Quarries in Missouri & Quarry Links, Photographs, and

Articles

Granite / Graniteville

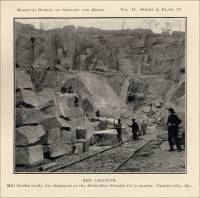

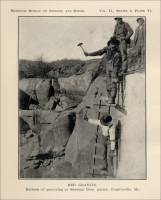

- Graniteville, Missouri - Photographs of the Graniteville Area (The following information is from The Quarrying Industry of Missouri, by E. R. Buckley, Director and State Geologist, and H. A. Buehler, Missouri Bureau of Geology and Mines Vol. II, 2nd Series, 1904.)

- Graniteville, Missouri - the Graniteville Granite Quarries (The following information is from The Quarrying Industry of Missouri, by E. R. Buckley, Director and State Geologist, and H. A. Buehler, Missouri Bureau of Geology and Mines Vol. II, 2nd Series, 1904.)

“The largest and most important granite quarries in the State are located at Graniteville five miles northwest of Ironton, the county seat of Iron County. As may be seen by consulting the map of the district, the granite areas in this vicinity are comparatively small, consisting of two outcrops, a half a mile apart. The color, texture and composition of the stone at the two places indicate that they belong to the same granitic mass.

“The north outcrop consists of an elongated hill or ridge one and three-fourths miles long and one-fourth to three-eights of a mile wide. This granite is flanked on all sides, except the northeast, with limestone of Cambrian age. On the northeast side it grades into porphyry. The hill rises rather gradually from 100 to 130 feet above the surrounding country. The quarries on this hill produce the greater part of the monumental and dimensional granite quarried in the State.

“The south outcrop is locally known as the ‘wild cat.’ It is about a half a mile long by a fourth of a mile broad. The granite is very similar to that at Graniteville. A quarry was opened on this hill several years ago, but very little stone has been taken out.

“The granite of this locality has a very uniform texture and color. The essential constituents are orthoclase, quartz and biotite. The individuals of feldspar and quartz are intricately interlocked and seldom have crystal faces. The grains are of medium size. Occasional larg (sic) feldspar crystals, sometimes two inches long, occur imbedded in the granitic ground-mass, giving the granite a porphyritic texture. Occasionally, the feldspar, quartz and biotite individuals are seggregated (sic), separately, in large masses, rendering the stone unfit for structural work. The color of the granite, which is a deep red, is quite uniform throughout the different quarries. It is due to the pink feldspar and red iron oxide constituents. Most of the quartz is translucent. The biotite and hornblende have very little effect upon the color of the stone.

“The preponderance of the two relatively hard minerals, feldspar and quartz, render the granite susceptible to a very high polish.

“Probably one of the most striking illustrations of the way in which granite weathers occurs at Graniteville, where huge residual boulders are scattered over the surface. Just west of Graniteville these are especially picturesque and instructive, and on account of their peculiar shape are known as the ‘elephant rocks.’ (See Frontispiece.) These enormous boulders, which are from ten to twenty-five feet in diameter, have a roughly spherical or oval shape, due to weathering along the edges and corners of the blocks produced by the jointing planes. At this place the boulders occur in quite well defined rows, conforming very nearly in direction to the major system of joints. The feldspar decompose more readily than the quartz, leaving the grains of the latter protruding at the surface. The granite is frequently covered to a depth of from one to three feet with quartz grains which were loosened when the feldspar was decomposed. Upon the weathered surface and along joints and beds, kaolin, formed by the decomposition of the feldspar, frequently occurs, partially filling the space originally occupied by the feldspar.

“Examples of all stages of weathering, from that in which the surface joints are just being opened through decomposition, to that in which the blocks between the joints are entirely rounded, may be seen in this area. The sap rarely extends beyond a few inches into the stone.

“The quarries are being operated at this place by the Schneider Granite Company, the Syenite Granite Company and Sheahan Bros.”

“Résumé.

“The granite in this area has the deepest red color of any in the State. Both in texture and color, it is very uniform in all the quarries and throughout the area. Granite blocks for any purpose and of any desired dimensions can be obtained. The size of the blocks is limited only by the carrying capacity of the derricks. For monuments this granite is very popular and is shipped to practically every State in the Union, including those in New England where an abundance of excellent granite is quarried. Monuments, in which the die is Missouri red granite, and the cap and base a light gray eastern granite, are frequently constructed. This makes a very attractive combination.

“The granite takes an excellent rock faced finish and when alternated with polished courses in the walls of buildings it has a striking appearance. It takes an excellent and lasting polish.

“Up to 1889, these quarries did a very large business in cut stone work, but in that year the employees went out on a strike, since which time a comparatively small amount of the stone has been cut or polished.

“The first granite paving blocks used in St. Louis were furnised (sic) by Phillip Schneider, about 1877, and were laid at the end of the Third street bridge. Since that time, these quarries have produced millions of paving blocks, which have been used chiefly in St. Louis. The partially decomposed boulders, lying upon the surface, were the first to be used. These were comparatively soft and proved very unsatisfactory. At present (circa 1904), none but the fresh, unaltered granite is used. Comparatively few blocks are now being made. Flagging and curbing have been produced to a considerable extent and used in St. Louis. For these purposes it is very durable, being practically indestructible.

“Although only three quarries are operated in this area, there are, in the immediate vicinity of Graniteville, excellent locations for new quarries. Just south of the Schneider quarry, there is a large outcrop of excellent granite, in which the stone apparently occurs in large rectangular blocks. At the so-called ‘Buzzard’s roost,’ between the Syenite and Schneider quarries (See Plate VIII.), there is a knob containing an almost unlimited quantity of excellent granite. West of Graniteville, in the vicinity of ‘Elephant Rock,’ there are excellent opportunities for quarrying.

“The area covered by the large surface boulders has been wisely protected from the quarrymen, and these most excellent illustrations of the sub-aereal decomposition of granite have not been molested.”

(Please Note: The section that lists the names and locations of important buildings constructed wholly or in part of granite from the Graniteville area is not included in this section. You can read the list in the Missouri stone industry section. Also, the structures are individually listed in the Structures section according to the location of the structure.)

- Graniteville, Missouri - the Schreen Bros. Quarry (listed in The Mine, Quarry and Metallurgical Record of the United States, Canada, and Mexico, The Mine and Quarry News Bureau, Chicago, Ill., 1897)

- Graniteville, Missouri - a Graniteville Quarry Blast (from Stone: An Illustrated Magazine, March 1893, Vol. VI., No. IV, pp. 370)

Notes From the Quarry: “A blast in a quarry at Graniteville, Mo., recently dislodged 160,000 cubic feet of stone, all in one mass.”

- Graniteville, Iron County, Missouri - A. J. Sheahan’s Granite Quarry (from“Notes on The Building Stones, Clays and Sands of Iron, St. Francois and Madison Counties,” by G. E. Ladd, Assistant Geologist, in Bulletin 1, Geological Survey of Missouri, Jefferson City, April 1890.)

“H. A. Sheahan. In township 34 north, range 3 east, a little south of the ‘Syenite Granite’ company’s quarry, Mr. Sheahan opened a small quarry, in August, 1889. The manner of occurrence of the rock with reference to quarrying, and the character of the stone is similar to that of the Graniteville quarries. Little work has been done here. No dimension stone has as yet been quarried, and only a few thousand paving blocks have been produced, which were hauled in wagons to Middlebrook for shipment.”

- Graniteville, Missouri - A. J. Sheahan Quarry Blast (from Stone: An Illustrated Magazine, September 1892, Vol. V., No. IV)

“A. J. Shehan, the granite quarryman, put off in his quarry at Graniteville, Mo., the largest blast ever made west of the Mississippi river. The holes were put in 40 feet high, and were scattered along in a line of 100 feet. The result was that 160,000 cubic feet of granite were cut off the ledge, and all in one solid piece, without a seam or crack.”

- Graniteville, Missouri - A. J. Sheahan Quarry Blast (from Stone: An Illustrated Magazine, September 1892, Vol. V., No. IV)

- Graniteville, Missouri - A. J. Sheahan Granite Company

(Advertisement) (from American Stone Trade Magazine,

Vol. XXVIII, No. 3, October 1927, Chicago, Illinois, pp. 49)

Red Missouri Granite - Unequalled for memorial Purposes

As an All-polished Spire of Sheahan’s Missouri Red Syenite Granite at Vicksburg, Miss.

Known to the trade as Sheahan’s Missouri Red, it is the best choice for memorials of all kinds and shapes - Vaults and Public Monuments as well as family memorials.

A. J. Sheahan Granite Company, Quarriers, Graniteville, Mo.

- Graniteville, Missouri - the A. J. Sheahan Granite

Company, Quarriers (Advertisement) (from American

Stone Trade, June, 1929, pp. 19.)

Missouri Red Granite - Unequaled for Memorials

The most resplendent red when polished, and when fine axed it is the warm pink most desired for art expressions. Known to the trade as Sheahan’s Missouri Red, it is always the best choice for Vaults and Public Monuments, as well as Family Memorials.

We supply rough stock only - Any size - any quantity.

A. J. Sheahan Granite Co., Quarriers, Graniteville, Mo.

- Graniteville, Missouri - the A. J. Sheahan Granite

Co., Quarriers (Advertisement) (from American

Stone Trade, July, 1931, Vol. XXXI, No. 12, pp. 16.)

(This same advertisement also ran in the following issues

of American Stone Trade: November, 1931, Vol. XXXII,

No. 4, pp. 9; December, 1931, Vol. XXXII, No. 5, pp. 9; January,

1932, Vol. XXXII, No. 6, pp. 5; and February, 1932, Vol. XXXII,

No. 7, pp. 5.)

Illustration shows the Adolphus Busch Memorial, Bellefontaine Cemetery, St. Louis, Mo. Executed and erected by the Pickel Stone Co., Out of Sheahan’s Dark Syenite.

Missouri Red Granite - Unequaled for Memorials

The most resplendent red when polished, and when fine axed it is the warm pink most desired for art expressions. Known to the trade as Sheahan’s Missouri Red, it is always the best choice for Vaults and Public Monuments, as well as Family Memorials.

We supply rough stock only. any size - any quantity.

A. J. Sheahan Granite Co., Quarriers, Graniteville, Mo.

- Graniteville, Missouri - the A. J. Sheahan Granite

Co., Quarriers (Advertisement) (from American

Stone Trade, April, 1932, Vol. XXXII, No. 9, pp. 4.)

The Famous Buckingham Memorial Fountain in Grant Park, Chicago (Illinois). The polished columns of the Buckingham Fountain were cut in our granite.

Missouri Red Granite - Unequaled for Memorials

The most resplendent red when polished, and when fine axed it is the warm pink most desired for art expressions.

Known to the trade as Sheahan’s Missouri Red, it is always the best choice for Vaults and Public Monuments, as well as Family Memorials. Quarry facilities for prompt shipment were never better than at the present time.

We supply rough stock only. Any size - any quantity.

A. J. Sheahan Granite Co.

Quarriers, Graniteville, Missouri

- Graniteville, Missouri - A. J. Sheahan Granite Co.,

Quarriers (Advertisement) (from American Stone

Trade, August, 1932, Vol. XXXIII, No. 1, pp. 29.)

Sheahan’s (Dark Syenite)

Unequaled for Dignified Memorials - The First Choice Brick Building Trim

True Fresh Color For Statues - Keeps Its Polish For the Ages.

We Supply Rough Blocks Only

A.J. Shehan Granite Co., Quarriers, Graniteville, MO.

- Graniteville, Missouri - A. J. Sheahan Granite Co.,

Quarriers (Advertisement) (from American Stone

Trade, October, 1932, Vol. XXXIII, No. 3, pp. 14.) (The

same advertisement also appeared in the following editions

of American Stone Trade magazine: February, 1933,

Vol. XXXIII, No. 7, pp. 12; April, 1933, XXXIII, No. 9, pp.

10; June, 1933, XXXIII, No. 11, pp. 9; November, 1933, XXXIV,

No. 4, pp. 4; December, 1933, XXXIV, No. 5, pp. 4; January,

1934, XXXIV, No. 6, pp. 4; March, 1934, XXXIV, No. 8, pp.

3; and July, 1934, XXXIV, No. 12, pp. 9.)

(To see the photograph used in this advertisement, see the

A. J. Sheahan Granite Co. April 1932 advertisement above.)

Missouri Red Granite - Unequaled for Memorials

The most resplendent red when polished, and when fine axed it is the warm pink most desired for art expressions.

Known to the trade as Sheahan’s Missouri Red, it is always the best choice for Vaults and Public Monuments, as well as Family Memorials. Quarry facilities for prompt shipment were never better than at the present.

We supply rough stock only. Any size - any quantity.

A. J. Sheahan Granite Co. Quarriers - Graniteville, Missouri

(Photo caption: The Famous Buckingham Memorial Fountain in Grant Park, Chicago. The polished columns of the Buckingham Fountain were cut in our granite by J.P. Bourgoin & co., Elmwood, Illinois.)

- Graniteville, Missouri

- A. J. Sheahan Granite Co., Quarriers (Advertisement)(from American

Stone Trade, August, 1933, XXXIV, No. 1, pp. 19. The

same advertisement ran in the following issues of American

Stone Trade: September, 1933, XXXIV, No. 2, September,

1933.)

The Champ Clark Monument with Polished Pedestal.

The Beacham Memorial Polished and Carved.

The Adler All Axed Spire.

Missouri Red Granite - A True Syenite

The Most Resplendent Red for Polishing - When Fine Axes it is About Perfect Flesh Color

Sold in Stock Patterns of all Sizes and All Quantities. Send orders in any quantities to

A. J. Sheahan Granite Company, Quarriers, Graniteville, MO

- Graniteville, Missouri - A. J. Sheahan Granite Co.,

Quarriers (Advertisement) (from American Stone Trade,

August, 1934, XXXV, No. 1, inside back cover)

The Champ Clark Monument with Polished Pedestal.

The Famous Buckingham Memorial Fountain in Grant Park, Chicago.

Examples of Memorials of the popular type executed in Sheahan’s Missouri Red Granite.

Missouri Red Granite, A True Syenite

The Most Resplendent Red For Polishing - When Fine Axed It is About Perfect Flesh Color

Sheahan’s Red Missouri Granite is a bright deep red when polished and has a live warm tone when fine axed. It has proved its enduring qualities in an endless number of examples, and it has a remarkable contrast for the contrasts wanted in finishing the finest work. You will find this granite to be your best choice for Vaults and Public Monuments as well as Family Memorials.

We Supply Rough St ock Only - Any Sizes - Any Quantities.

A. J. Sheahan Granite Co., Quarriers, Graniteville, Missouri

- Graniteville, Missouri - A. J. Sheahan Granite Co.,

Quarriers (Advertisement) (from American Stone

Trade, December, 1934, XXXV, No. 5, pp. 22.)

Missouri Red Granite

Your Orders for Rough Stock Patters in sizes and quantities to meet your needs will be supplied promptly in the purest red granite known to the trade -- When polished it is like the ruby jewels when fine axed it has the lifelike pink color both these color values are permanent. Monuments in Missouri Red Granite are as good as new after 50 years. You can build up your business by using this stock.. We supply rough stock only. Any size - any quantity.

A. J. Sheahan Granite Co., Quarriers, Graniteville, Missouri

- Graniteville, Iron County, Missouri - Andrew Jackson Sheahan (Obituary) of the A. J. Sheahan Granite Co. (from American Stone Trade, May, 1936, Vol. XXXVI, No. 9, pp. 13.

“Andrew Jackson Sheahan, 77, of Graniteville, Mo., passed away at his home in Graniteville, on February 20, 1936. He was the president of the A. J. Sheahan Granite Co., of that city who have quarried Missouri red granite for the trade for many years.

“Mr. Sheahan was born in Rockport, Mass., on January 1, 1859, and came west to Missouri with his twin brother, when only nineteen years old. He found employment in Piedmont, St. Louis and Graniteville and eventually took over the further development of a valuable granite deposit and formed the company which bears his name. His wife, Emma Murphy, whom he married in 1882, died nearly twenty-seven years ago. They had four children, Andrew Timothy Sheahan, who died two years ago, Edward C. Sheahan, of Graniteville, Mrs. Ella Collins, of Arcadia and Mae Sheahan, of Graniteville. A man of deep faith and sterling worth, the business dealings of Mr. Sheahan were characterized by honesty, fair play and cooperation to all. The example of his fine character is a great heritage he has left to his children.”

- Graniteville, Missouri - the A. J. Sheahan Granite

Company, Quarriers (Advertisement) (from American

Stone Trade, June, 1929, pp. 19.)

- Graniteville, Iron County, Missouri - A. J. Sheahan

Also see: “Graniteville (west of), Missouri - the Sheahan Bros. Granite Quarry” below.

- Graniteville, Missouri - Granite Quarry (circa 1967) (From Mining and Mineral Operations in the United States: A Visitor’s Guide, by Staff, Bureau of Mines, Area Mineral Resource Offices, U. S. Department of the Interior, Bureau of Mines, 1967, pp. 37.)

“Mo. 21. - Granite for building and monumental stone is quarried and prepared at Graniteville, a few miles northwest of Ironton. The operation may be observed from a public road, or tourists may obtain permission to tour the plant by contacting the plant manager.”

- Graniteville Area, Iron County, Missouri - J. S. Benson

Porphyry Quarry (Porphyry) (from “Notes

on The Building Stones, Clays and Sands of Iron, St. Francois

and Madison Counties,” by G. E. Ladd, Assistant Geologist,

in Bulletin 1, Geological Survey of Missouri, Jefferson

City, April 1890.)

“J. S. Benson. In township 31 north, range 4 east, section 14 east half, about three miles from the railroad, is a small quarry in porphyry, opened in the spring of 1888. About 700,000 paving blocks have been produced to date here, which were shipped to St. Louis and Memphis. The rock is too full of joint planes to permit of its being quarried for dimension stone; but it splits well and is easily made into paving blocks. Its color varies from dark blue to pink.”

- Graniteville Area, Iron County, Missouri - the J. S. Benson Porphyry Quarry (Porphyry), (location & map) (from Brainy Geography)

- Graniteville, Missouri - Missouri Red Granite Co. (Advertisement) (from American Stone Trade Magazine, Vol. XXVIII, No. 3, October 1927, Chicago, Illinois, pp. 25)

Wholesale Manufacturer Finished Monuments and Building Work In Missouri Red Granite

We operate our own quarries at Graniteville, Mo., and are prepared to furnish any stock for monumental and building work, also paving blocks. Send us your inquiries for estimate.

Missouri Red Granite Co., Incorporated, Arlington Ave. and Terminal Railroad, St. Louis, Mo.

- Graniteville (south of), Iron County, Missouri - the Ozark Mountain Granite Quarry (Granite) (from“Notes on The Building Stones, Clays and Sands of Iron, St. Francois and Madison Counties,” by G. E. Ladd, Assistant Geologist, in Bulletin 1, Geological Survey of Missouri, Jefferson City, April 1890.)

“Ozark Mountain. About a quarter of a mile south of Graniteville is a quarry which was opened in 1869, and which is the oldest granite quarry in Missouri. It is in the same outcrop as the Graniteville quarry and the stone answers to the same description. The quarry is not now worked, but, when in operation, from five to six hundred men have been employed here at one time. Stone from this quarry was used in the construction of the famous Eads bridge across the Mississippi, of the Illinois and Iowa State houses, of the St. Louis and Cincinnati custom houses, and of the Memphis and Little Rock post-offices. The stone taken out was, however, inferior to what can be obtained, as it was mostly surface rock.”

- Graniteville (south of), Iron County, Missouri - the Ozark Mountain Granite Quarry (Granite), (location) (from Brainy Geography)

- Graniteville Area, Iron County, Missouri - the Pilot Knob Company Granite Quarry (Granite) (from“Notes on The Building Stones, Clays and Sands of Iron, St. Francois and Madison Counties,” by G. E. Ladd, Assistant Geologist, in Bulletin 1, Geological Survey of Missouri, Jefferson City, April 1890.)

“Pilot Knob Company. In township 34 north, range 3 east, section 22, center of southern half, there is a very small quarry belonging to the Pilot Knob company, from which a few paving blocks have been quarried. The outcrop of granite is very large here, and can probably be quarried advantageously for dimension stone, as the joint planes seem to be so situated as to facilitate quarrying, and yet not to interfere with the production of large blocks. The stone is composed of grains of clear transparent quartz and of crystals of dark pink feldspar, which latter give it a reddish color. It takes an excellent polish.”

- Graniteville, Iron County, Missouri - the Pilot Knob Granite Quarry (Granite) (location & location) (from Brainy Geography)

- Graniteville, Iron Mountain (4 miles west of), Iron County, Missouri - the Philip Schneider & Co. Quarry (Granite) (from Report on The Building Stones of The United States, and Statistics of the Quarry Industry for 1880, by George W. Hawes, Curator of the Department of Mineralogy and Lithology at the National Museum, and by F. W. Sperr and Thomas C. Kelly, Joint production of the Census Office and the National Museum, 1883)

The following information was taken from the table entitled, “Table IV. Tables indicating the Amount and Kinds of Rock in the Different States”: The Philip Schneider & Co. Quarry, 4 miles west of Iron Mountain, Iron County, Granite/Granite, color: Red; quarry opened in 1873.

“Only recently (prior to 1880) has much attention been directed to the quarrying of granite. There are but two quarries worked to any extent, the stone from which is used for paving streets and for general building purposes, principally in the city of Saint Louis. The stone from a quarry 4 miles west of Iron Mountain, Iron county, has been used in a pavement on Washington avenue, Saint Louis, for about 6 years, and the pavement is still in good order. The flagging around the Southern hotel, at Saint Louis, is also of this granite; also the front of the residence of Mr. Charles G. Stiefel. The amount of granite which may be obtained in this locality is practically inexhaustible.”

- Graniteville, Iron County, Missouri - the Schneider Granite Quarries (Granite) (from“Notes on The Building Stones, Clays and Sands of Iron, St. Francois and Madison Counties,” by G. E. Ladd, Assistant Geologist, in Bulletin 1, Geological Survey of Missouri, Jefferson City, April 1890.)

“Phil. Schneider. In township 34 north, range 3 east, section 10, west half, Mr. Schneider has two granite quarries which were opened in 1885. They are situated on the west slope of a granite ridge where drainage by siphons is possible and quarrying is easily carried on. The characteristics of the outcrop and of the stone are about the same as those at Graniteville...The plant consists of two stationary engines, a steam traveller (sic), six derricks, three polishers (lathe, vertical and pendulum), a short tramway, blacksmith shop, office, boarding houses, sheds, tools, etc. A railway connection, three miles long, with the St. Louis, Iron Mountain & So. ry. is contemplated. The total output to date is about six million paving blocks, in addition to an undetermined amount of dimension stone. Among the important structures for which it has furnished granite are the Lemp building, and the Moline and Merchants bridges, all of St. Louis.”

- Graniteville (north of), Missouri - the Schneider Granite Company’s Quarry (Granite) (The following information is from The Quarrying Industry of Missouri, by E. R. Buckley, Director and State Geologist, and H. A. Buehler, Missouri Bureau of Geology and Mines Vol. II, 2nd Series, 1904.)

(Also see: Graniteville (in the vicinity of), Missouri - the Syenite Granite Company’s Quarry below.)

“This company was incorporated in 1890 for $150,000, and the present officers are P. W. Schneider, Sr., president; R. P. Schneider, vice-president, and B. Schneider, secretary. The company has offices at 330-331 Lincoln Trust building, St. Louis. They control about 40 acres of land, underlain with granite suitable for quarrying. This quarry is located about three-fourths of a mile north of Graniteville in the S. E. ¼ of N. E. ¼, Sec. 10, T. 34 N. R. 3 E. It consists of two openings. One is some distance east of the plant, on the west side of the hill, and the other is southeast of the plant. The latter is being worked more extensively. It has an irregular rectangular outline, about 200 feet east and west by 150 feet north and south. A track connects it with the plant. Just north of this opening is a rectangular sunken opening, about 100 feet square and 45 feet deep. The top of this quarry is on a level with the base of the one just south of it.

“The granite is medium to coarse grained and consists mainly of orthoclase and quartz, with occasional individuals of biotite. The texture differs very little throughout the quarry. In the lower portion of the first opening, the granite is somewhat finer grained than near the surface. The color, which is a strong red, is uniform, although it is slightly deeper in the lower portions of the quarry. In the east end of the quarry there is a slightly bluish streak a foot wide. North of where the granite is being worked in the upper opening it is not quarried on account of its color.

“The quarry was opened near the northwest corner by exploding several tons of powder in two chambers at the bottom of a shaft sunk in the granite. This opened the joints over a wide area and broke a considerable quantity of the granite into very small pieces. The granite has been worked beyond this area and now presents a solid face.

“The major joints strike N. 41-45° E. and are from four to thirty-five feet apart. These are known as the ‘rift seams’ because the stone splits most readily parallel to them. The minor joints strike N. 45-50° W. and are especially numerous in the west end of the quarry, where they are from two to four feet apart. Occasional other joints strike diagonally across these. principal bedding plane is twenty-three feet from the surface and lies approximately horizontal. Dries spoil many blocks that would otherwise be perfect. These seams are usually short and often do not appear until the block is being worked in the shed. Short, disconnected, dark streaks, parallel to the rift, occur in some parts of the quarry. These are frequently an eighth of an inch wide and contain small crystals of iron pyrite which alters to yellowish brown iron oxide when exposed to the weather. Occasional, thin dark veins occur parallel to the lift. All the seams, of whatever character, cause some waste, since the monumental and building stock should be without blemishes.

“The principal bedding plane is of great assistance in getting out the stone. Above this bed solid blocks of almost any size can be obtained. Granite has been quarried about 30 feet below this bed, but no other bedding plane has been encountered. The face of this portion of the quarry is very irregular.

“From the opening just north of this an excellent granite is obtained in large blocks which are practically free from defect. The twelve polished columns in the Flood building in San Francisco, which are sixteen feet long by two feet six inches in diameter, were quarried from the lower portion of this opening. The imperfect blocks and spalls from this quarry are crushed.

“The third opening, located east of the plant, was opened by exploding a large mine of powder near the N.W. corner. This opening has an irregular triangular shape, and a vertical face of about sixty feet. The granite is very similar to that in the west opening.

“The quarry contains numerous joints which strike in many different directions. The most prominent strike N. 70° W. (dip 30-50° S. 20° W.); N. 45°; N. 80° W.; and N. 55° E. These joints, some of which were undoubtedly caused by the explosion of the mine, break the stone into such small blocks that very little dimensional stone is obtained. This granite is being used almost exclusively for paving blocks and crushing. The outcrops to the north indicate that excellent stone will be obtained when the opening is extended in that direction. Two-inch cubes of this granite gave a crushing strength of 19,452.5 pounds per square inch.

“The quarry is connected with the St. Louis, Iron Mountain and Southern railroad, at Iron Mountain, by a spur three and seven-eighths miles in length. The company owns a locomotive, large steam derricks, two No. 4 Gates crushers, having a capacity of 200 tons per day; two 60-horse power engines, and two 75-horse power boilers which furnish the power for operating the entire plant. The cutting shed is equipped with five lathes, Jennie Lind polishers and all other machinery and tools needed for cutting granite. This company is producing building stone, monumental stock, paving blocks and three sizes of crushed granite, 3/8 inch, ¾ inch and 1 ½ inch. The last is sold F. O. B., Iron Mountain tracks, at prices ranging from $1.45 to $2.00 per ton. Very few paving blocks are made, although formerly 50,000 to 60,000 were produced per month. An average of 65 men and as high as 150 men are employed, exclusive of the paving cutters. The company has yards in St. Louis, at the junction of Spring avenue and Missouri Pacific railroad tracks.

“This quarry is equipped to produce large quantities of excellent stone. A partial list of the buildings in which this stone has been used will be found at the end of this chapter.”*

(Please note that you will find the structures included in the above-cited list in the Missouri structures section of this web site according to the location of the structure.)

- Graniteville, Iron Mountain, Missouri - the Schneider

Granite Co. (Advertisement) (from Monumental News,

Vol. XXXII, No. 1, January, 1921, Allied Arts Publishing Company,

Chicago, Illinois, pp. 51. The advertisement below was also

published in The Monumental News, Vol. 34, No. 1, January,

1922, Allied Arts Publishing Company, Chicago, Illinois, pp.

69.)

Rough Stock Buyers You Can Get All The Red Missouri

Granite patterns you need. It will be just as easy to get now as it has been hard to get for the past few years. We are equipped to produce three times the amount we did last year Get your order in early.

Schneider Granite Co., Iron Mountain, Missouri

- Graniteville, Iron County, Missouri - the Phil Schneider Granite Quarries (Granite), (location & map) (from Brainy Geography)

- Graniteville Area, Iron County, Missouri - the Schneider Company’s Quarry (location & map) (from Brainy Geography)

- Graniteville, Iron County, Missouri - Schnieder’s Granite Quarry (presented on the minedat.org web site.) “Map Reference: 37°40’6"N, 90°41’36"W”

- Graniteville (west of), Missouri - the Sheahan Bros. Granite Quarry (Granite) (The following information is from The Quarrying Industry of Missouri, by E. R. Buckley, Director and State Geologist, and H. A. Buehler, Missouri Bureau of Geology and Mines Vol. II, 2nd Series, 1904.)

“The Sheahan Bros. Quarry.

“Sheahan Bros. quarry, which is located in the N. E. ¼ of the N. E. ¼ of the S. E. ¼ of sec. 15, T. 34 N., R. 3 E., just west of Graniteville, was opened in 1889 and has been operated continuously since that time. This company owns six acres of land, all of which is underlain with valuable granite. The quarry is situated on the south side of the hill, and has been opened east and west 235 feet and north and south 65 feet, and has a maximum face of forty feet. It is being extended to the west, in which direction the granite can be worked about 1,000 feet. The texture of the granite is very similar to that at the other (Graniteville) quarries, although it varies somewhat in coarseness. Near the east end of the quarry there is an irregular area, about five feet by twelve feet, in which very large crystals of feldspar, quartz and mica have segregated. Some of the granite near the east end of the quarry has such a coarse texture that it is undesirable for constructional purposes. The stone has a warm, dark red color which is quite uniform throughout the quarry. The essential constituents are orthoclase, quartz and biotite, the two former being the more abundant. The stone takes a good polish.

“At the west end of the quarry two major joints, twenty-five feet apart, strike east and west and have a dip of 19° to the north. A number of less prominent parallel joints occur between these. Two joints, striking N. 40 ° E., occur near the west central portion of the quarry. Just east of these occurs a joint which strikes N. 75° E. and has a dip of 20° S., 19° E. The joints permit the quarrying of large dimensional blocks and monumental stone, although the inclined joints often cause waste. Short dries occur in some blocks, which otherwise would make exceptionally good monumental stock.

“The surface of the quarry is covered with decomposed granite consisting of boulders imbedded in from one to two feet of coarse quartz grains. The sap forms a thin layer, from two to eight inches in thickness, at the surface and to a shallow depth along the joints. The company is working to a disadvantage owing to the limited extent of their property to the north, on account of which the joints cannot be used to advantage. The hill rises gradually to the north making an excellent place for quarrying. The land north of the quarry is leased to the Syenite Granite company.

“This quarry is producing monumental stock, dimensional stone and paving blocks. Spalls, which are shipped to St. Louis, bring seventy-five cents per ton, delivered at the St. Louis, Iron Mountain and Southern railroad.

“The equipment consists of three steam drills, two steam hoists, a large derrick, two pumps and a 100-horse power boiler. About twenty men are employed. The entire product is hauled by wagon to the railroad, a distance of two and one-fourth miles. It is expected soon to build a spur from the railroad and to erect a crushing plant.”

- Graniteville Area Iron County, Missouri - the Sheahan Brothers Granite Quarry (Granite), (location & map) (from Brainy Geography)

- Graniteville, Iron County, Missouri - the Syenite Granite Company’s Granite Quarries (Granite) (from“Notes on The Building Stones, Clays and Sands of Iron, St. Francois and Madison Counties,” by G. E. Ladd, Assistant Geologist, in Bulletin 1, Geological Survey of Missouri, Jefferson City, April 1890.)

“Graniteville. In township 34 north, range 3 east, on the southern half of the line dividing sections 10 and 11, are two quarries which have been operated since 1882 by the ‘Syenite Granite’ company. These quarries are probably the largest in the State. They are admirably located on hill slopes, which location permits of their being drained by siphons. The rock is a red granite, exposed in extensive outcrops, generally with a thin cover, necessitating little stripping. It is very easily quarried, having a good ‘bedding’ plane, and vertical joint planes, in sufficient quantities to assist the quarryman greatly in getting out stones, and yet not so abundant as to prevent the obtaining of very large blocks. The color of this stone is red or dark pink, mottled with gray and black, the red shades being due to feldspar, the others to a more or less smoky quartz. The rock takes a high, lustrous and handsome polish; but on account of excessive hardness, it is very difficult to dress.

The plant.

“The plant consists of a switch about three miles long, which connects the quarries with the Iron Mountain & Southern railway, a locomotive and two stationary engines, two steam travelers, a vertical and a lathe polisher, several derricks, steam drills, an office, a store, extensive sheds, work shops, etc.

The product.

“The product since 1882 is about 250,000 cubic feet of dimension stone, about 5,000,000 paving blocks, and a large amount of ‘rip-rap,’ which has been used for ballast by the Iron Mountain Southern railway, and also extensively in the manufacture of granitoid pavement and sidewalk flags.

Structures containing this granite.

“Among the important structures for which these quarries have supplied stone are the following:

Fagin building, St. Louis, Mo.

Odd Fellows hall, St. Louis, Mo.

Mercantile Library, St. Louis, Mo.

Roe building, St. Louis, Mo.

Singer building, St. Louis, Mo.

Commercial building, St. Louis, Mo.

Ligget & Meyer bldg., St. Louis, Mo.

Rosenheim building, St. Louis, Mo.

Meyer Bros. building, St. Louis, Mo.

Drummond tobacco factory, St. Louis, Mo.

Merchants bridge, St. Louis, Mo.

St. Louis stand pipe tower, St. Louis, Mo.

Boatmen’s Bank bldg., St. Louis, Mo.

Rookery building, Chicago, Ill.

Marshall Field bldg., Chicago, Ill.

Studebaker building, Chicago, Ill.

Savory hotel, Dubuque, Iowa.

Rialto building, Chicago, Ill.

Northwestern Guarantee Loan Co. bldg., Minneapolis, Minn.

Society for Savings building, Cleveland, Ohio.

Central Sav. Bk., Baltimore, Md.

Union Depot building, Indianapolis, Ind.

City Hall bldg., Cincinnati, O.

Cincinnati art museum, Cincinnati, O.

Ǽtna Bank bldg., Cincinnati, O.

German Savings Bank, Cincinnati, O.

Whitney National Bank, New Orleans, La.

Morris bldg., New Orleans, La.

Oriental hotel (now in construction - circa 1890)

Paxton building, Omaha, Neb.

Heest bldg., Kansas City, Mo.

Corrigan building, Kansas City, Mo.

Sizes of blocks produced.

“Among the largest pieces of dimension stone which have been quarried here are: The Allen monument in Pittsfield, Mass., which is 42 feet high and 4 ½ feet square at the base, and weighs about 45 tons; the columns in the front of the Studebaker building, in Chicago, which are ten in number and are each 18 feet high and 4 ½ feet in diameter, and weigh about 18 tons; and the window sills in a Chicago building, on Adams street, between Fifth avenue and Franklin, which are each 3 feet square by 17 feet 4 inches long.”

- Graniteville (in the vicinity of), Missouri - the Syenite Granite Company’s Quarry (The following information is from The Quarrying Industry of Missouri, by E. R. Buckley, Director and State Geologist, and H. A. Buehler, Missouri Bureau of Geology and Mines Vol. II, 2nd Series, 1904.)

“The Syenite Granite Company’s Quarry.

“The first quarry operated by this company at Syenite was opened in August, 1880, and abandoned about 1890. March, 1882, the company leased all the granite land, in the vicinity of Graniteville, owned by the Iron Mountain Ore Company. The first quarrying by this company at Graniteville was in the opening formerly worked by Mr. Schneider just west of the company’s store. Two years later an opening, which is still operated, was made north of Graniteville, in the S.W. ¼ of the S. W. ¼, sec. 11, T. 34, R. 3 E. The officers of the company are R. W. Allen, president, T. F. Wash, vice-president, and H. W. Allen, secretary. The company has offices at Graniteville and at 125 S. 4 th street, St. Louis, Missouri.

“The opening which is being worked extends into the hill about 340 feet and has a south face 500 feet long. The face is ten feet in height near the west end and gradually increases to approximately sixty feet near the east end.

“This quarry was opened by exploding twenty thousand pounds of powder in each of two chambers eighty feet apart and eighty feet below the surface. Before exploding the powder, the shaft and drifts connecting the chambers were filled with spalls. The discharge of these mines opened the joints over a considerable area, and in close proximity to the chambers the stone has broken into very small pieces.

“The essential constituents of the granite are orthoclase and quartz. The grains are of medium size, although there is an occasional feldspar crystal two inches in length. Biotite is a minor constituent which is occasionally segregated in masses of variable size. The color which is a warm, dark red, similar in most respects to the granite at the other (Graniteville) quarries, is very uniform throughout the quarry.

“The major joints strike N. 60° E., dip about 10° and are from two to twenty-five feet apart. minor set which is poorly developed in this quarry strikes at right angles to the first set. Near the middle of the quarry face, when inspected, there were two inclined joints about five feet apart, dipping E. 12° 20° from the horizontal. Occasional dark seams, as in the Schneider quarry, occur parallel to the major joints. They often contain small crystals of pyrite.

“The principal bedding plane, near the east end, is forty-two feet from the surface. This is of great service in quarrying the stone in the upper part of the quarry. At this same place, a minor bedding plane occurs about thirteen feet from the surface. Short dries occur in some of the blocks, although a large proportion of the stone is free from these seams. The joints are so situated with respect to one another as to permit the quarrying of blocks of any desired size. The dimensions are limited only by transportation facilities.

“Most of the granite is being obtained from the east end where the face is exceptionally good, especially in the upper bed. Near the middle of the quarry, the joints are more numerous and the granite is not as good. At this place, about six feet from the top of the upper bed, there are a number of segregations of mica, the two larger of which are twelve inches in length by two inches in thickness. These are not common in this quarry, the above being the only ones observed.

“At the east end the quarry has been worked about twenty-five feet below the upper bed, giving a maximum face of 65 feet. The lower part contains excellent large blocks of number one granite. The upper six or eight feet is partially decomposed and, as a rule, is used only for crushing. The amount of excellent stone that can be quarried from this opening is practically inexhaustible.

“The so-called ‘West’ quarry is located just west of the office. This opening has an east and west face f about 125 feet and a north and south face of 80 feet. It was worked about two years before the other quarry was opened, but has not been operated since that time. It produced some excellent granite, including the Allen monument, erected at Pittsfield, Massachusetts, which is a polished column forty-two feet in length and having a base four feet two inches square. (See Plate IX.) However, the granite is not very accessible and for this reason it will probably not be worked again by this company.

“The quarry is connected by a spur with the St. Louis, Iron Mountain and Southern railroad, at Middlebrook, three miles distant. The company owns a locomotive and the quarry is equipped with two large derricks, two steam hoists, three Ingersoll-Sergeant steam drills and all necessary hand tools. The cutting sheds contain two lathes, four vertical polishing machines and necessary accessories. Both finished and rough monumental and building stock, and paving blocks are produced. The major part of the output is rough stock for monuments and buildings. Since 1889, owing to labor difficulties, very little attention has been given to finished work.

“A partial list of the buildings and monuments in which this stone has been used will be found at the close of this chapter.”*

(Please note that you will find the structures included in the above-cited list in the Missouri structures section of this web site according to the location of the structure.)

Commercial use of material within this site is strictly prohibited. It is not to be captured, reworked, and placed inside another web site ©. All rights reserved. Peggy B. and George (Pat) Perazzo.