Excerpts from

“The Clay, Stone, Lime and Sand Industries of St. Louis City and County”*

By G. E. Ladd, Assistant Geologist

In Geological Survey of Missouri, Bulletin No. 3, Supplement

December 1890.

Location and product.

“Pickel, Conrad (I, 13): - Mr. Pickel has a quarry which is situated on the northeast corner of Hickory street and Theresa avenue. It was opened in 1883. The product consists of macadam and building stone.

Section.

“The section here is about the same as that at Christian Pieper’s quarry, given below, except that the shale layer changes into shaly limestone.”

Location and product.

“Pieper, Christian (I, 13): - Mr. Pieper has a quarry which is situated on the southeast corner of Carr Lane avenue and Hickory street. It was opened in 1886. The product consists of macadam and building stone.

“The following section, in descending series, was obtained here.: -

Section.

- Loess - 2 feet.

- Limestone, gray, decomposing, in thin beds - 1- feet.

- Limestone, dark gray, soft - 1 foot.

- Limestone, gray, fine grained, compact, in four layers - 4 feet.

- Limestone, dark gray, compact, in three eighteen inch layers - 4 feet, 6 inches.

- Shale - 1 foot, 6 inches.

- Limestone, gray, fine grained, jointed, three layers - 5 feet.

- Limestone, light gray, compact, in two twelve inch, and one thirty-six inch layer - 5 feet.

Total thickness of rock - 31 feet, 6 inches.

Location and product.

“Pendergast, George (D, 7): - Mr. Pendergast has a quarry which is situated on Florence avenue, three or flour blocks north of Easton avenue. It is a small shallow quarry about three hundred feet long by one hundred and twenty-five wide. It was opened in 1889. The product consists of building stone, macadam, dimension stone and riprap.

“The following section, in descending series, was obtained here:-

Section.

- Loess - 4-6 feet.

- Drift - 6 inches.

- Limestone, decomposing - 5 feet.

- Limestone, drab, lithographic - 5 inches.

- Limestone, brownish, numerous crystals of calcite - 8 inches.

- Limestone, gray, fine grained, on weathering exposes many crinoid stems - 2 feet.

- Limestone, light and dark gray, uniform texture - 1 foot, 10 inches.

- Limestone, light gray and brown, numerous calcite crystals and corals, fine grained - 4 feet, 10 inches.

- Limestone, gray and brown, fine grained, siliceous - 1 foot, 3 inches.

- Limestone, light gray, finely crystalline - 2 feet.

Total thickness of rock - 17 feet, 0 inches.

“The beds here dip southeasterly.”

Location and product.

“Ridemeyer (L, 7): - Mr. Ridemeyer has a quarry which is about at Newhouse avenue and Nineteenth street. The quarry is about seventy-five feet square and forty-four feet deep. The product consists of rubble and macadam.

“Following is the section here, in descending series: -

Section.

- Loess - 30 feet.

- Limestone, irregular thin layers - 5 feet.

- Limestone, gray, coarsely crystalline - 2 feet, 6 inches.

- Limestone, gray, coarse grained - 2 feet, 6 inches.

- Shale - 6-10 inches.

- Limestone, gray, compact - 2 feet, 6 inches.

- Limestone, irregular thin layers - 15 feet.

Total thickness of rock - 28 feet, 2 inches.

Location.

“Stiefel and Ruckert, First Quarry (G, 6): - This quarry is situated between Cora and Marcus avenues, on the north side of the Natural Bridge road. Stone for all common purposes is quarried. It was opened in 1888. It is three hundred feet long, sixty-four feet wide, and exposes the following columnar section, in descending series: -

Section.

- Loess - 14 feet.

- Residuary clay mixed with the gravel of the drift - 1 foot.

- Limestone, partially decomposed - 1 foot.

- Limestone, brown, coarse grained - 2 feet.

- Limestone, drab, fine grained, compact, hard and brittle - 9 inches.

- Limestone, gray, coarse grain - 3 inches.

- Limestone, light drab, fine and coarse grained, lithographic in places - 6 feet.

- Limestone, bluish, fine grained - 2 feet, 6 inches.

- Shale, bluish and green, hard, merges into number 8 - 2-7 inches.

- Limestone, dark brown to drab, contains numerous crystals of pyrites - 8 inches.

- Shale, bluish green, in layers, with thin layers of limestone - 1 foot.

- Limestone, very dark gray, coarse grained, quite large masses of pyrites - 11 inches.

- Limestone, dark gray, fine grained, suture joints, fossiliferous, pyrites especially near top - 5 feet.

- Limestone, light gray, fine grained - 3 feet, 8 inches.

- Limestone, gray, coarse grained - 2 feet.

Total thickness of rock - 26 feet, 2 inches.

Location - Plant.

“Stiefel and Ruckert, Second Quarry (M, 15): - This quarry is situated in the city at the foot of Barton street, on the north side of the Iron Mountain and Southern Railway. It is one of the largest quarries in the city, being very deep and having a large rock face to be worked. Its shape is somewhat oval. A view of the south end of the quarry is illustrated opposite page 42 (below). It was opened in 1863. At present its chief product is macadam. Two Rand drills and a No. 4 Gates’ crusher are in use.

| Stiefel and Ruckerts Quarry - Looking South. Illustrating a large and deep sunken quarry in distinction to a bluff quarry. |  |

“The following section,* in descending series, shows the character of the beds: -

Section.

- Loess, the stripping of this quarry - 4 feet.

- Limestone, much jointed and weathered - 20 feet.

- Limestone, (Analysis No. 1), light gray, coarse grained, stylolites at bottom - 2 feet, 5 inches.

- Limestone, (Analysis No. 2), gray and drab, finer grained, splits into layers, lower third lithographic in character, fossiliferous - 3 feet, 11 inches.

- Limestone, (Analysis No. 3), gray, fine grained, highly fossiliferous - 3 feet, 10 inches.

- Limestone, (Analysis No. 4), gray, much jointed, granular, 1 foot, 4 inches.

- Limestone, (Analysis No. 5), soft drab, lithographic, brittle, conchoidal fracture - 1 foot, 3 inches.

- Limestone, (Analysis No. 6), gray to brownish, coarse, granular, stylolites - 4 feet, 7 inches.

- Limestone, (Analysis No. 7), same as No. 8, but variable in grain, few fossils - 2 feet, 3 inches.

- Limestone, (Analysis No. 8), soft drab to brownish, irregularly bedded, brittle, conchoidal fracture - 3 feet, 2 inches.

- Clay shale, soft greenish - 3 inches.

- Limestone, (Analysis No. 9), almost white, fine grained, conchoidal fracture, decomposes readily - 10 inches.

- Limestone, (Analysis No. 10), soft drab and brownish, irregularly bedded, fine grained, conchoidal fracture - 4 feet, 3 inches.

- Limestone, (Analysis No. 11), soft drab and brownish, fine grained, conchoidal fracture - 4 feet, 6 inches.

- Limestone, (Analysis No. 12, almost white, irregularly bedded, brittle, conchoidal fracture, stylolites - 1 foot, 8 inches.

- Limestone, (Analysis No. 13), like number 15, but slightly darker - 3 feet, 3 inches.

- Clay shale, greenish - 2 inches.

- Limestone, (Analysis No. 14), gray to drab, fine wavy bedding lines, fine grained, stylolites - 10 inches.

- Limestone, (Analysis No. 15), light drab, brittle, conchoidal fracture - 1 foot, 10 inches.

- Limestone, (Analysis No. 16), light brown, many bedded, lithographic, cross bedded in places - 4 feet, 5 inches.

- Limestone, (Analysis No. 17), drab, coarse grained, granular stylolites - 2 feet, 9 inches.

- Limestone, (Analysis No. 18), same as No. 21, but finer grained - 1 foot, 10 inches.

- Limestone, (Analysis No. 19), two or more beds, dark gray easily dressed - 6 feet.

Total thickness of rock - 75 feet, 5 inches.

(* For analyses of average samples of the stone from the respective beds of this section, see page 76 (below).)

Location.

“St. Louis Stone Masons Quarry (I, 13): - This is a small quarry situated on the north-east corner of Carr Lane avenue and Hickory street.

“The following section, in descending series, was obtained here: -

Section.

- Loess - 3 feet.

- Limestone, thin weathered layers - 12 inches.

- Shale - 1 foot.

- Limestone, gray, compact - 7 feet.

- Limestone, light gray, compact, in two twelve inch layers - 2 feet.

- Limestone, light gray, crystalline - 5 feet.

- Limestone, thin shaly layers - 8 feet.

Total thickness of rock - 35 feet, 0 inches.

Location and section.

“Watson Construction Company (H, 13): - This firm has a quarry which is situated on the south-west corner of Grand and Chouteau avenues. It was opened in December, 1889. The section here is the same as that given of the Fruin, Bambrick and Company’s third Quarry, p. 50.

Location and product.

“Wieman, William (G-6): - Mr. Wieman’s quarry is situated on the south-west corner of Cora and Margaretta avenues. The product is mostly building stone and macadam. The quarry was opened in 1880. It is sixty feet long, thirty feet wide and exposes the following columnar section, in descending series: -

Section.

- Loess - 5-30 feet.

- Residuary clay and decomposing limestone - 5 feet.

- Limestone, light gray - 4 inches.

- Limestone and chert in thin alternating layers - 1 foot, 6 inches.

- Limestone, light gray - 4 feet.

Total thickness of rock - 5 feet, 10 inches.

Location.

“Work House Quarry (K, 19): - This quarry is situated at the foot of Meramec street, on the Iron Mountain and Southern railway. It has been opened about forty years. The most important product is macadam. The laborers employed are all convicts. The quarry is deep, large and somewhat oval in shape. The following section,* in descending series, shows the character of the beds:

Section.

- Loess as stripping - 5-20 feet.

- Limestone, (Analysis No. 43), in broken and weathered beds - 6 feet, 6 inches.

- Limestone, (Analysis No. 44), dark drab, fine grained - 2 feet, 9 inches.

- Limestone, (Analysis No. 45), light drab, fine grained, two inch layer of chert near top - 2 feet, 4 inches.

- Limestone, (Analysis No. 46), drab and yellowish, fine grained grades in places to No. 4 without separation - 1 foot, 3 inches.

- Limestone, (Analysis No. 47), cross bedded, alternating layers of chert and limestone - 6 feet, 6 inches.

- Limestone, (Analysis No. 48), gray and brown, rather fine grained, several beds of limestone from two to twelve inches thick, two layers of chert two to six inches thick - 3 feet, 10 inches.

- Limestone, (Analysis No. 49), gray, brown and drab, coarse grained - 4 feet, 2 inches.

- Limestone, (Analysis No. 50), gray, fine grained, laminated, four to five beds from one to six inches thick - 2 feet.

- Limestone, (Analysis No. 51), lavender, lithographic, hard, brittle, conchoidal fracture, very fine grained - 1 foot, 4 inches.

- Limestone, (Analysis No. 52), very dark gray, rather fine grained, slightly cross bedded - 1 foot.

- Limestone, (Analysis No. 53), same as No. 11 - 3 feet, 9 inches.

- Limestone, (Analysis No. 54), gray and drab, fine grained hard, carries oblong and spherical masses of chert - 2 feet, 4 inches.

- Limestone, (Analysis No. 55), and chert in alternate but non-continuous layers - 12 feet.

- Limestone, (Analysis No. 56), dark gray, considerable chert - 3 feet, 6 inches.

- Limestone, (Analysis No. 57), dark and light gray, overlaid by two feet of cert with little limestone, laminated, cross bedded - 3 feet.

- Shale - 1 inch.

- Limestone, (Analysis No. 58), gray, drab and greenish, coarse grained, stylolites, fossiliferous, chert band at top - 2 feet, 3 inches.

- Shale - ½ inch.

- Limestone, (Analysis No. 59), light yellow, drab and gray, large balls of chert a foot or more in diameter near top, fossiliferous and geodal - 6 feet.

- Limestone, (Analysis No. 60), gray to brown, line of chert at top, stylolites, soft, fine and coarse grained - 4 feet, 9 inches.

Total thickness of rock - 69 feet, 4 ½ inches.

(* For analyses of the stone from the respective beds of this section see page 77 - below.)

Location - product.

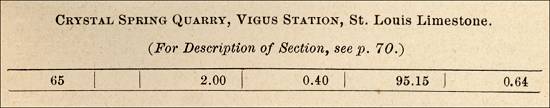

“Crystal Spring Quarry Co. (47): - This firm quarries stone, which is probably of the St. Louis Limestone, in an old bluff of the Missouri river, near Vigus Station, on the St. Louis, Kansas City, and Colorado railway. Work was begun in 1889. The product consists of building stone, riprap, etc., but is soon to include dimension stone which the company intends to produce on a large scale. The quarry is connected with the railway by a switch about one half of a mile long. The company controls several hundred yards face of workable stone. There are three openings in the bluff from each of which stone is removed by the use of derricks to freight cars on which it is shipped.

Section.

“The section here is the same as given below for the quarry of the Watson Construction Co., which is close at hand. A sample for analysis was collected here from beds numbers 4 to 10 (inclusive) of this section.

Location.

“Doering, J. H. (51): - Mr. Doering has a quarry situated on the Carondelet Branch railway, southwest of Bobring, in the St. Louis Limestone. It is connected with the railway by a half mile switch. The quarry has a workable face about eight hundred feet long. The product consists of dimension stone, macadam and riprap.

Location and product.

“Eureka Quarry Co. (57): - This company has a quarry which is situated on the Gravois road about an eighth of a mile northeast of Afton, in the St. Louis Limestone. Work was begun in 1889. The product consist of building stone and macadam.

“The following section, in descending series, was obtained here: -

Section.

- Stripping, residuary clay and decomposing limestone - 5 feet.

- Limestone, lavender, lithographic - 1 foot, 1 inch.

- Limestone, gray, crystalline - 1 foot, 10 inches.

- Limestone, same as last but fossiliferous - 2 feet.

- Limestone, light gray, crystalline, calcite veins, fossiliferous, in several layers - 3 feet.

- Limestone, light gray, crystalline, in four layers - 3 feet, 6 inches.

- Limestone, gray, coarse grained, crystalline, calcite, in thin layers - 2 feet, 3 inches.

- Limestone, gray, fine grained, crystalline - 6+ inches.

Total thickness of rock - 14 feet, 2 inches.

Location.

“Fabrick, Philip, and Marshall (53): - This firm has a quarry situated about one-fourth of a mile west of the Doering and Munsen quarries, and about three hundred yards from the Carondelet Branch railway. This stone quarried belongs to the St. Louis Limestone.

“The following section, in descending series, was obtained here: -

Section.

- Soil and residuary clay - 6 feet.

- Limestone, partially decomposed - 5 feet.

- Limestone, dark gray, fine grained - 1 foot, 6 inches.

- Limestone, gray to brown, coarse grained, soft - 3 feet.

- Limestone, dark gray, coarse grained - 1 foot, 10 inches.

- Limestone, gray to brown, vary grained - 1 foot, 8 inches.

- Limestone, dark gray, lithographic, in three layers - 2 feet, 6 inches.

- Limestone, buff, shaly and soft - 1 foot, 8 inches.

- Limestone, dark drab, lithographic - 1 foot, 9 inches.

- Limestone, very dark drab, fine grained, crystalline, calcite veins, two layers separated by a thin bed of brown shale - 2 feet, 10 inches.

- Limestone, dark gray, lithographic, in three layers - 2 feet, 4 inches.

- Limestone and shale, in three alternating layers - 3-6 inches.

- Limestone, dark gray to lavender, fine grained - 1 foot, 2 inches.

Total thickness of rock - 25 feet, 8 inches.

Location and product.

“Glendale Quarry Co. (55): - This company has a quarry on the Carondelet Branch railway about half way between Kirkwood and Webster, in the St. Louis Limestone. It was opened in 1889. The product consists mostly of dimension and building stone. The quarry has a workable face of about three hundred feet and operates two channeling machines.

“The following section, in descending series, was obtained here: -

Section.

- Stripping, clay and decomposing limestone - 6 feet.

- Limestone, yellow to lavender, lithographic, concretions in places (has been used by lithographers) - 2 feet, 6 inches.

- Limestone, dark gray, soft - 1 foot, 6 inches.

- Limestone, almost white, soft, weathers into two layers -2 feet, 10 inches.

- Limestone, dark gray, coarse grained, crystalline - 2 feet.

- Limestone, dark gray, fine grained, in two layers - 2 feet, 2 inches.

- Limestone, dark gray, fine grained, chert concretions occasionally - 4 feet.

- Limestone, mottled gray to brown, coarse grained, crystalline - 1 foot.

- Limestone, brownish gray, soft, in two layers of equal thickness - 4 feet.

- Limestone, gray, coarse grained - 2 feet.

Total thickness of rock - 22 feet, 0 inches.

Location and product.

“Lauritzen, James (56): - Mr. Lauritzen’s quarry is situated at Webster. The product consists of building and dimension stone, and macadam. The quarry is in the St. Louis Limestone.

“The following section, in descending series, was obtained here: -

Section.

- Stripping, soil, residuary clay and decomposing limestone - 5 feet.

- Limestone, almost white, fine grained, crystalline, conspicuously cross bedded - 5 feet.

- Limestone, dark gray, coarse grained, suture joints, chert concretions, in numerous layers - 2 feet, 6 inches.

- Limestone, drab, lithographic, in eight layers - 3 feet, 9 inches.

- Limestone, chocolate to gray, fine grained, fossiliferous - 9 inches.

- Limestone, lavender, fine grained, chert concretions - 1 foot.

- Limestone, lavender, fine grained, fossiliferous, in four layers - 2 feet.

- Limestone, varying in color and texture, in layers one or two inches thick - 3 feet.

- Limestone, lavender, fine grained, in layers from six to eight inches thick - 2 feet, 6 inches.

Total thickness of rock - 20 feet, 6 inches.

Location and product.

“Munsen (52): - Mr. Munsen has a quarry in the immediate neighborhood of Mr. Doering’s, with the same railway connection. The product consists of ‘furnace rock.’ The quarry was opened in 1880. Its face is about seven hundred and fifty feet long. The stone quarried is of St. Louis Limestone.

“The following section, in descending series, was obtained: -

Section.

- Soil and residuary clay - 5 feet.

- Limestone, decomposing - 12 feet.

- Limestone, gray, fossiliferous, in several layers - 5 feet, 10 inches.

- Limestone, buff, alternately fine and coarse grained, soft, fossiliferous - 3 feet.

- Limestone, gray, crystalline - 1 foot, 10 inches.

- Limestone, blue to yellowish, vary grained - 3 feet, 9 inches.

- Limestone, gray, coarse grained, fossiliferous, in two layers - 1 foot, 4 inches.

- Limestone, gray, fine grained - 9 inches.

- Limestone, gray, crystalline, fossiliferous, in three layers - 10 inches.

- Limestone, gray, fine grained, brittle, fossiliferous, small chert concretions near middle - 4 feet, 10 inches.

- Limestone and shale in thin layers - 8 inches.

- Limestone, gray, fine grained, numerous small concretions of chert - 1 foot, 6 inches.

- Limestone, light gray, hard, siliceous - 7 inches.

- Limestone, light gray, soft - 1 foot, 4 inches.

- Limestone, dark gray, lithographic - 8 inches.

- Limestone and shale - 8 inches.

- Limestone, grayish to brown, coarse grained, crystalline, three layers - 3 feet, 5 inches.

- Limestone, lavender, fine grained, brittle - 1 foot, 1 inch.

- Limestone in thin layers, with shale partings, gray to lavender, fine grained - 10 inches.

- Limestone, dark gray, concretionary, in three layers - 2 feet, 9 inches.

- Limestone, light lavender, fine grained, hard and brittle - ---

- Limestone, suture joints - 3 inches.

- Limestone, light lavender, fine grained, hard and brittle, in three layers, respectively thirty, twenty-four and eight inches thick - 4 feet, 6 inches.

Total thickness of rock - 52 feet, 5 inches.

Location and product.

“Shores Quarry Co. (54): - This quarry is situated on the Kirkwood Branch railway, five miles from Carondelet, in the St. Louis Limestone. It was opened March, 1889. The product consists of ‘furnace rock,’ paving, building and dimension stone. the quarry is an open cut in a hill-side.

“The following section, in descending series, was obtained here: -

Section.

- Soil and residuary clay - 4 feet.

- Limestone, decomposing - 2 feet.

- Limestone, gray to brown, coarse grained - 3 feet, 9 inches.

- Limestone, lavender, lithographic, in three layers, the two lower of which are separated by a thin layer of shale - 3 feet, 2 inches.

- Limestone, gray, coarse grained, crystalline - 1 foot, 2 inches.

- Limestone, lavender, lithographic, in four layers - 8 feet.

- Limestone, gray, fine grained, chert concretions, several layers - 4 feet.

- Limestone, brownish, siliceous, chert concretions, several layers - 1 feet. 6 inches.

- Limestone, gray, crystalline, almost a solid mass of fossils - 1 foot, 4 inches.

- Limestone, brownish to gray, coarse grained - 1 foot, 8 inches.

- Limestone, dark lavender, numerous chert concretions - 10 inches.

- Limestone, light gray, lithographic, chert concretions - 1 foot, 8 inches.

- Limestone, lavender, lithographic, calcite veins - 1 foot, 3 inches.

- Limestone, dark gray, rather coarse grained - 1 foot.

- Limestone, mottled, vary grained, concretionary - 2 feet, 3 inches.

- Limestone, gray, crystalline, fine grained toward bottom - 3 feet, 7 inches.

- Limestone, lavender, lithographic, in three layers - 1 foot, 8 inches.

- Limestone, yellow, shaly - 1 foot, 6 inches.

- Limestone, lavender, lithographic - 1 foot, 1 inch.

- Limestone, gray, fine grained, soft - 1 foot, 2 inches.

- Limestone, light gray, fine grained, weathers white - 2 feet, 2 inches.

- Limestone, drab and pinkish, lithographic - 1 foot, 8 inches.

Total thickness of rock - 46 feet, 5 inches.

Location and product.

“Theby, Michael (48): - Mr. Theby has a quarry which is situated on the west of South Broadway, near the river Des Peres, in the St. Louis Limestone. The product consists mostly of ‘furnace rock,’ which is sold to iron furnaces for fluxing purposes; but a small amount is used as macadam, building stone, and dimension stone. The quarry is in a bluff, and has about one hundred yards of workable face. No machinery is used.

“The following section in descending series was obtained here: -

Section.

- Loess and residuary clay - 16 feet.

- Limestone, much decomposed - 4 feet.

- Limestone, drab, coarsely crystalline in two layers of equal thickness - 4 feet, 8 inches.

- Limestone, grayish, coarsely crystalline in three layers - 1 foot, 10 inches.

- Limestone, gray, drab, compact, brittle, splintery fracture suture joints, fossiliferous, in two layers - 3 feet, 3 inches.

- Limestone, buff to bluish, in beds two to six inches thick - 3 feet.

- Limestone, lavender, lithographic - 1 foot.

- Limestone, lavender, grading to buff towards the bottom, harder and finer grained towards the top - 2 feet, 1 inch.

- Limestone, buff, rather fine grained, calcite veins, in layers varying from three to eighteen inches in thickness - 5 feet.

- Limestone, mottled buff and bluish, blotches of calcite, very fossiliferous - 3 inches.

- Limestone, mottled buff and bluish, blotches of calcite, suture joints - 2 feet, 8 inches.

- Limestone, lavender, compact, siliceous - 1 foot, 6 inches.

Total thickness of rock - 29 feet, 3 inches.

Location and product.

“Zeiss, Henry (49): - Two quarries belonging respectively to Mrs. James Zeiss and to Henry Zeiss, are at present worked as one quarry. They adjoin each other in the bluff of St. Louis Limestone, in the neighborhood of Mr. Theby’s quarry, mentioned above. There is about two hundred and fifty yards of workable face to the quarry. It was opened in 1872. The product consists of macadam, dimension stone, ‘furnace rock,’ etc.

“The following section, in descending series, was obtained: -

Section.

- Loess - 6 feet.

- Limestone, decomposing, and residuary clay - 10 feet.

- Limestone, lavender, with mottled appearance, vary grained, calcite blotches at bottom, very fossiliferous - 2 feet, 4 inches.

- Limestone corresponding to numbers 3, 4, 5 and 6 of the Theby section as given above - 12 feet, 9 inches.

Total thickness of rock - 25 feet, 1 inch.

Location.

“Watson Construction Company (65): - This company has a quarry which is situated in the bluffs of the Missouri river, at Vigus Station. The stone quarried is probably St. Louis Limestone. The quarry is connected with the St. Louis, Kansa City & Colorado railway. Stone is swung from the quarry by derricks directly to the freight cars. The product is mostly riprap.

“The following section,* in descending series, was obtained here: -

Section.

- Soil and Loess - 9-11 feet.

- Residuary clay - 4-5 feet.

- Limestone, partially decomposed - 4-5 feet.

- Limestone, drab, fine grained, hard, brittle, conchoidal fracture, in thin layers, one to three inches thick - 2 feet, 6 inches.

- Limestone, like No. 4, but coarser grained and has calcite veins - 8 inches.

- Limestone, drab, coarse grained, brittle, sub-conchoidal fracture, suture joints, specked with calcite and chert, occasional chert concretions, quarries as one bed in some places, but in others it splits into two beds - 3 feet, 10 inches.

- Limestone, like No. 6, but contains pyrite crystals - 8 inches.

- Limestone, gray, coarse grained, many calcite blotches - 1 foot, 1 inch.

- Limestone, like No. 8, but in layers three or four inches thick - 2 inches.

- Limestone, gray, coarse grained, specked with calcite, very fossiliferous, often quarries in solid blocks, but in places splits into many beds - 4 feet, 5 inches.

- Limestone, in heavy beds, much weathered, and covered mostly with talus - 10 feet.

Total thickness of rock - 27 feet, 7 inches.

| Statistics of The Stone Quarries of St. Louis City and County For the Year 1889. This list does not include lime producing quarries. |  |

The Lime Industry.

General Remarks.

Formations furnishing lime.

“A large portion of the lime which is consumed and sold in St. Louis is produced in distant portions of the State. There are a number of ‘active’ lime kilns in St. Louis county, but none at present within the city limits. Stone from the St. Louis, Keokuk, Burlington and Trenton formations has (sic) been burned, to some extent, but the Trenton rocks seem to have given the most satisfaction, and are now most extensively used (circa 1890). The Burlington formations, where accessible, furnish perhaps the best quality of limestone, but the limestone beds are so intimately mixed with layers and concretions of chert, that the sorting of the materials has proved too great an expense for the extensive use of these beds.

Analyses of Limestone.

Objects of analyses.

“For the purpose of determining the value of the local materials for the manufacture of cement and lime, a large number of samples of limestone have been analyzed. Wherever a formation is now being quarried for the manufacture of lime, there, samples of stone were collected. The analyses were made with two specific objects in view. The first was a determination of the absolute value of the rock; the second was the establishment of a standard for comparison with the collections from horizons which are not worked for lime production.

No lime kilns in city limits. - Typical section. - Results to be reached.

“The St. Louis Limestone, within the city limits, is not at present used for lime making. Were the fact established that beds of the requisite quality for this purpose existed within these limits, these beds could be used to great advantage, first, because of their proximity to the local market, and, secondly, because great quantities of waste rock at the numerous quarries could be utilized. Hence, for the purpose of collecting a complete series of samples, a section was selected in this formation which should represent as nearly as possible all of the different beds which could be made available. This section of the St. Louis Limestone was constructed from measurements made at three quarries along the Mississippi river. Going south each section is thought to be approximately a continuation of the preceding one. That at the Stiefel and Ruckert quarry represents the higher part of the formation, that at Martin Lorentz’, the next lower, and that at the Work House quarry, the lowest available part. At the outset it was hoped that sufficient analytical work could be done to determine whether the qualities of the various beds were persistent throughout their extent; but, owing to a considerable dip of these beds a much larger section was found than had been anticipated, and, consequently, the number of analyses to be made grew so large as to make this attempt impracticable, at least, for the time being. The results of the analyses can, therefore, be applied with exactness only to those outcrops from which the samples were actually taken; they only suggest what may be expected in other portions of the beds they represent.

“The following conventional cross section, running a little west of south, will illustrate the conditions of occurrence and the interpreted relations of the sections:

| Diagramatic cross section in the St. Louis Limestone, indicating the relative position of the rocks in the quarries where the beds were sampled for analysis. Looking west. |  |

Character of samples.

“The samples for the analyses given in the following tables were collected mostly from active stone quarries. They were taken so as to represent as nearly as possible an average of the beds, vertically and laterally, in the immediate vicinity of the section. In addition to such samples collections were made from different geological formations as follows: -

Keokuk Limestone.

“From the Keokuk Limestone at the second tunnel of the Missouri Pacific railway, the sample for analysis No. 64 was taken as an average of the exposed strata, which amount to about thirty feet in thickness.

Burlington Limestone.

“From the Burlington Limestone near Valley Park, an average sample of the beds was taken for analysis No. 66, at an old quarry which was formerly worked for lime production, and near which an old kiln is still standing (circa 1890). The abundance of chert in the beds has caused the abandonment of work.

First Magnesian Limestone.

“From the heavy beds of the First Magnesian Limestone, near Glencoe, an average sample was taken for analysis No. 77.

Reference numbers.

“In the following tables of analyses reference is made under each title to the page where the section is described from which samples were collected; further the stratum number is given with each analysis number. In the descriptions of sections thus referred to, analyses numbers accompanying the respective strata, again refer back to the tables of analyses.

Analyses of Limestones from St. Louis City and County.

“In the following table of analyses the term ‘insoluble silicious residue’ means that portion of the limestone which is insoluble in dilute Hydric Chloride (1 to 3), exclusive of organic matter. The existence of the latter was recognized in all samples, but was burned off before weighing. These residues consist for the most part, of clear transparent quartz; but, with the higher percentages of ‘insoluble residue,’ some clay and other insoluble matter is presumably present. The term ‘combined oxides’ is meant to include alumina and ferric oxide which were weighed together. The lime and magnesia found by analysis were calculated as carbonates and are so tabulated. The percentages are of samples dried at 100° C. Percentages marked with an asterisk (*) were determined by difference.

A. E. Woodward.

Samples Nos. 1 to 60 inclusive are of successive beds of the St. Louis Limestone, taken in a descending order.

Chas. W. Goetz’ Quarry, St. Louis Limestone.

(Headings: Analysis No.; Stratum No.; Insoluble Siliceous Residue; Combined Oxides; Calcium Carbonate; Magnesium Carbonate;)

Railway Cut, 2d Tunnel, Keokuk Limestone.

(Headings: Analysis No.; Stratum No.; Insoluble Siliceous Residue; Combined Oxides; Calcium Carbonate; Magnesium Carbonate;)

Crystal Spring Quarry, Vigus Station, St. Louis Limestone.

(Headings: Analysis No.; Stratum No. Insoluble; Siliceous Residue; Combined Oxides; Calcium Carbonate; Magnesium Carbonate;)

Railway Cut, Valley Park, Burlington Limestone.

(Headings: Analysis No.; Stratum No.; Insoluble Siliceous Residue; Combined Oxides; Calcium Carbonate; Magnesium Carbonate;)

Herbert Dorenheim’s Quarry, St. Paul, Trenton Limestone.

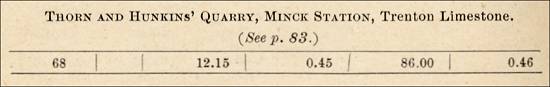

Thorn and Hunkins’ Quarry, Minck Station, Trenton Limestone.

(Headings: Analysis No.; Stratum No.; Insoluble Siliceous Residue; Combined Oxides; Calcium Carbonate; Magnesium Carbonate;)

Glencoe Company’s South Quarry, Glencoe, Trenton Limestone.

(Headings: Analysis No.; Stratum No.; Insoluble Siliceous Residue; Combined Oxides; Calcium Carbonate; Magnesium Carbonate;)

Glencoe Company’s Middle Quarry, Glencoe, Trenton Limestone.

(Headings: Analysis No.; Stratum No.; Insoluble Siliceous Residue; Combined Oxides; Calcium Carbonate; Magnesium Carbonate;)

Railway Cut, Glencoe, First Magnesian Limestone.

(Headings: Analysis No.; Stratum No.; Insoluble Siliceous Residue; Combined Oxides; Calcium Carbonate; Magnesium Carbonate;)

Discussion of analyses.

“While not attempting here an exhaustive discussion of the results contained in the preceding tables, a brief reference will be in place to some of the more salient features developed. An analysis of the contents of these tables results in the following classification: -

Total number of analyses - 77.

Number of samples of stone not at present used for lime production - 65.

Number of samples from St. Louis city - 60.

Number of samples from St. Louis county - 17.

Number of samples from the St. Louis Limestone - 64.

(Three of these are from beds at present used.)

Number of samples from the Keokuk Limestone - 1.

(An average of all the beds exposed.)

Number of samples from the Burlington Limestone - 1.

(An average of the beds formerly used.)

Number of samples from the Trenton Limestone - 10.

(Nine of these are of beds now used.)

Number of samples from the First Magnesian Limestone - 1.

(An average of beds aggregating about 30 ft. in thickness.)

Limestone with 89 percent. of lime.

“The limestones used commercially for the manufacture of lime rarely contain less than eighty-nine per cent. of calcium carbonate. Applying this fact here, we are able to separate those limestones which are probably of value for this purpose, from those which are not, at least so far as the lime contents is concerned. Of the analyses of the twelve beds or series of beds which lime producers are now using there is but one the results of which show the amount of impurity to exceed ten per cent., and in that case the excess is only a fraction of one per cent. To be compared favorably with these twelve, there are of the remaining sixty-five limestone samples, thirty-four in which the amount of calcium carbonate is above eighty-nine per cent. The beds represented by these thirty-four are those of Valley Park and Vigus Station, twelve at the Stiefel and Ruckert quarry, eleven at Martin Lorentz’ quarry, and nine at the Work House quarry.

Distribution of lime beds.

“The beds at Valley Park seem to be rendered useless by the immense amount of chert which they contain. At Vigus Station the six successive beds (which are quarried for building stone) were sampled at the Crystal Spring quarry. They have a total thickness of a little over fifteen feet, and would be available for the manufacture of lime. At the Stiefel & Ruckert quarry the twelve beds, Nos. 5 to 10, 14 to 16 and 21 to 23, have a total thickness of 36 ½ ft., and they occur in one group of six beds, and two groups of three beds each. The total thickness of the group of six beds is 16 ½ ft. At Martin Lorentz’ quarry the eleven beds, Nos. 6, 7, 10, 11, 19 and 21 to 26, have a total thickness of 26 ½ ft., and six of these having a total thickness of 15 ¼ ft. are successive beds. At the Work House quarry the nine beds, Nos. 2, 7, 9, 10, 12, 13, 14, 18, 21 are somewhat separated, but six of them have a total thickness of 25 ¼ ft., and are separated by only two beds, of inferior quality, which have a total thickness of 4 1/6 feet. The total thickness of the nine beds is 39 feet.

Final results postponed.

“The final settlement of the question of the adaptabilities of these limestones is, however, left for future investigation and experiment. Some of the limestones are remarkably pure and are worthy of being experimented with, in connection with some of the neighboring clays, for the production of hydraulic cement.”

A Descriptive List of Lime Works.

“The following descriptions include only the works of producers which are situated within the county or city of St. Louis; some of the firms mentioned have extensive works in other parts of the State.

“Dorenheim, Herbert (76): - Mr. Dorenheim began producing lime with one kiln, at St. Paul, in May, 1890. Since that time he has produced about six thousand bushels per month.

Product.

“The stone, which burns to a black lime, is taken from the quarry of the old firm of Goetz & Cobb, which now has here (owing to some litigation) three idle kilns.

Formation.

“The formation quarried is Trenton Limestone, and the sample for analysis number 67, was taken as an average of the beds used for lime making.

Location.

“Glencoe Lime and Cement Company (70 to 72): - This company has two sets of works at present (circa 1890) operating, which are located respectively about two and four miles north-west of Glencoe. Both are connected with the main line of the Missouri Pacific railway by a branch track.

Character of product.

“Two kinds of lime, known as white and black lime, are produced. The former is a finishing lime and commands a high price, but has a comparatively small sale. The latter is used for many purposes, and constitutes the bulk of the product, selling at a much lower price than the white lime. The two varieties differ very much in character; the black lime being said to slack slowly and coolly, and to set rapidly, while the white lime acts in an opposite way.

Trenton stone. - Product.

“All of the limestone used at both places comes from the Trenton formation. At the works nearest Glencoe there are two quarries and two kilns.* One of the quarries, which we term the southern one, furnishes a stone which burns to a white lime.

(*Page 81 footnote: Some of the beds here will furnish a good dimension stone, while some that would appear to do so are worthless for that purpose because of their tendency to weather into a honey-comb condition, as previously described.)

“Following is a section at this quarry in descending series. Analysis No. 69 is of an average sample of all the beds: -

Section.

- Slope of stripping - ---

- Limestone, gray to lavender, fossiliferous, vary-grained, vermiform cavities, very cherty - 5 feet.

- Like No. 2, but more cavities - 3 feet, 9 inches.

- Limestone, brown, very cherty, coarse grained, fossiliferous, vermiform cavities - 3 feet.

- Limestone, brown to gray, granular - 2-4 inches.

- Limestone, thin beds, gray to lavender, fossiliferous, coarse grained vermiform cavities - 3 feet.

- Like No. 6, but finer grained - 4 inches.

- Like No. 6, but vary-grained - 4 feet, 4 inches.

- Limestone, brown, granular, fossiliferous - 2 inches.

- Slaty shale, fossiliferous - ¼ - ½ inch.

- Limestone, lavender, vary grained, fine to very coarse - 8 inches.

- Shale - ½ inch.

- Limestone, gray and brown, vermiform structure in grain, very fossiliferous - 2 feet, 1 inch.

- Same as No. 13, but less fossiliferous - 3 feet.

Total thickness of rock - 26 feet, 8 inches.

Product.

“About an eighth of a mile north of this quarry a new quarry has been recently opened, from which a stone is taken which burns to a black lime. The opening is not yet sufficiently developed to expose a good section. The rock is very fossiliferous, semi-crystalline, and colored light and dark gray. An average sample of this rock was used for analysis No. 70.

“At the works, about four miles north-east of Glencoe, are the two ‘north’ quarries and three kilns. The quarries are higher stratigraphically and topographically than those described above. The stone taken from them burns to a black lime.

“The following section, in descending series, was made at these quarries. Numbers 4, 5 and 6 are but imperfectly separated.

Section.

- Slope of stripping - ---

- Limestone, (analysis No. 71), decomposing and clayey - 3 feet.

- Limestone, (analysis No. 72), gray turning to almost black towards top, irregular chert layer, sub-crystalline, fine grained, hard, fossiliferous - 1 foot, 2 inches.

- Limestone, (analysis No. 73), bluish, mostly fine grained but coarse in patches, sub-crystalline, calcite blotches, hard, suture joints, splintery fracture - 1 foot, 1 inch.

- Limestone, (analysis No. 74), gray, soft at base but harder toward top, fine grained - 7 feet, 4 inches.

- Limestone, (analysis No. 75), light gray, highly fossiliferous, semi-crystalline, coarse grained, irregular fracture, suture joints, cherty in places - 6 feet, 9 inches.

- Limestone, (analysis No. 76), dark gray, ferruginous bands, extremely fossiliferous, soft, granular, coarse grained - 7 feet.

Total thickness of rock - 26 feet, 4 inches.

Mode of quarrying.

“In each of these quarries the rock is dislodged from the face of the quarry, and more or less shattered by powder blasts. It is then broken into quite small pieces by the use of hammers, and hauled in carts up an inclined plane, whence it is dumped into the kilns to be burned. After the burning it is shoveled directly into freight cars.

Product.

“Goetz, Charles W. (73 and 75): Mr. Goetz has lime works at Bartholds valley, and at a point on the county line near Port Royal. At the former place there are two kilns and three quarries, only one of which is, however, at present worked (circa 1890). A high grade of white finishing lime is produced. The section here, presumably in St. Louis Limestone, is as follows, in descending series: -

Section.

- Stripping - 10 feet.

- Limestone, (analysis 61), dark gray, fine grained, hard - 4 feet, 8 inches.

- Limestone, (analysis No. 62), light gray, fine grained, soft, fossiliferous - 3 feet.

- Limestone, (analysis No. 63). Like No. 3 but harder - 5 feet.

Total thickness of rock - 12 feet, 8 inches.

“The works at Port Royal have been only recently started. Stone from the Trenton horizon is to be used, and two kilns are in the process of construction (circa 1890).

Location.

“Thorn and Hawkins (74): - This firm has its works located at Minck, on the ‘Frisco’ railroad, just across the Meramec river from St. Paul. One kiln is (sic) use, and stone is procured from two quarries, in the Trenton Limestone, which are situated at different elevations in an old bluff of the river. The formation is characteristically Trenton. The sample for analysis No. 68 was taken as an average of the beds here quarried which represent a total thickness of about thirty feet.

Statistical Tables.

“The facts given in the following table are the results of personal inquiry of the proprietors of the works. The production of lime in the vicinity of St. Louis has much increased since 1889, and the totals given below will probably fall far short of the figures for the present year.”

The Sand and Gravel Industry.

General Remarks.

Source of sand and gravel.

“The great mass of sand and gravel which is consumed in St. Louis comes from the Meramec river. A smaller amount is taken from the Mississippi river, and, comparatively, a very little from gravel deposits in the northern part of the city, which seem to belong, geologically, to the assorted drift of the glacial period. Red and gray gravel are shipped to St. Louis from Robertsville and other points in Franklin county.

“The sand from the Meramec river is superior in quality to that from the Mississippi, which contains black, probably carbonaceous particles, which are said to ‘pop’ in pointing. It is rather coarse and the grains are somewhat rounded.

A Descriptive List of Sand and Gravel Works.

“St. Louis Dredging Co.: - This company was organized in 1883, with a capital stock of $50,000. It furnishes all the sand and gravel to the following companies, viz.: Griffith & Adams Sand and Gravel Transit Co., The New Missouri Sand Co., New St. Louis Sand Co., and the Eagle Sand Co.

“In 1889 it sold 117,048 loads of sand and gravel, at an average price of 60 cents per load at the boat. A few barges full have been taken to the Illinois side.

“The Eagle Sand Co.: - Previous to March this company did its own dredging. In 1889 it sold about 6,000 loads.

“The Griffith & Adams Co.: - This company was organized in 1874, with a capital stock of $12,000. Its sand is obtained from the area in the Mississippi river between the Eads and Merchants bridges.”

Commercial use of material within this site is strictly prohibited. It is not to be captured, reworked, and placed inside another web site ©. All rights reserved. Peggy B. and George (Pat) Perazzo.