Sandstone Industry in the Various States.

Alabama. -Sandstone has been produced from quarries in Jefferson, Colbert, and St. Clair counties. Production in 1894 has been much restricted, but indications for improvement in 1895 are well defined and unmistakable.

Arkansas. -But very little sandstone is quarried in Arkansas, although it has been produced on a limited scale in four different counties, namely, Johnson, Sebastian, Conway, and Miller.

California. -In sandstone production, as in that of all other kinds of stone, the year 1894 has been an exceedingly dull one in this State. Production in 1894 was so limited as to be hardly worth noting. In former years sandstone has been produced, as in the following counties named in order of importance: Santa Clara, Amador, Ventura, San Bernardino, Yolo, Solano, and Napa.

Colorado. -Production of sandstone in Colorado a few years ago had assumed quite large proportions, and in 1889 the value of the output was found to be $1,224,098. During 1894 the industry almost came to a standstill, many operators quitting the business entirely, while others barely existed in their struggles with slack demand, low prices, and slow conditions. The counties which have yielded sandstone are, in order of importance: Boulder, El Paso, Larimer, Eagle, Jefferson, Las Animas, Fremont, Park, Huerfano, and Montezuma.

Connecticut. -Practically the entire output of sandstone in this State comes from the well known quarries at Portland, Middletown, and Crowell, in Middlesex County. The product of these localities has long been in favor in the most important cities of the East. While production is in amount well below that of a few years since, the industry is in a stable condition, with promise of decidedly better results in 1895.

Georgia. -While a small quantity of sandstone was produced in 1894, this branch of the stone industry in Georgia has never amounted to a great deal. Much more enterprise has been shown in the development of its valuable resources in granite, marble and slate.

Idaho. -The output of sandstone in Idaho exceeded that of the census year, but the industry does not yet cut much of a figure. The produce is confined to Ada County.

Illinois. -This State, while very prominent for its limestone output, has not as yet done much in the way of quarrying sandstone, although operations have been carried on in Henry Fulton, Whiteside, Union, Knox, Lee, and Clay counties.

Indiana. -Indiana is widely known for oolitic limestone rather than for other varieties. Sandstone is produced to a limited extent in the following counties: Warren, Fountain, Orange, and Putnam.

The sandstone of Orange County deserves especial mention on account of its value for abrasive purposes. This stone is said to need no oil to soften it, but is used with water alone, and it appears to be very popular for the purpose of sharpening tools. It has been very highly recommended for razor hones and for sharpening axes ad knives. It is found chiefly in the western part of Orange County, and appears to be produced in no other county of the State. Much of it is shipped in the rough to various points in New York to be sawed.

Iowa. -Sandstone production has been at quite a low ebb in 1894, although it has never been of much importance to the State. Marion and Hardin counties have been the most important, though small amounts have been quarried in Cerro Gordo, Clayton, Lee, Jasper, Washington, and Scott counties.

Kansas. -Sandstone is found in all parts of this State, but the most productive portions are in the southern and southeastern counties. Bourbon, Phillips, and Rawlins counties are the most productive, although quarries have been operated in Crawford, Woodson, Clark, Wilson, Kingman, Harper, and Comanche counties.

But little was done in 1894.

Kentucky. -Although sandstone has been quarried in seven counties of the State, almost nothing was done in 1894. Productive counties are Rowan, Muhlenberg, Lewis, Bell, Crittenden, Rockcastle, and Ohio.

Maryland. -The annual production of sandstone in this State has never been large, although some of the stone is fine in quality. This statement applies particularly to stone quarried in Montgomery County, on the Potomac River, 20 miles from Washington. It was known originally as Seneca red sandstone. It has been used in quite a large number of buildings in the city of Washington, notably the Smithsonian Institution. From all the evidence which has been submitted it appears to be one of the best red sandstones in the country. Many of the strong and unqualified indorsements of this stone appear as the favorable result of an investigation of a committee of Congress appointed to investigate the use of this stone in the construction of the State, War, and Navy Department building in Washington.

Michigan. -This State has produced some fine grades of sandstone, which are favorably received by builders over quite a wide area of the country. Leading producers report poor business for the past year, but there is no doubt that indications for 1895 are much more favorable.

Minnesota. -Production fell off markedly in 1894. Productive counties are Pine, Pipestone, St. Louis, Houston, Rock, and Scott.

The developments which have been made in Pipestone County in what is commercially known as "Pipestone red jasper" are of particular interest. This is a metamorphic quartzite rock of intense hardness varying in color from cherry to lavender or violet. Its extreme hardness is another important characteristic. The following analysis was made by Dr. C. T. Jackson

|

Analysis of red pipestone from Pipestone County, Minn. |

|

|

|

Percent |

| Water | 8.4 |

| Silica | 48.2 |

| Alumina | 28.2 |

| Magnesia | 6 |

| Peroxide of iron | 5 |

| Oxide of maganese | .6 |

| Carbonate of lime | 2.6 |

| Loss | 1 |

| Total | 100.0 |

The following tests of this stone have been made:

|

Tests of Minnesota red pipestone |

|

|

Crushing strength |

lbs. Per sq. in. 23,000 |

|

Specific gravity |

2.8 |

|

Weight per cubic foot |

lbs. 170.6 |

On account of its color and desirable properties which tend to make the stone durable, it is quite popular as a building material, and has already been used in the construction of a large number of important buildings.

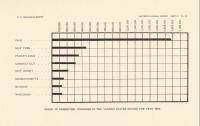

Missouri. -Sandstone quarrying was very much depressed throughout the year. In spite of hard times, however, the falling off was not nearly so pronounced as in many other States. The value of the product in 1889 was $155,557, and in 1894, $131,687. The most important counties are Johnson, St. Clair, and Cape Girardeau; others less productive are Carroll, Barton, Saline, Franklin, Vernon, Holt, Lewis, Buchanan, and Henry.

New Jersey. -The sandstone industry of New Jersey is one of considerable magnitude, having amounted in 1889 to a valuation of $597,309. The decrease to $217,941 in 1894 appears to be entirely attributable to the general low condition of trade.

New York. -The sandstones of this State are quire various in color and in fineness of texture; some of them have won lasting reputations for adaptability to building purposes. Production languished in 1894, amounting in value to $450,992, while in 1889, the corresponding figure was $702,419.

The best known sandstone is the Potsdam red sandstone. It has an enviable reputation for durability and for ability to withstand the effects of sudden heating and cooling.

The leading counties producing sandstone are Orleans and St. Lawrence; others are Niagara, Oswego, Oneida, Jefferson, Chenango, Monroe, Allegany, Greene, Rockland, Washington, Tioga, Steuben, Schuyler, Franklin, Wyoming, Essex, Chautauqua, Otsego, and Cattaraugus.

In addition to the production of sandstone in New York, a large quantity of what is commercially known as "bluestone" is quarried. Bluestone is the name given to the variety of sandstone which consists almost entirely of granules of silica cemented together by silica. The identity of this stone with sandstone is not generally recognized among the bluestone producers; in fact, many of them seem almost indignant if it is called sandstone. The bluestone industry is entirely distinct from what is herein given as the sandstone industry. Owing to the hardness and durability of bluestone, as well as the manner in which it occurs in the earth, it is well adapted to purposes of street paving, such as flagging and curbing, and most of it is devoted to these uses. A certain amount of the stone is quarried from regularly organized quarries, with a definitely invested capital and plant and good facilities for quarrying, but a large amount is produced irregularly and spasmodically by men who invest no capital and have no definite organization as producers of stone. Their operations are conducted as follows: Provided with a very simple equipment of the most ordinary quarry tools, they dislodge the stone found on land belonging to other persons and transport it to a number of shipping points, selling it there to dealers who make a business of collecting the stone in this manner and shipping it to places where it is used. The dealers pay the individuals who quarry the stone an amount which simply compensates them for their time and labor, while the owner of the property receives a certain definite percentage from the dealer for the amount of stone thus taken from his land. During the year 1889, and a number of years previous, some of the dealers at various points in New York State constituted the members of the Union Bluestone Company, with headquarters in New York City. Each member of this company was entitled to furnish a certain percentage of the total amount sold by this company in a given year. The dealers may, therefore, be regarded in a certain sense as producers. The land on which this stone is quarried is, generally speaking, of little value for anything but the bluestone containedn (sic) it. Originally the stone was quarried for flagging only, but more recently it has been applied to quite a long list of purposes, such as rubble, masonry, retaining walls, and bridge stone, curbing, gutters, hitching posts, house trimmings, such as platforms, steps, door and window sills, lintels, and caps.

The stone is known commercially by a number of names which designate approximately the region from which it is taken. Among the names in common use may be mentioned the following: Hudson River bluestone, Hudson River flagging, North River bluestone, North River flagging, Pennsylvania bluestone, Wyoming Valley bluestone, Delaware River bluestone, Delaware flags, bluestone flagging, and bluestone.

The value of the bluestone produced in New York in 1889 was $1,303,321. This product came from 142 quarries, in addition to numerous minor quarries or holes from which the product was taken by laborers, as has already been described. The productive counties are seen in the following list: Ulster, $662,324; Delaware, $150,866; Chenango, $93,100; Sullivan, $87,930; Wyoming, $50,260; Schenectady, $47,906; Orange, 33,405; Albany, $23,285, and small amounts from Otsego, Jefferson, Tompkins, Schoharie, Steuben, Seneca, Green, Chemung, Broome, Saratoga, Oneida, Rockland, Franklin, Washington, and Yates. The Union Bluestone Company, as organized in 1889, has dissolved.

No canvass of the bluestone producers has been made since 1889, when the census figures, which were collected with great care by personal visitation of all producing localities, gave the values and distribution above stated. It is safe, however, to estimate the output for 1894 at $900,000, as production has fallen off in value since 1889.

The following article, originally published in "Stone" for July, 1893, is of interest as showing the peculiarities of bluestone quarrying:

The quarrying of bluestone probably requires as much skill, if not more, than any other kind of stone, a fact often overlooked, and a potent factor in the success or failure of a quarryman. It seems to be the general impression among a great many users, and perhaps a few of the producers, of this most useful and durable stone that a man need only find a deposit of salable quality of bluestone, with no more than the usual proportion of top to bed, and with the usual shipping facilities, and success is assured, but for any one who has been closely connected with this especially interesting business it is easy to find the reason why a quarry has not paid. The causes are usually radical, and one of the first flaws, after ascertaining that the quarry contains stone in fair quantity, will be found by looking into the system of quarrying, wherein usually inheres the drawback to the prosperity of the quarry.

The peculiar formation of bluestone, and the fact that it is found in comparatively small deposits, make the use of machinery impracticable, a quarry in Chenango County, N. Y., probably being the only one which uses any of the modern machinery or blasting devices in quarrying, such as the Knox system, in use at this place. Some few of the other large quarries, perhaps, are using the Knox system in blasting their top rock, and quite a number are equipped with steam drills, but it is safe to say that 90 per cent of all the bluestone is quarried by hand wedges and sledges. Flagging is a large percentage of the kind produced, and runs from one-fourth inch thick up. The beds usually produce the thinner stone on top, running heavier as the bed is worked down. Nearly every quarry has its own peculiar formation. Quarries within 400 or 500 yards of each other frequently differ greatly as to quality and formation. As a role the best quarrymen have worked in the quarries from the time they have been able to do anything, and as that is usually pretty early in life, many of them have gained such knowledge of the work that they know to a certainty how the stone will work as soon as they see the bed, without raising a lift. It is only after long work at quarrying that a man becomes expert. In raising the flat it is very necessary that they come up in as large pieces as possible, that the cutters may get the larger-sized stone most in demand and for which the best prices are obtained. A good quarryman will handle a lift with utmost skill, driving the wedges just enough to give it the proper strain to fee itself from the bed of stone, and yet not so to strain it that it will break under the stonecutter's tool, or perhaps before it is raised. There are no general rules or directions to follow; only knowledge and skill obtained by long and close attention to the work are of any service.

Ohio. -This State stands in first place among all the States of the Union for its output of sandstone. The value of the product in 1894 is $1,777,034. The financial depression during the past two years has been severely felt by the sandstone producers of the State. In 1890 the total value amounted to $3,046,656. The productive counties in order of importance, are as follows: Cuyahoga, Loraine, Stark, Scioto, Muskingum; the smaller amounts from Crawford, Richland, Holmes, Franklin, Lucas, Meigs, Montgomery, Ross, Licking, Guernsey, Columbiana, Perry, Portage, Wood, Ashland, Pike, and Lawrence. By far the most of the stone comes from Cuyahoga and Lorain counties, in the northern part of the State.

Some of the sandstone quarries of Cuyahoga and Lorain counties are operated in a most thorough, complete, and economical manner; the latest appliances are in use, and for smoothness of working very few quarries in the country can compare with them. The use of the Knox system of blasting in the quarries of this State is attended with great success. The stone is of such a thoroughly homogeneous character that the result of a blast by the Knox system is simply to move, slightly, large masses of stone without spalling or weakening them in any manner. One could almost stand upon the mass of rock while being blasted out without danger of personal injury.

The uses to which Ohio sandstone is put are as follows: About one-sixth is consumed for abrasive purposes, for which the stone has a very high reputation. It supplies most of the demand in the United States for grindstones, etc. Somewhat more than one-half is used for building. About one-seventh is devoted to street work; while the remainder is consumed in bridge, dam and railroad construction.

Pennsylvania. -The value of the product in 1894 was $349,787. A great many quarries ceased operations entirely during the past year, demand being very light and prices lower than heretofore. The following are the productive counties, in order of importance: Beaver, Dauphin, Lawrence, Allegheny, Westermoreland, Montgomery, Lackawanna, Fayette, Luzerne, and Somerset; and small amounts from Huntingdon, Bucks, Chester, Tioga, Philadelphia, Lancaster, Indiana, Berks, Blair, Lehigh, Erie, Lebanon, Clearfield, Lycoming, Venango, Jefferson, Cambria, Warren, Elk, Crawford, Armstrong, clarion, McKean, Delaware, Greene, and Susquehanna.

South Dakota. -The total output reached a valuation of $9,000. The industry is a new one in this State, but there is reason to believe that it will develop considerably in the course of the next decade.

Texas. -The value of the output was $62,350, which is quite an increase over the product of a few years ago. The output comes from quarries in Washington, Parker, Grimes, Llano, Brown, Collin, and Wise counties.

Utah. -The value of the output of 1894 was $15,428. The productive counties are Utah, Summit, Emery, Boxelder.

Virginia. -The production of sandstone in Virginia has thus far been very limited. Campbell and Prince William counties have yielded most of the product.

Washington. -Although very fine sandstone is known to occur on the shores of Lake Whatcom, but very little has yet been done in the way of development. The product of 1894 is valued at $6,611.

West Virginia. -In this State there are large quantities of sandstone admirably adapted for use in heavy foundation work, and particularly bridge work. Productive counties are Kanawha, Wood, Summers, Ohio, Marion, Lewis, Preston, Ritchie, Harrison, McDowell, and Taylor. The value of the output in 1894 was $63,865.

Wisconsin. -This State produced $94,888 worth of sandstone in 1894. This amount differs but little from that of 1893. Productive counties are Bayfield, Pierce, Douglas, Ashland, Dunn; small amounts have been taken from the following: Sauk, Lafayette, Monroe, Portage, Jackson, La Crosse, Trempealeau, Dane, and Grant.

Wyoming. -Quarrying in this State is in its infancy, although there appear to be many possibilities well worth investigation when the demand for sandstone is such as to justify it. Stone has been produced in Laramie, Albany, Converse, Carbon, and Sweetwater counties.

Commercial use of material within this site is strictly prohibited. It is not to be captured, reworked, and placed inside another web site ©. All rights reserved. Peggy B. and George (Pat) Perazzo.