingdale, New York)

- The Crump and Brereton Rotary Quarrier and Stone Shaper (October 1884) (The article includes a sketch: "The Crump and Brereton Rotary Quarrier and Stone Shaper.") The Manufacturer and Builder, Vol. 16, Issue 10, October 1884, pg. 229. (Article in digital images viewed at American Memory, Library of Congress.)

- "The Crump and Brereton Rotary Quarrier and Stone Shaper" (December 1884) Quarrying Notes – The Manufacturer and Builder, Vol. 16, Issue 12, December 1884, pgs. 275-276. (text and diagram of the machinery) (Article in digital images viewed at American Memory, Library of Congress.)

- Derrick in Use in a Quarry (YouTube video)

- Derricks – “The First Derrick,” from Stone Magazine,

March 1925, Vol. XLVI, No. 3, pp. 169.

“‘Give me a place to stand and I will move the earth.’” – Archimedes.

“Hiero, king of Syracuse, learning of Archimedes’ remark, is recorded in history as having requested a demonstration to illustrate his contention that a very great weight could be lifted by a small force. Archimedes, who had been experimenting with a crude form of block and tackle appeared before the king and performed the same experiment that first had caused him to give voice to his claim. Whether he lifted a great block of stone or a tree trunk, history is not clear, but the fact remains that Archimedes was the pioneer in the field of cranes and derricks. Previous to the time of Archimedes the lifting and moving of huge stones was chiefly a question of man power and greased ways. Archytias, a deciple (sic) of Pythagoras, invented the single pulley and it was through a multiplication of pulleys that Archimedes somewhat later demonstrated his theory of the weight lifting. It might be said, in passing, that it was Archimedes, who upon discovering that his body displaced water, ran from his bath crying out the news of his discovery. The Early Greeks and Romans were well acquainted with the block and tackle, while during the Middle Ages it was used extensively to lift heavy loads. Working sketches of hoists, blocks and tackle and derricks in many forms are contained in the sketchbooks of Leonardo da Vinci (1452-1519), the Florentine artist and architect, as well as engineer, who exercised such a pronounced influence upon the art and architecture of his time. But it was not until the age of steam that hoists and derricks really came into their own and began to be perfected in the form that we know them today. It was but a step to make them applicable to electric as well as steam power and it is with the latter that the stone industry is concerned, although quarries still use steam derricks to a great extent, due to the remoteness of many of their deposits from central electric energy plants. Thus from the first locomotive cranes built in England about 1850 or perhaps a little later, crane and derrick manufacturers have sought to meet the requirements of every industry. In small stone yards and mills hand cranes are still in use, but in the larger plants all stone is moved by means of the overhead electric traveling cranes, which are more than mere cranes, but rather suspension bridges of great lifting power and freedom of motion that make it possible to employ them in almost every conceivable manner for lifting and shifting of both the quarry blocks and the finished materials. They are as indispensable to the mill owner as are the pneumatic tools to the carver and the sculptor.”

- Derrick from The Story of the Rock of Ages, Boutwell, Milne & Varnum Company, Montpelier, Vermont, written and compiled by Athol R. Bell, 1925.

- Diamond Cutting Machine – The Marble Industry of Vermont, Free Press Printing Co., Burlington, Vermont, No date of publication – early 1920s

“The rim of this saw contains 125 diamonds. They are embedded in steel, and when the exposed corner becomes dull the stone is broken out and given a new setting. A saw of this kind, if given plenty of water, will cut its way through the hardest marble.”

- Dimension Stone Quarrying – The Blasting Process (April 1893) The Manufacturer and Builder, Vol. 25, Issue 4, April 1893, pg. 86. (Text of article in digital images viewed at American Memory, Library of Congress.)

- Double-Gang Channeling Machine for Sandstone (January 1889) The Manufacturer and Builder, Vol. 21, Issue 1, January 1889, pg. 13. (The article includes a sketch: "The Wardwell Double-Gang Quarrying Machine for Grit Sandstone.") (Article in digital images viewed at American Memory, Library of Congress.)

- “Double Head Planer and Moulding Machine,” in The Monumental News, April 1895.

-

Drills

-

Diamond Drills – “Boring Blast Holes with a Diamond Drill,” from Mine and Quarry Magazine, the Sullivan Machinery Company, Chicago, Illinois, April 1914, pp. 810-811.

- Drill Bit Shapes – “The Proper Shape for Rock Drill Bits,” written for Mine and Quarry by D. J. O’Rourke, Claremont, New Hampshire, Vol. 3, No. 3, June 1908, pp. 220-224.

- Drill Bits for Rock Drills – “Bit for Rock Drills” from the “Recent Inventions” section of The Monumental News, March 1906, pp. 243. (The section on “Coloring Natural Stones” is also included.)

- Drilling Machine – “Improved Machine for Drilling Stone,” in Scientific American, A weekly journal of practical information, art, science, mechanics, chemistry, and manufacturers, New York, June 20, 1868.

- An Electric Drill for Quarry Work (June 1893) (The article includes three sketches; one is "General Electric Company's Electric Percussion Drill.") The Manufacturer and Builder, Vol. 25, Issue 6, June 1893, pg. 134. (Text of article in digital images viewed at American Memory, Library of Congress.)

- An Electrically-Operated Tool for Dressing and Carving Stone, etc. (April 1893) The Manufacturer and Builder, Vol. 25, Issue 4, April 1893, pg. 87. (Text of article in digital images viewed at American Memory, Library of Congress.)

-

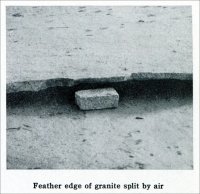

Plug Drills with Air Compressors – “Cleaving Granite by Compressed Air,” by J. E. Schultz, Houston Building, Knoxville, Tennessee, in Mine and Quarry, Sullivan Machinery Company, Chicago, Illinois, Vol. VII, No. 4, July-August 1913, pp. 744-749.

-

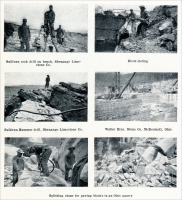

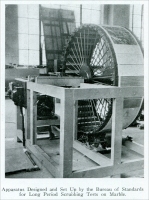

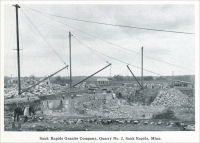

Plug Drills & Tripod Drills (ca. 1916) – “Development of the Sauk Rapids Granite Company” (Sauk Rapids, Benton County, Minnesota), by Stanley G. Harwood, Mechanical Engineer, 2044 Aldrich Avenue, South, Minneapolis, Minnesota, in Mine and Quarry, Sullivan Machinery Company, Chicago, Illinois, Vol. IX, No. 2, January 1916, pp. 898-903.

The article begins: “The Sauk Rapids Granite Company is situated at Sauk Rapids, in Benton County, south central Minnesota, four miles from St. Cloud. This company, one of the youngest in the Minnesota granite district, was organized for the purpose of carrying on quarrying and finishing operations on a large scale, to the end that efficient handling of the quarry product, from monumental stock to crushed rock, might be attained….”

- Rock Drills (ca. 1903) – “How to Run Rock Drills,” in Stone, An illustrated monthly magazine devoted to Stone, Marble, Granite, Slate, Cement, Contracting and Building, Frank W. Hoyt, Publisher, New York, Vol. XXVII, No. 2, December 1903, pp. 132-133.

- (End of the “Drills” section.)

- Equipment & Tools used in Granite Quarrying – “Granite extraction and processing” GaGranite.com (YouTube video)

- “Electricity in the Mining of Marble,” in Electrical World and Engineer, Vol. XLVI, No. 8, New York, August 19, 1905, pp. 298.

- The Granite City Polishing Machine (March 1892) The Manufacturer and Builder, Vol. 24, Issue 3, March 1892, pg. 63. (Article in digital images viewed at American Memory, Library of Congress.)

- Grinding Machine for stone in operation (YouTube video)

- Grindstones – “Moore County Grit” (the North Carolina Millstone Company, located in Moore County, North Carolina), in the Scientific American, Vol. XLVIII, No. 19, May 12, 1883, pp. 294.

The article begins: “The peculiar formation of this stone, and its remarkable adaptability to grinding corn meal, has, in a comparatively short time, been thoroughly brought to the attention of the milling world. In Moore County, North Carolina, located about in the center of the State, this conglomerate was discovered by the early settlers, and was known to exist in a well-defined vein for a distance of nearly two miles, and was first worked in several places by them for their own use in grinding corn meal, and as sought for in every section of the State, and hauled in wagons long distances….”

“About four years ago the entire vein was purchased by the North Carolina Millstone Company, and for the first time since its discovery, improved machinery and appliances were put to work in quarrying and developing this grit….”

- Grindstones (December 1888) The Manufacturer and Builder, Vol. 20, Issue 12, December 1888, pg. 275. (Article in digital images viewed at American Memory, Library of Congress.)

- “Grindstones – Their Actual and Possible Uses,” Scientific American, June 20, 1868.

-

Guillotine Stone Cutter in Sandstone Quarry (Photographs) (Stone In Arizona, by Roland C. Townsend, Consulting Geologist, Phoenix, Arizona, 1961, pp. 13)

The photograph caption on pp. 13 states: “Guillotine stone cutter in quarry of Coconino sandstone.”

The photograph caption on pp. 13 states: “Close view of guillotine cutting Coconino sandstone.”

- Hacking Machine (guillotine-like stone cutting machine in operation) (YouTube video)

-

Hammer Drills (circa 1906) – “Westerly Granite” (Rhode Island), from “Westerly Granite” (Rhode Island), Mine and Quarry, Sullivan Machinery Company, Chicago, Illinois, Vol. VII, No. 2, January 1913, pp. 690-694.

The article begins: “One of the oldest and most widely known quarry districts in New England is that of Westerly, R. I., and vicinity, from which comes the stone commonly known as ‘Westerly Granite.’ Westerly is situated at the extreme western edge of the state, on the Atlantic coast, five miles from Watch Hill. A few miles away is Bradford, formerly known as Niantic, where some of the quarries are situated.

“Some of the Westerly quarries are on a ridge running east and west, about a mile northeast of the town…Other quarries are a mile southeast of Westerly…Granite was quarried in this neighborhood as early as 1846, which was the date of opening of the first quarries, now owned by the Smith Granite Company and the New England Granite Co. The Crumb Quarry was opened in 1857. More recent openings are those of the Newall Quarry, 1883, and the Klondike quarry, 1897….”

- Hammer Drills (circa 1907) – “Channeling Granite with Hammer Drills,” in Mine and Quarry Magazine, Sullivan Machinery Co., Chicago, Illinois, Vol. 1, No. 4, February 1907.

- Hammer Drills (circa 1911) – “Quarrying with Hammer Drills,” by William McKearin and R. S. Hutchison, Mine and Quarry, Vol. VI, No. 1, August 1911, pp. 537-540.

- Hammers - the Hammer Museum in Haines, Alaska, presented by Dave Pahl. (Includes a virtual tour of the museum hammers.)

- Hand carving flowers on marble memorial with a power tool (The following photograph is from one of the Vermont Marble Company, World’s Largest Marble Exhibit, Proctor, Vermont Postcard Folders Click on the pdf link in the preceding sentence if you want to see the rest of the postcard photographs in the folder.)

-

Harrison’s Magazine, May 1929, Harrison Supply Company, Inc., Boston, Massachusetts. Contributed to the Internet Archive by Mark Stansbury, Trowel and Masonry Tool Collector Resource.

-

Harrison’s Magazine, October 1929, Harrison Supply Company, Inc., Boston, Massachusetts. Contributed to the Internet Archive by Mark Stansbury, Trowel and Masonry Tool Collector Resource.

-

Harrison Supply Company, Inc., Catalogue Number Five, 1924, Boston, Massachusetts. Contributed to the Internet Archive by Mark Stansbury, Trowel and Masonry Tool Collector Resource.

- Hoisting Stone in Quarries, The Manufacturer and Builder, Vol. 2, Issue 7, July 1870, pp. 198.

- “Horses,

Oxen and Granite,” (in Barre, Vermont), (online

article) by Paul Wood, January 7, 2008, in the Barre Montpelier

Times Argus.

The time period covered in this article is during the early 1800s.

Key words in article: Adamant Quarries, Montpelier, Vermont; block and tackle; boom derrick; clog chains; John Crouse of Syracuse, New York; Fayette Cutler, Barre, Vermont; double runner sleds; freight Tariffs; Joseph Glidden, Mark Glidden;granite quarries; granite sheds; horse sweep; Jones Brothers, Vermont; “New Hampshire Horses,” railroads; ramp, rollers; single-drum winch; skids; spur track; St. John the Devine Cathedral, New York City; Stanford Mausoleum; wagon pulled by horses and oxen teams, wagons.

- How Granite Columns are Polished (March 1884) The Manufacturer and Builder, Vol. 16, Issue 3, March 1884, pgs. 59-60. (Article in digital images viewed at American Memory, Library of Congress.)

- How Granite is Polished (Granite Pillars) (May 1878) The Manufacturer and Builder, Vol. 10, Issue 5, May 1878, pgs. 102-103. (Article in digital images viewed at American Memory, Library of Congress.)

- Improved Hoisting Engine for Quarrying (November 1884) (The article includes three views of "Improved Hoisting Engine For Quarrying.") The Manufacturer and Builder, Vol. 16, Issue 11, November 1884, pgs. 250-251. (Article in digital images viewed at American Memory, Library of Congress.)

- Improved Hoisting Engines for Quarry Work (February 1886) (The article includes two sketches with two views of the: "Lidgerwood Single-Cylinder Hoisting Machine (without boiler)." The Manufacturer and Builder, Vol. 18, Issue 2, February 1886, pgs. 35-36. (Article in digital images viewed at American Memory, Library of Congress.)

- Improved Hoisting Engine Designed for Quarry Use (May 1888) (The article includes a sketch of "Improved Engine for Quarry Use.") The Manufacturer and Builder, Vol. 20, Issue 5, May 1888, pg. 108. (Article in digital images viewed at American Memory, Library of Congress.)

- Improved Hoisting Engine for Quarry Service (May 1892) (The page includes a sketch of "Improved Hoisting Quarry Engine for Quarry Service.") The Manufacturer and Builder, Vol. 24, Issue 5, May 1892, pg. 110. (Article in digital images viewed at American Memory, Library of Congress.)

- Improved Quarrying Machinery (March 1885) (The article includes a sketch of "Rand's 'Little Giant' Rock Drill.") The Manufacturer and Builder, Vol. 17, Issue 3, March 1885, pgs. 59-60. (Article in digital images viewed at American Memory, Library of Congress.)

- Improved Quarrying Machinery (January 1887) The Manufacturer and Builder, Vol. 19, Issue 1, January 1887, pg. 11. (includes picture of a quarryman using an "improved quarrying frame") (Article in digital images viewed at American Memory, Library of Congress.)

- The Jeffrey Stone Elevator (July 1894) The Manufacturer and Builder, Vol. 26, Issue 7, July 1894, pg. 159. (Article in digital images viewed at American Memory, Library of Congress.)

- The Knox Blasting System – “Modern Methods of Quarrying,” in Scientific American Supplement, Vol. XXXII, No. 832, New York, December 12, 1891.

|

|

“Sullivan Class 6 ½ Single Gang Marble Channeler.” (pp. 101) |

“The north end of the South Dover quarries. A Sullivan double head channeler is in the center. ( pp. 98) |

|

|

“A Sullivan ‘Z’ Channeler on the Barge Canal, Lockport, New York. |

“Buckeye Quarry of the Ohio Quarries Company, Amherst, Ohio. This company employs 16 Sullivan Channelers.” |

| “Electric crane in a New York Marble Yard.” (C. D. Jackson & Co. of New York, Stone Magazine, December 1903, pp. 124) |  |

| “The craneway and finishing works, South Dover Marble Co.,” Wingdale, New York (from “The Marble Industry in New York State,” in Mine and Quarry, February 1907, pp. 100) |  |

| “Bit for Rock Drills” from the “Recent Inventions” section of The Monumental News, March 1906, pp. 243 |  |

|

|

|

“Starting a 400-foot ledge line with Sullivan Plug Drills.” |

“Sketch showing sectional view of granite splitting by air.” |

|

|

|

|

“Feather edge of granite split by air.” |

“In the finishing plant.” |

“Sullivan Corliss Cross Compound Two Stage Air Compressor, North Carolina Granite Corporation.” |

|

|

“A rush order for large stones; Sullivan Plug Drills at work.” |

Men in the North Carolina Granite Corp. quarry at Mt. Airy. |

|

|

|

“Sullivan Plug Drills at work, Sauk Rapids Granite Company” |

“Sauk Rapids Company, Quarry No. 2, Sauk Rapids, Minnesota” |

“Hoist and Sullivan Angle Compound Air Compressor at No. 2 Quarry” |

|

|

“Sullivan 445-foot Angle-Compound Air Compressor, Quarry No. 3, Sauk Rapids Granite Company” |

“Quarry No. 3, Sauk Rapids Granite Company. Sullivan Tripod Drills at work” |

This article beings: “There are few more striking contrasts between old time and modern methods of doing business than is furnished by what may be called trade literature, that is, the publications put forth in the way of catalogues, price lists, etc. Issues of this kind are no longer confined to a mere enumeration of goods for sale, prices, etc. Invaluable suggestions as to installation, care of equipment, repairs, etc., as well as standard tables, supplement what is purely personal to the house making the issue. As an illustration in point, there are the following instructions for users of rock drills, issued by the Sullivan Machinery Company….”

| “‘Moore County Grit’ Portable Corn Mills” from “Moore County Grit” (the North Carolina Millstone Company, located in North Carolina), in the Scientific American, May 12, 1883, pp. 294. |  |

|

|

|

“The Klondike Quarry, Westerly.” (pp. 691) |

“The old way of splitting granite at Westerly.” (pp. 692) |

“The new way, Sullivan Hammer Drills.” ( pp. 692) |

|

|

|

“Plan for channeling steps from a granite block.” (pp. 106) |

“Special broach.” (pp. 107) |

“Sullivan ‘Plug Drill’ on a test run.” at the Jones Bros. quarry in Barre, Vermont (pp. 107) |

- “The Knox System of Quarrying,” by William L. Saunders, in Scientific American, Vol. XXXIII, No. 836, New York, January 9, 1892, pp. 13356-13357

- A Large Quarry Hoisting Engine (May 1893) (This article includes a sketch of a "Ten-Ton Quarry Hoisting Engine, Built by J. S. Mundy of Newark, N. J.") The Manufacturer and Builder, Vol. 25, Issue 5, May 1893, pg. 111. (Article in digital images viewed at American Memory, Library of Congress.)

- Lathe – “White marble pillar (12 x 3 feet) in lathe” − from Colorado Slate, the Colorado Slate Company, General offices: 320 Fifth Avenue, New York City, Quarries: Marble, Colorado, 1908.

- Lettering marble war memorial using hand tool (The following photograph is from one of the Vermont Marble Company, World’s Largest Marble Exhibit, Proctor, Vermont Postcard Folders. Click on the pdf link in the preceding sentence if you want to see the rest of the postcard photographs in the folder.)

- The Lewis – The lewis is a tool that is used by a freemason to raise large stones and set them in the desired location. Visit this web site for a thorough description and diagram of the lewis. The web site is presented by Pietre-Stones Review of Freemasonry.

- Manufacturer of Grindstones (June 1894) The Manufacturer and Builder, Vol. 26, Issue 6, June 1894, pg. 135. (The article includes a sketch of "Turning Large Grindstones - Quarry No. 2 West View, Ohio"; article in digital images viewed at American Memory, Library of Congress.)

- Marble – Practical problems which have from time to time perplexed the producers of marble (in 1925) – “A Study of Practical Problems for the Marble Industry,” by D. W. Kessler, in Stone, Vol. XLVI, No. 8, August 1925, pp. 479-481.

- Marble Channeling Machine – The Marble Industry of Vermont, Free Press Printing Co., Burlington, Vermont, No date of publication – early 1920s

“The electric channeling machine runs on a movable track which is placed on the floor of the quarry. By continual pounding on the marble, this machine sinks a narrow groove to a depth of several feet, making it possible to take out blocks of uniform shape and size. The cutting is done by five chisel-pointed drills, clamped together in a row and attached to the end of a steel bar.”

- The McDonald Stone Dressing Machine (January 1885) (The article includes a sketch of the machine.) The Manufacturer and Builder, Vol. 17, Issue 1, January 1885, pg. 12. (Article in digital images viewed at American Memory, Library of Congress.)

- “Memorializing the Civil War Dead: Modernity and Corruption under the Grant Administration” (pdf), by Bruce S. Elliott, in Markers XXVI, Association for Gravestone Studies, 2011, pp. 15-55. (Reprinted with permission of the Association for Gravestone Studies.)

This article describes the need to mass produce the Civil War headstones rather than by individual stone carvers. Contracts for the headstones and bases were given out to several different quarries and companies in Vermont, Massachusetts, New York, Pennsylvania, Kansas, and Tennessee. The need for large numbers of markers also increased the use of the sandblasting process to speed up carving the names on the stones. Both mass production the sandblasting process caused great changes in the work of the stone carvers, which led to demands by the stone workers’ unions, such as the eight-hour work day.)

- Modern Explosives (March 1894) The Manufacturer and Builder, Vol. 26, Issue 3, March 1894, pg. 62. (Article in digital images viewed at American Memory, Library of Congress.)

- Modern Stone Quarrying - The Channeling Process (October 1884) The Manufacturer and Builder, Vol. 16, Issue 10, October 1884, pgs. 230-231. (Article in digital images viewed at American Memory, Library of Congress.)

-

Moulding Machine – “Steam Stone Works” (at the Barr, Thaw & Fraser, Hoboken, New Jersey, Plant), in Scientific American, Vol. LXVI, No. 6, New York, February 6, 1892, pp. 89.

- “A New ‘Duplex’ Channeler for Oölitic Limestone,” by C. J. Levey, from Mine and Quarry Magazine, Sullivan Machinery Co., Publisher, Chicago, Illinois, Vol. VII. No. 2, January, 1913.

- Paving Block Cutters in 1913 – “Profitable Trades Are Plentiful; Good Chance in Granite Work,” by C. P. M’Donald, “San Francisco Call,” Vol. 114, No. 36, July 6, 1913, pp. 33.

- Planer – “Planer at work in the cut stone department of the Tenino Stone Company’s plant at Tenino, Washington.” in “Tenino, Washington,” by Miss Blendine Hays, “Tenino, Washington,” The Coast: Alaska and Greater Northwest, Vol. 17, No. 3, March 1909, pp. 199-204, The Coast Publishing Co., Seattle, U.S.A.

- Planing marble flutes in large column (The following photograph is from one of the Vermont Marble Company, World’s Largest Marble Exhibit, Proctor, Vermont Postcard Folders (pdf) Click on the pdf link in the preceding sentence if you want to see the rest of the postcard photographs in the folder.)

- Plug Drill “Type 24” made by the Livingston Manufacturing Co. Advertisement (from The Monumental News, November 1929, pp. 564)

- Polishing Granite (YouTube video)

-

“Polishing Granite,” in the “Practical Pointers” section of The Monumental News, March 1896. This article begins as follows: “By way of preface to the following remarks upon granite polishing, it should be stated that the discussion is based upon the employment of machines of the most approved type and excellence, several of which are manufactured in Barre, Vt. Illustrations of some of these may be seen in the advertising columns of this journal….”

- Polishing Marble – The Marble Industry of Vermont, Free Press Printing Co., Burlington, Vermont, No date of publication – early 1920s. Polishing marble is also discussed in the 1926 article, “The Romance of Verde Antique,” by Basil B. Walsh, in The Vermonter, Vol. 31, No. 9, 1926, pp. 132. (The photograph below is shown in both articles.)

“The work is all done by a small, whirling disk which is moved about over the watered surface of the stone. The first plate used is coated with carborundum, the second with aloxite, and the third with hone. To complete the process, the plat is covered with felt and applied in conjunction with polishing putty.”

- Polishing Machine for Stone (YouTube video)

- Polishing Marble (Recipes) (October 1889) The Manufacturer and Builder, Vol. 21, Issue 10, October 1889, pgs. 233-234. (Article in digital images viewed at American Memory, Library of Congress.)

- Polishing marble slab (The following photograph is from one of the Vermont Marble Company, World’s Largest Marble Exhibit, Proctor, Vermont Postcard Folders (pdf) Click on the pdf link in the preceding sentence if you want to see the rest of the postcard photographs in the folder.)

- Power Rock Drills & Compressors – “The Manufacture of Power Drills for Mining, Excavating, Etc.,” Scientific American, Vol. XLIII, No. 26, (American Industries. – No. 63), New York, December 25, 1880, pp. 401-402.

- The Pulsometer as a Quarry Pump (January 1885) (The article presents views of "The New Pulsometer" and a view of "The New Pulsometer Applied to Quarry Work.") The Manufacturer and Builder, Vol. 17, Issue 1, January 1885, pgs. 13-14. (Article in digital images viewed at American Memory, Library of Congress.)

- Quarry and Workshop Equipment and Tools circa 1907 – “The Marble Quarries of Carrara,” by Day Allen Willey, in Scientific American, Vol. XCVII, No. 20, New York, November 16, 1907, pp. 353, 361-362.

|

“Planer at work in the cut stone department of the Tenino Stone Company’s plant at Tenino, Washington.” 1909) |

- Quarry Equipment circa 1886 – “Methods of Quarrying and Dressing” − Excerpts from The Collection of Building and Ornamental Stones in the U.S. National Museum: A Hand-book and Catalogue, by George P. Merrill, curator, pp. 285-331. From Annual Report of the Board of Regents of the Smithsonian Institution…Year ending June 30, 1886, 1887.

- Quarry Tools, presented on the Stones Structures of Northeastern United States web site.

- Quarry Workers’ Tools (photograph/section) of “How to Tour the Marble Quarries of Carrara,” by James Martin, on his Guide to Europe Travel web site.

- Quarrying and Working Marble (October 1893) The Manufacturer and Builder, Vol. 25, Issue 10, October 1893, pg. 230. (Text of article in digital images viewed at American Memory, Library of Congress.)

- Quarring Equipment & Tools in the Stone Industries in the United States & Foreign Countries up through 1939 in The Stone Industries: Dimension Stone, Crushed Stone, Geology, Technology, Distribution, Utilization, by Oliver Bowles (Supervising Engineer, Building Materials Section, United States Bureau of Mines), New York: 2nd ed., New York: McGraw-Hill, 1939. (You can view a copy of this book on Internet Archive web site, and you can download a copy of the book to your computer at the link above.)

This book fully covers the United States stone quarry industry up through 1939. There is also a chapter on “Foreign Building and Ornamental Stones.” Below is a listing of the information covered in the chapters. (Many photographs of quarries, etc., are included in this book.)

Part I. General Features of the Stone Industries

Chapter I. Extent and Subdivision. Extent of the Industry – Major Divisions of the Industry – Varieties of Stone Used

Chapter II. Minerals and Rocks. Distinction between Rock and Stone – Relationship of Rocks to Minerals – Rock-forming Minerals – Classification of Rocks – General Distribution of Rocks in the United States.

Chapter III. Factors Governing Rock Utilization. Rock Qualities on Which Use Depends – Importance of Other factors than Quality – Available Markets; Diversification of Products Transportation Facilities – Production Code

Chapter IV. Prospecting and Developing. Prospecting – Stripping – General Methods of Operation – Bibliography

Part II. Dimension Stone

Chapter V. General Features of Dimension-Stone Industries. Definition of Dimension Stone – Principal Uses Requisite Qualities of Dimension Stone – Adaptations of Raw Materials to Use – Complexities in Marketing – Royalties

Chapter VI. Limestone. Definition – Origin – Physical Properties – Varieties – Qualities on Which Use Depends – Uses – Industry by States – Occurrences of Travertine – Quarry Methods – Milling Methods – Limestone Products – Cost of Quarrying and Manufacture – Waste in Quarrying and Manufacture – Utilization of Waste – Limestone Marketing – Bibliography

Chapter VII. Sandstone. Varieties – Composition – Size and Shape of Grains – Cementation – Color – Porosity – Uses – Production – Industry by States – Quarry Methods – Quarry Processes – Yard Service – Sandstone Sawmills and Finishing Plants – The Bluestone Industry – Waste in Sandstone Quarrying and Manufacture – Bibliography

Chapter VIII. Granite. General Character – Mineral Composition – Chemical Composition – Physical Properties Varieties – Related Rocks – Structural Features – Uses – Distribution of deposits – Industry by States – Quarry Methods and Equipment – Milling Methods and Equipment – Market Range – Imports, Exports, and Tariffs – Prices – Bibliography

Chapter IX. Marble. History – Definition – Composition – Origin and Varieties – Physical Properties – Jointing or Unsoundness – Chief Impurities of Marble – Uses – Distribution of Deposits – Production – Industry by States – Quarry Methods and Equipment – Transportation; Equipment and Operation in Mills and Shops – Waste in Quarrying and Manufacture – Marketing Marble – Imports and Exports – Tariff – Prices – Bibliography

Chapter X. Slate. Definition – Origin – Mineralogical Composition – Chemical Composition – Physical Properties – Structural Features – Imperfections – Uses – History of Industry – General Distribution – Production – Industry by States – General Plan of Quarrying – Quarry Operations – Quarry Methods – Yard Transportation – Manufacture of Roofing Slate – Storage of Roofing Slate – The Art of Roofing with Slate – Manufacture of School slates – Manufacture of Mill Stock – Slate Floors – Walks, and Walls – Crushed and Pulverized Slate Products – Waste in Quarrying and Manufacturing – Tests and Specifications – Marketing – Imports and Exports – Tariff – Prices – Bibliography

Chapter XI. Soapstone. Composition and Properties – History – Uses – Origin and Occurrence – Quarry Methods – Milling Processes – Marketing – Rocks Related to Soapstone – Bibliography

Chapter XII. Boulders as Building Materials. Origin and Nature of Boulders – Stone Fences – The Use of Boulders in Buildings

Chapter XIII. Foreign Building and Ornamental Stones. Scope of Discussion – Imports of Stone – Foreign Limestones – Foreign Sandstones – Foreign Granites – Foreign Marbles – Foreign Slates – Bibliography

Chapter XIV. Miscellaneous Rocks and Minerals Used for Building and Ornamental Purposes. Agalmatolite – Alabaster – Amazonite – Catlinite – Clay – Diatomite – Tripoli and Pumice – Fluorite – Jade – Labradorite – Lapis-lazuli – Malachite and Azurite – Meerschaum – Mica Schist – Porphyry – Quartz; Snow and Ice – Sodalite – Bibliography

Chapter XV. Deterioration, Preservation, and Cleaning of Stonework. Deterioration of Stone – Preservation of Stone – Cleaning Stone – Bibliography

Part III. Crushed and Broken Stone

Chapter XVI. General Features of the Crushed-Stone Industries. History – Types and Values of Stone Used – Crushed Stone and Dimension Stone Contrasted – Uses of Crushed Stone – Competition – Markets – Transportation – Prices – Royalties – Capital Required

Chapter XVII. Crushed and Broken Limestone. Types of Stone Included – Extent of Industry – Uses of Crushed and Broken Limestone – Uses for Which Physical Properties are Most Important – Uses for Which Chemical Properties are Most Important – Uses of Dolomite and High-magnesian Limestone – Industry by States – Quarry Methods and Equipment; Bibliography

Chapter XVIII. Crushed and Broken Stone Other Than Limestone. General Features – Uses – General Distribution and Value – Industries by States – Quarry Method and Equipment – Marketing – Bibliography

- Quarrying Sandstone by Channeling and Wedging (March 1891) (The article includes a sketch with the caption: "Quarrying with Channeling and Wedging.") The Manufacturer and Builder, Vol. 23, Issue 3, March 1891, pg. 57. (Text of article in digital images viewed at American Memory, Library of Congress.)

- Quarrying with the Ingersoll Bar Channeler ( July 1891) The Manufacturer and Builder, Vol. 23, Issue 7, July 1891, pg. 159 (Photograph of quarry and quarry workers and text of article (Text of article in digital images viewed at American Memory, Library of Congress)

- Railway – Electric Railway used to transport marble in underground marble quarries – from The Marble Industry of Vermont, Free Press Printing Co., Burlington, Vermont, No date of publication – early 1920s.

“The underground marble quarries at West Rutland are 2,000 feet long and have a maximum width of 700 feet. An electric road which operates on the floor of the quarry is 300 feet below the surface and stretches for 800 feet out into the tunnel. Connecting with this electric railway and leading up to the ground level is a cable track which is 500 feet long and rises at an angle of forty-five degrees.”

- Rock Drill & Air Compressor (circa 1893) – “Improved Rock Drill and Air Compressor,” in Scientific American, Vol. XXXV, No. 893, New York, February 11, 1893, pp. 14266-14267

- “Rock-Drilling Machine,” by John Darlington, Scientific American Supplement, No. 103,Vol. IV, No. 103, New York, December 22, 1877.

- Rock Drills (circa 1907) – “The Mechanical Sharpening of Rock Drill Steel,” by Matt. Brodie, M.E., Mine and Quarry, Vol. 1, No. 4, February 1907.

- Rock Drills – “Rock Drills for Department Stores,” from Mine and Quarry,” Sullivan Machinery Co., Chicago, Illinois, April 1913, pp. 725.

-

Rock Drills – Sullivan “Hy-Speed” Rock Drill in a New England Granite Quarry on the front cover of Mine and Quarry, Sullivan Machinery Co., Chicago, Illinois, April 1913.

- “Rubbing bed and saw gangs in mill” – from Colorado Slate, the Colorado Slate Company, General offices: 320 Fifth Avenue, New York City, Quarries: Marble, Colorado, 1908.

- Rubbing Bed for Marble – The Marble Industry of Vermont, Free Press Printing Co., Burlington, Vermont, No date of publication – early 1920s

“The rubbing bed is a large, horizontal, castiron disk, made to revolve in a frame and so constructed as to allow sand and water to play over its surface. After the mills have reduced the marble to the required size, it is placed on the rubbing beds, where it is held in a fixed position until the corners are perfect and the surfaces smooth.”

- Rubbing marble to size (The following photograph is from one of the Vermont Marble Company, World’s Largest Marble Exhibit, Proctor, Vermont Postcard Folders (pdf) Click on the pdf link in the preceding sentence if you want to see the rest of the postcard photographs in the folder.)

- Sand Blasting

- “Sand-Blast: Its Place in Monument Industry,” Sand as an abrasive – The first of a series of articles on the Sand-Blast,” by Francis H. Scantlebury, Pantentee, from Granite Marble & Bronze, October 1920, pp. 35-36.

-

“Maximum Efficiency with the Sand Blast,” A Series of Papers on the Possibilities and Limitations of the Sand Process. X. Some Typical Examples of Current Sand Blast Ornament, by Roderic Stuart, from The Monumental News, Vol. XXXIII, No. 5, May 1921, pp. 348-350.

First page of the article, “Sand-Blast: Its Place in Monument Industry,” October 1920, pp. 35

Second page of the article, “Sand-Blast: Its Place in Monument Industry,” October 1920, pp. 36

- Saws Used on Stone (wire, blades, chains, lazers, etc.)

- Blockcutter Saw (YouTube video)

- “Bridge Saw Machine PCruz ‘Classic’” (YouTube video) “Machine designed for the cutting to size of the natural stone. Adaptable to cut marble or granite….”

- Bridge Sawing Machine – “River Bridge Sawing Machine” (YouTube video)

- “Chain Saw Machine in Qs4000d Sultante of Oman” (YouTube video)

- Chain SW Machine Qs4000d: Head of The Blade

- Chain Saw Machine Cutting in Vertical Position - Carribean Island (YouTube video)

- Chain Saw Qs4000d - Vertical Cut (Particular) (YouTube video)

- Chain Saw Machine Cutting n Vertical Position - Carribean Island (YouTube video)

- Chain Saw – “Dazzini Chain Saw Machine” (YouTube video) “Horizontal cut in Carrara quarry”

- Chain Saw Machine (YouTube video) “Marble Chain Saw Machine”

- Chain Saw Machine Vision Back - Dazzini Chain Saw (YouTube video)

- Chain Saw – “Fantini Chainsaw Machines Cutting Equipment on A Tractor” (YouTube video)

- Chain Saw – “Fantini Chainsaw Machines mod. 20.90.wmv” (YouTube video)

- 2 Chain Saw Machine Qs4000d in Vertical Parallel Cuts (YouTube video)

- Circular Cutter – “Cutting Columns From Solid Rock” (at Charleroi, Belgium, circa 1906), in The Literary Digest, Vol. XXXII, No. 16, New York, April 1906, pp. 612-613. (This article begins: “A special electric drill or cylindrical cutter for sinking shafts in rock by taking out solid columns of stone is now built by the Société de Constructions Electriques at Cherleroi, Belgium. The essential part of this machine, as described by L. Ramakers in The Scientific American (New York, March 31), is an iron-plate cylinder 140 inches in height and 36 ½ in diameter, at the base which is mounted a cylindrical knife 12 inches in height, bearing alternate teeth upon concentric circumferences….”)

- Cutting a block of Palumbo Marble (YouTube video)

- Cut Stone Plant of H. J. Horner & Sons, Newark, New Jersey – “Well Equipped Cut Stone Plant,” in Stone, An Illustrated Magazine, July 1924. (The H. J. Horner & Sons Cut Stone Plant in Newark, New Jersey)

- Cutting Blocks of Granite - NT100 cutting centre with 100 disks for granite (YouTube video)

- Cutting Granite (YouTube video) “Video of Gold and Silver Granite cut from the stone slab in various granite slabs. Produced by: Green Coconut Production of Ideas”

- Cutting Granite (YouTube video) “Video of cutting Gold and Silver Granite into smaller sizes by Green Coconut Production of Ideas

- Dazzini Equipment Cutting Dry, Without Using Water in an Egyptian Quarry (YouTube video)

- Diamond Cutting Chain – “marble cutting diamond chain” at Carrara (YouTube video) “Here's how to cut once the marble with an ‘old’ diamond saw”

- Diamond Wire Saw – “Cutting with Diamond Wire” (YouTube video)

- Diamond Wire Saw S850eg in Carrara Quarry in Italy (YouTube video)

- Diamond Stone-Sawing Machine (February 1892) The New England Magazine, Vol. 24, Issue 2, February 1892, pg. 39. (The article includes a sketch of the machine) (Article in digital images viewed at American Memory, Library of Congress.)

- "Diamond Wire for Cutting Hard Rock," Dimensional Stone, Vol. 5, No. 2, O. Cia and R. Mancini, pp. 24-27, 1989.

- "The Diamond Wire Saw," Dimensional Stone, Vol. 6, No. 8, A. C. Hawkins, et al., pp. 44-50, 64, 1990.

- Diamond Wire Saw S850eg Cutting Granite (YouTube video – present-day saw)

- Diamond Wire Saw Trial #1 (10-20-2008) (YouTube video) “Test cut for Ameron Concrete large wall pipe.”

- Double Edge Cutting Machine – “Double Edge Cutting.mov” (YouTube video) “The double edge cutting machine is ideal for cutting two edges of any stone tiles, at the same time…”

- Double Pillar Multi Blade Machine (YouTube video) “gives more than double production than single blade cutter.in all type of hard and soft materials.”

- Edge-cutting stone machine in operation (YouTube video)

- Electric Quarry Saw (circa 1926) – “The Romance of Verde Antique,” by Basil B. Walsh, in The Vermonter, Vol. 31, No. 9, 1926, pp. 130-136.

- Excavator Rocksaw Cutting Walls....Sumitomo SH350 (YouTube video) “Stratti Rocksaw and Design is the premier Rocksaw manufacturer in the world for ‘Hard Rocksaws’ and our patented ‘Twin Rocksaw’ design.”

- Gang Saw – “JumboMatic Block Granite GangSaw: Gaspari Menotti” (YouTube video)

- Gang Saw 80 PCruz (YouTube video) “Multi-Saws machine for high production for sawing of blocks. Movement of the articulated arms of the saw. Minimizing the friction of the saws….”

- Gang Saw 80 PCruz (YouTube video) “Multi-Saws machine for high production for sawing of blocks….”

- Gang Saw Machines (Wardwell, 1893) – Circular Descriptive of the Wardwell Stone Channeling and Quarrying Machines, Issued by the Steam Stone Cutter Company, Proprietors of Patents and Sole Manufacturers, Rutland, Vermont, 1893.

- “Gang saw machinery in mill” − from Colorado Slate, the Colorado Slate Company, General offices: 320 Fifth Avenue, New York City, Quarries: Marble, Colorado, 1908.

- Gang Saw for Cutting Marble Blocks – The Marble Industry of Vermont, Free Press Printing Co., Burlington, Vermont, No date of publication – early 1920s

“The modern marble mill is constructed of steel and is divided up into stalls or compartments, any one of which will accommodate a large quarry block. The sawing is done by smooth iron bands, set in a moving horizontal frame and acting in conjunction with sand and water. While the soft strips of iron are being dragged to and fro across the marble, the water is pouring down over the top of block, bringing the particles of sand which are to serve as teeth for saws.”

- Gang Saw for Marble – “SFERA Gangsaw for Marble” (YouTube video) “SIMEC SpA - SFERA gangsaw for marble”

- Gang Saw for Marble – “M40 Gangsaw for marble” (YouTube video)

- Gang Saw – “Record Gang Saw” (in operation) (YouTube video)

- Gang Saw – “SIMECWIRE diamond wire granite gang-saw” (YouTube video)

- Granite Cutting 04/30/09 (YouTube video)

- Gang Saw – Improved Double-Gang Stone-Channeling and Quarrying Machine (November 1888) (The article includes a sketch of "The Double-Gang Stone-Cutting and Quarrying Machine.") The Manufacturer and Builder, Vol. 20, Issue 11, November 1888, pgs. 251-252. (Article in digital images viewed at American Memory, Library of Congress.)

- Gang Saw – Improved Gang Saw for Stone-Sawing (the Merriman Screw Gang Saw) (October 1888) The Manufacturer and Builder, Vol. 20, Issue 10, October 1888, pg. 226. (The article includes a sketch of the gang saw.) (Article in digital images viewed at American Memory, Library of Congress.)

- Gang Saw – Improved Stone Sawing and Quarrying Machine (August 1892) (This article includes a sketch of "Improved Stone-Sawing and Quarrying Machine.") The Manufacturer and Builder, Vol. 24, Issue 8, August 1892, pg. 183. (Text of article in digital images viewed at American Memory, Library of Congress.)

- Hard Rock Cutting - Stratti Saws – Case CX 330 (YouTube video by Rock Saw Holdings Pty.)

- Horizontal Drilling in Empty Space! (YouTube video)

- Horizontal Cut by Diamond Wire Saw S850e (YouTube video)

- Improved Gang Saw for Stone-Sawing (the Merriman Screw Gang Saw) (October 1888) The Manufacturer and Builder, Vol. 20, Issue 10, October 1888, pg. 226. (The article includes a sketch of the gang saw.) (Article in digital images viewed at American Memory, Library of Congress.)

- Improved Stone Sawing and Quarrying Machine (August 1892) (This article includes a sketch of “Improved Stone-Sawing and Quarrying Machine.”) The Manufacturer and Builder, Vol. 24, Issue 8, August 1892, pg. 183. (Text of article in digital images viewed at American Memory, Library of Congress.)

- Laser Bridge Cutting Machine For Marble & Granite (Infrared) (YouTube video) “For cutting tile and slab…”

- Marble Cutter Diamond con Sierras (YouTube video) “Marble cutting machine, this machine has the function of cutting large marble blocks to turn them into several plates”

- Milling Machine – “ShapeMill NCF 1100/2T - 1400/2T - 5 axis CNC stone machining milling” (YouTube video) “Breton ShapeMill NCF 1000/2T is a CNC milling centre with 5 interpolated axes designed for cutting, contouring and turning operations....”

- Quarry Stone Cutting Machine (YouTube video)

- “Rock Saw” (YouTube video)

- “Rock Saw” (YouTube video)

- Rock Saw Video (YouTube video) “Rock Tools Diamond Saw Cutting Concrete and Rebar” Rock Tools, Inc.

- Rock Saw Video (in a quarry) (YouTube video) “Watch the Rock Tools saw in action.”

- Saw Cutting Granite – “Rai Saw Cutting Granite” (YouTube video)

- Saw used at the main Knowles granite quarry, Madera County – If you would like to see the rest of the photographs from this quarry tour, visit the “Raymond/Knowles, Madera County – the main Knowles Quarry (Granite) – Quarry Blast Mid-quarry” section of our web site. (The following photographs of the stone saw are from a tour for the Yosemite Rangers of the main Knowles granite quarry site and the Raymond Museum on February 21, 2012. (These photographs were contributed by Lynn Northrop of the Raymond Museum.)

- Sawing a Marble Block (YouTube video) Palumbo Marmi

- Sawing Granite (February 1877) The Manufacturer and Builder, Vol. 9, Issue 2, February 1877, pg. 40. (Article in digital images viewed at American Memory, Library of Congress.)

- Sawing Machine – A New French Sawing Machine ("A new stone-cutting machine, with diamond teeth.") (April 1891) The Manufacturer and Builder, Vol. 23, Issue 4, April 1891, pg. 81. (Text of article in digital images viewed at American Memory, Library of Congress.)

-

Sawing Machine – “Steam Stone Works” (at the Barr, Thaw & Fraser, Hoboken, New Jersey, Plant), in Scientific American, Vol. LXVI, No. 6, New York, February 6, 1892, pp. 89.

- “A Machine for Sawing Granite: A most useful adjunct in the New England Quarries,” by Frank C. Perkins, Scientific American Supplement, July 27, 1912, pp. 57-58.

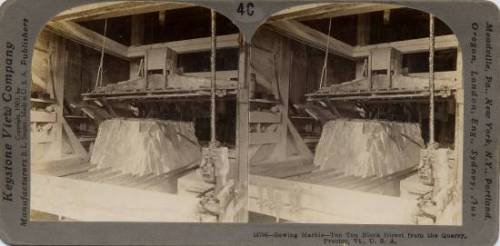

- Sawing Marble - Ten-Ton Block Direct from Quarry, Proctor, Vermont

(Keystone View Co. photograph and text, 1913)

- Sawing marble with diamond saw (The following photograph is from one of the Vermont Marble Company, World’s Largest Marble Exhibit, Proctor, Vermont Postcard Folders (pdf) Click on the pdf link in the preceding sentence if you want to see the rest of the postcard photographs in the folder.)

- Steam Shovel from The Story of the Rock of Ages, Boutwell, Milne & Varnum Company, Montpelier, Vermont, written and compiled by Athol R. Bell, 1925.

- Stone Cutter from Xiamen Bestlink (YouTube video) “BL series stone sawing machine (stone cutter) is the specialized quarrying machine for using circular saw to cut stone blocks….”

- Stone Cutter Machine Model (YouTube video) “This is a model of a stone cutter machine. The blade is mounted on a XZ Cartesian robot.”

- Stone Cutting Machine (YouTube video) “We developed this New Product in Korea. This Machine uses 50 cutting saws which are size of 65 inches at one time. This Machine can produce 300 square meters stone slice in one day….”

- Stone-Cutting Machine – Cantedora (YouTube video) “Ovalines Making Machine Marble, Onyx, Travertine and Cantera” (YouTube video)

- Stone Cutting Machine - Khaled Zaidan (YouTube video)

- Stone Cutting Machine (YouTube video)

- Stone Cutting Machine (YouTube video) “Cut stone cut stone and rock cut stone method”

- Stone Quarry Cutting Machine (YouTube video)

- “Stone-Sawing Machinery,” in the Scientific American Supplement, No., 54, Vol. III, No. 54, New York, January 13, 1877, pp. 850-853.

- Stone Saw - CPG 3500 (YouTube video) “Machine for cutting blocks of marble or granite with a 2500 to 3500mm.”

- “Stone Sawing” circa 1870 (From Byrne’s Handbook for the Artisan), from The Scientific American, September 3, 1870, pp. 149.

- Stone-Sawing and Its Machinery (December 1884) (The article includes a sketch of a "Modern Stone-Sawing Machine.") The Manufacturer and Builder, Vol. 16, Issue 12, December 1884, pg. 276-277. (Article in digital images viewed at American Memory, Library of Congress.)

- Stone-sawing Machinery –“Improved Stone-Sawing Machinery,” Scientific American, Vol. XXXV, No. 13, New York, September 23, 1876, pp. 191.

- Stratti Rocksaw ..... www.rocksaw.com.au (YouTube video by Rock Saw Holdings Pty Ltd.)

- Stratti Dual Rock Saw...John Deere 350D Excavator March 2008 (YouTube video)

- Stratti Twin Rocksaw...April 2008...CASE CX330 (YouTube video by Stratti Rock Saws)

- Trio of Hilo. Equipment for Making Marble Works diamond wire (YouTube video) “Machine designed for marble figures sculpture type”

- Wedges in use in Arizona sandstone quarry (Photograph) (Stone In Arizona, by Roland C. Townsend, Consulting Geologist, Phoenix, Arizona, 1961, pp. 13.

- Wire Saw – “Dazzini Wire Saw Squaring A Big Blocks” in a Carrara Quarry (YouTube video)

- Wire Saw – “The Helicoidal or Wire Stone Saw,” in Scientific American Supplement, Vol. XX, No. 520, New York, December 19, 1885.

Cut Stone Plant of H. J. Horner & Sons, Lister Avenue, Newark, New Jersey ( 1924)

In the main runway of the cutting department of the stone plant of H. J. Horner & Sons, Newark, New Jersey (1924)

“No. 1, Single Gang Machine, Price $1,400. Net.”

“No. 2, Double Gang Machine, Price $1,600.”

“No. 3, Double Gang Sandstone Machine, Price $1,600. Net.”

“Fig. 1. Battery of Granite Saw Blades in Position.”

“Fig. 2. The Inner and Outer Frame Work of the Granite Saw.”

“Fig. 3. The Outer Framework.”

“Fig. 4. The Saw Blades and Their Pivots.”

“Fig. 5. Granite Block Broken in Two After Having Been Partially Sawed Through.”

“Fig. 6. A Long Granite Beam With Two Faces Finished by the Saw.”

The photograph caption on pp. 13 states: “Quarry in Coconino sandstone, showing wedging, waste, and stone stacked for shipment.”

| The ‘Numa’ Rock Drill Maker and Sharpener from “The Mechanical Sharpening of Rock Drill Steel,” by Matt. Brodie, M.E., Mine and Quarry, February 1907, pp. 104 |  |

|

“Rock Drills for Department Stores,” from “Mine and Quarry,” Sullivan Machinery Co., Chicago, Illinois, April 1913, pp. 725. |

|

|

|

“Fig. 5. Application of Gay’s Stone Saw in a Marble Quarry” |

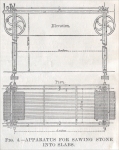

“Figs 1, 2, and 3. Apparatus for Sawing Stone” |

“Fig. 4. Apparatus for Sawing Stone into Slabs” |

- Wire Saw – “Helicoidal or Wire Stone Saw” (pdf), in Scientific American, March 6, 1886.

- Steam Lorry, 1904 – The Old Granite Company, Ltd., Steam Lorry, Enderby, Leicestershire, England, 1904 photograph

- Wire Cord Saw – Quarrying by Wire Cord (June 1891) (The article includes a sketch of machinery used to quarry by wire cord.) The Manufacturer and Builder, Vol. 23, Issue 6, June 1891, pgs. 129-130. (Text of article in digital images viewed at American Memory, Library of Congress.)

-

Wire Saw cutting Coconino Sandstone (Stone In Arizona, by Roland C. Townsend, Consulting Geologist, Phoenix, Arizona, 1961, pp. 13)

The photograph caption on pp. 13 states: “Stationary wire saw cutting Coconino sandstone.”

(This is the end of the section on “Saws.”)

- “Sculpture in white marble from Carrara 6 axis milling robot sculptures in white Carrara marble statue” (YouTube video)

-

Shot – Harrison Supply Company Catalog, Boston, Massachusetts – For Sawing and Rubbing, Freestone, Granite, Marble and Onyx, Office & Warehouses at No. 34 India Wharf, Boston, Massachusetts, Nathan C. Harrison, General Agent, 1904.

- Slate Channeling by Machinery (November 1891) The Manufacturer and Builder, Vol. 23, Issue 11, November 1891, pg. 254. (Article in digital images viewed at American Memory, Library of Congress.)

- Stone Channeling (April 1894) The Manufacturer and Builder, Vol. 26, Issue 4, April 1894, pg. 86. (Article in digital images viewed at American Memory, Library of Congress.)

- Stone Channeling Machine (The following photograph is from one of the Vermont Marble Company, World’s Largest Marble Exhibit, Proctor, Vermont Postcard Folders (pdf) Click on the pdf link in the preceding sentence if you want to see the rest of the postcard photographs in the folder.)

- Stone Dressing Machine (1871) – “Anderson’s Stone Dresser” – Mastodon Stone Dresser in Scientific American, Vol. XXV, No. 15, October 7, 1871, pp. 223 (Patented July 12, 1870, by Mr. A. G. Anderson; patent owned by Rice & Anderson of Quincy, Illinois.)

- Stone Dressing Machine (pneumatic) (1894) – “A Revolution in the Granite Business,” in The Monumental News, October 1894. (According to this article, the firm Chas. H. More & Co. of Barre and Montpelier, Vermont, was among the first to introduce the Pneumatic Stone Dressing Machine, introduced by the American Pneumatic Tool Company of New York.)

- Stone Ornamenting Machine (using diamond saws) (December 1874) The Manufacturer and Builder, Vol. 6, Issue 12, December 1874, pg. 273. (The article includes a sketch of the machine.) (Article in digital images viewed at American Memory, Library of Congress.)

- Stone Quarrying by Machinery (August 1874) (The article contains a sketch of a "Stone-Quarrying Machine.") The Manufacturer and Builder, Vol. 6, Issue 8, August 1874, pgs. 172-173. (Article in digital images viewed at American Memory, Library of Congress.)

- Stone Quarrying by Machinery (October 1884) (This article includes a sketch of "Saunders' Improved Ingersoll Channeling Machine" and another of a "gang of drills.") The Manufacturer and Builder, Vol. 16, Issue 10, October 1884, pg. 226. (Article in digital images viewed at American Memory, Library of Congress.)

-

Stone Quarrying Film filmed in the 1950s in a Vermont quarry, presented on Facebook (open to the public)

- Stone Quarrying Machines at work from Industrie D'amico SRL – Italy (YouTube video)

- Stone Splitter – Hammer with Splitter with Compressed Air (plugs and feathers) (YouTube video)

- Surface Cutting Granite by Machinery (Pneumatic Stone-Dressing Machine) (September 1894) The Manufacturer and Builder, Vol. 26, Issue 9, September 1894, pg. 207. (The article includes a sketch of a "Pneumatic Stone-Dressing Machine in Operation.") (Article in digital images viewed at American Memory, Library of Congress.)

- Surfacer (in 1910) – “Drill Core Problems,” by Professor Alfred C. Lane, of Tufts College (Until recently State Geologist of Michigan), in Mine and Quarry. Vol. IV, No. 3, January 1910, pp. 367-368A.

- Tempering Steel Tools for Stone Work (May 1892) The Manufacturer and Builder, Vol. 24, Issue 5, May 1892, pgs. 110-111. (Article in digital images viewed at American Memory, Library of Congress.)

- The Toolemera Press & the Toolemera Blog, featuring the books, trade catalogs, photographs and ephemera of early tools, trades, crafts, and industries.

- “Tools and Machinery of the Granite

Industry,” by Paul Wood, in The

Chronicle of the Early American Industries Association, Inc.

Part I. Vol. 59, No. 2, June 2006. (“Introduction: This article, the first in a series of four on granite working, deals with granite as a material, an industry, and a product and begins the description of the granite quarrying process.”)

Part II. Vol. 59, No. 3, September 2006. (“Introduction: This article, the second in a series of four on granite working, completes the description of the quarrying process....”)

Part III. Vol. 59, No. 4, December 2006. (“Granite Finishing: A small number of basic finished dimension stones made up the great majority of granite shed production. For gravestones and private....”)

Part IV. Vol. 60, No. 1, March 2007. (“This article is the last in a series of four on the tools and machinery of granite working....”)

- Tools Used in Stone-Cutting (February 1885) The Manufacturer and Builder, Vol. 17, Issue 2, February 1885, pg. 38. (Article in digital images viewed at American Memory, Library of Congress.)

- Tools Used in Stone-Cutting (February 1890) The Manufacturer and Builder, Vol. 22, Issue 2, February 1890, pg. 32. (This article includes a sketch of the tools used) (Article in digital images viewed at American Memory, Library of Congress.)

-

Traction Engine – “A New Principle in Mechanical Locomotion,” in Stone, An Illustrated Magazine Devoted to Stone, Marble, Granite, Slate, Cement, Contracting and Building, Frank W. Hoyt, Publisher, New York, Vol. XXVII, No. 2, December 1903, pp. 141-145.

The article begins:

- Turning marble urn on lathe (The following photograph is from one of the Vermont Marble Company, World’s Largest Marble Exhibit, Proctor, Vermont Postcard Folders (pdf) Click on the pdf link in the preceding sentence if you want to see the rest of the postcard photographs in the folder.)

|

|

|

Front cover of the Harrison Supply Company Catalog, Boston, Massachusetts, 1904 |

“The Pumice Mines” |

“Our Pumice Warehouse” |

|

|

“Interior Drying Room, Florida” |

“One of our teams loaded with five tons of chilled steel shot, part of shipment just received by steamer from abroad.” |

“Owing to the immense variety of our stone deposits, and their wide distribution, it is generally found that it does not pay to work a quarry unless it is close to railroad transportation. A large proportion of our quarries have switches running from the main track of a railroad directly to the pit whence the stone is taken, so that the output can be loaded directly into the cars with the minimum of handling and expense. Occasionally it is found, however, that certain quarries will pay for operation when there are few facilities for transportation. There may be anywhere from one to ten miles that the stone has to be hauled before a shipping point is reached. This cuts very deep into the margin of profit. One granite quarry in the South that occurs to mind gets out a high grade of monumental stock. This has to be hauled six miles to a railroad, and formerly mule teams were used for the purpose. The company has recently installed a traction engine with excellent results….”

- "Water Also Quarries Stone," Stone World, Anon., Vol. 8, No. 5, p. 47, 1991a. "Where Fine Whetstones Come From" (March 1892) The Manufacturer and Builder, Vol. 24, Issue 3, March 1892, pg. 63. (Text of article in digital images viewed at American Memory, Library of Congress)

- Wire Tramways for General Transportation (February 1885) (The article includes sketches: "The Hodgson System of Traveling Rope," "Loading end, showing terminal rail," "View of Incline Adaptation at Aalsund, Norway.") The Manufacturer and Builder, Vol. 17, Issue 2, February 1885, pgs. 36-38. (Article in digital images viewed at American Memory, Library of Congress.)

Commercial use of material within this site is strictly prohibited. It is not to be captured, reworked, and placed inside another web site ©. All rights reserved. Peggy B. and George (Pat) Perazzo (deceased).