List of Quarries

in Vermont & Quarry

Links, Photographs and Articles

- Rutland, Vermont (Also see the: West Rutland, Vermont, section.)

- Rutland, Vermont - Marble Valley

- Rutland, Vermont - Marble Valley, Rutland, Vermont

- Rutland, Vermont - Marble Quarry Near Rutland, Vermont

- Rutland, Vermont - Showing Channeling Machine at work in Marble Quarry

- Rutland, Vermont - Traveling Crane, Center Rutland, Vermont

- Rutland County, Vermont - Rutland County Marble, with

a History of the Marble Industry of Vermont up through 1872.

The following paper is an excerpt from the First Annual Report of the Vermont State Board of Agriculture, Manufactures and Mining, for The Year 1872, by Peter Collier, Secretary of the Board Montpelier, J. & J. M., Poland’s Steam Printing Establishment, 1872, “Rutland County Marble, with a History of the Marble Industry of Vermont, and a Statement of Comparative Value,” An address delivered before the State Board of Agriculture, &C., at Burlington, Jan. 24, 1872, By J. E. Manley, Esq., of West Rutland. (pp. 656-666).

“In the creative wisdom of God, displayed alike in the creation of earth and man, we are to suppose that the earth from the first had been preparing for the service of man. For him the ‘darkness’ and ‘waste’ which had rested upon the earth through periods of rest and activity, had been restored to order and beauty, forming part of a system of means, pointing to the success and prosperity of man, the subordinate end. From time to time organic fires had crystallized the granite and piled it into lofty table lands, and the never wearied waters had washed it down to extensive plains of vegetable soil. The earth, vibrating with electrical shocks, has become veined with metallic ores. In the ages of comparative quiet through which the earth passed, long accumulating vegetation of preceding periods was for man transmuted into stores of fuel. The ferruginous deposits of primeval waters were becoming iron, and for man successive races of destroyed animals were changed to useful limestone; the interior of the earth becoming a storehouse, containing everything for the service of man, so that when the time should come for him to open and gaze upon her treasure, ‘the blessings of the deep which lieth under,’ he might gratefully recognize the benevolent foresight and wisdom of Him who had placed them there.

“Perhaps this wisdom is not more displayed in any of the deposits than is manifest in the deposit of limestone, usually termed marble, embracing a system not manifest in anything else which God has made. The deposits of marble in Rutland county and in the State present a different appearance and texture in almost every opening not upon the same strata. The quarries at West Rutland, the most celebrated in the United States, are mostly upon the same deposit - dip to the east at the surface at an angle of about 45 deg.; although in some of the openings the strata is more erect, and in others less than 45 deg. There are openings of recent date upon the west of those most celebrated; and the longest worked, and located at the base of the West Mountain, dip also to the east at an angle varying from 38 to 45 degrees. These openings, one of which dates back as one of the first in Rutland county, are not as compact, and are upon the same strata more changeable in texture and color, than the older worked and more extensive quarries of which I shall directly speak. One of these at the base of the West Mountain contains serpentine and verd-antique marble, the texture of which is very uneven, and when exposed to the sun and rain becomes more brittle and hard (sic) than any other marble known to the trade. The composition of verd-antique marble not being the same as other marbles accounts, perhaps, for the unusual condition from exposure. This marble is not now quarried, and I have been thus particular in its description, as there is no other marble quarried in Rutland county resembling it except the brocatelle, known to the trade as ‘brocadilla.’ The deposit known as the quarry of the Green Mountain Marble Company is developed about 50 feet in width, and consists of eleven layers, varying from 2 ½ to 5 feet I width. The No. 1 and average marble in this quarry composes about one half of the opening, and has proved to be very desirable marble, and sound at a depth of 25 feet from the surface. The marble upon the surface of this quarry was simply decomposed limestone, and all the layer was very soft when the quarry was first opened, - illustrating a principle that to be sure of a sound quarry, soft and decomposed marble is generally found upon the surface, and also where the marble is fine and hard upon the surface, usually great depths are attained before sound marble is reached.

“These recently opened, as above stated, embrace a large proportion of the white marble, and some of the layers are very fine, and much sought by dealers for carving purposes. The older and more extensively worked and most valuable quarries embrace a width of 110 feet, consisting of 24 layers of marble at present quarried, sawed and placed upon the market, varying in color and texture, and each layer representing a different value. In describing these different layers I desire to be particular in the description of a few, as showing peculiar and unaccountable phenomena in nature....”

(This section continues with discussion on the following subjects. To read those sections, first go to the location and then find the entry title. (1) Sheldons & Slason’s Quarry, (2) Sutherland Falls Quarry, and (3) Eureka Marble Quarry.)

The Marble Business.

“The first opening for marble was made in West Rutland in 1838, and promised success for a while, but its importance was eclipsed when in 1843 William F. Barnes, the pioneer in the marble business, commenced work upon the rich deposit of what now belongs to the Rutland Marble Company. The Sutherland Falls quarry was opened about the year 1830, and has been worked at intervals ever since until to-day. Although it boasts of no white marble, it ranks in importance second to none in Rutland county. This is owing to the fact that colored marbles are more durable and more sought by purchasers for monumental purposes than the white marble, so much used in its early history. But the use of No. 1 and statuary marbles has demonstrated the fact that their composition is unsuited for external uses; the experience of years proving more to the practical mind than science could possibly accomplish.

“There are twenty marble mills in Rutland county, in which are 200 gangs of saws, each gang having about 22 saws. About 50 gangs in different mills are at present idle from various causes, the most apparent one being the want of capital. Some of these gangs are idle for want of paying marble to saw, the deposit upon which they are located being worthless as a practical enterprise. These saws, in the most approved mills, will pass through a block of marble, free from flint, 4x6 feet, at the rate of one inch and a half to the hour, each gang sawing 220 feet in twelve hours, and the 150 gangs now in operation sawing 33,000 feet of marble every twelve hours, making an aggregate annual production of saws marble in Rutland county of 9,900,000 feet. It is estimated by statistics and careful observation that of this marble there are $1,500,000 worth sold in the markets each year.

“It will be difficult to give anything more than a comparative value of the different marbles quarried in Rutland, being, as an article of merchandise, subject to advance and decline. But there is an intrinsic and standard value attached to marble of some grades which the fluctuations of markets cannot affect, or the niggard necessity of a ten per cent. loan destroy. Like the gold dug from the mountain side, it has a standard value, and when the capitalist can secure a deposit largely composed of statuary No. 1 and average marbles, he can invest with perfect safety, and success will certainly crown and repay confidence so bestowed. But that quarry which is composed of three quarters No. 3 marble, a thin layer of statuary, and a little No. 1, is dangerous to both the pockets and the morals of any man who is bold enough to engage therewith. It will prove a pecuniary mill-stone carrying him to the very depths of bankruptcy.

“In the early history of marble quarrying the process was to blast from the bed with small charges of powder, but the folly of this was soon ascertained, and a better and the present way of quarrying was discovered. The early process destroyed a great deal of marble, and after a great expense in opening a quarry, it was natural that a better way should be sought out. The present mode, you are aware, is to cut channels with drills sharpened for the purpose, about two inches in width, and at any desired length or angle. The marble is raised from the beds with ‘half-winds’ and wedges placed in holes drilled for the purpose. It is considered a day’s work to cut one and a half feet of such a channel, although experienced men can cut double that amount.

“The cost of quarrying marble, of course, depends much upon the texture of it; but in most deposits can be quarried at an expense of seventy-five cents per cubic foot. It is usually more expensive to quarry the poorer grades, as more flint and foreign substances enter into their composition. Contracts for quarrying have been made as low as fifty cents per cubic foot, but this is regarded as below the actual expense of quarrying. With an expense of seventy-five cents for quarrying, and the same amount for sawing, and an additional expense for selling, we have an aggregate cost of $1.75 for the manufacturing of marble and placing it in market. There is at least one-half of the marble quarried that is sold for a less sum than $1.75; much of it is sold for $1.00 per cubic foot.

“Therefore the theory that poor grades of marble will not pay for manufacturing, and are impolitic to open, much more to work such quarries. This theory also shows the net profit of quarrying good marble - a large per cent. being the net proceeds thereof. It has long been a subject of contemplation why sound marble is more readily found in Rutland county than in Addison and Chittenden counties. The theory advanced by some is that in the ‘drift period,’ the debris and loose rock were washed from the higher places and mountain sides of Rutland to the lower counties of Addison and Chittenden; certain it is that no successful openings have been found north of Brandon. This theory, if correct, will also account for the solid marble of Danby and Dorset. The theory may yet be demonstrated that when a great depth, perhaps fifty or seventy-five feet, has been reached, sound marble may be obtained in these counties, but I divine the reason not to have existed upon the surface, but within the earth. It will be noticed that the marble in Middlebury, Shelburne and Hinesburgh are all of a similar cast - the white marble being very fine in texture, but rarely sound - when the colored marbles in the same deposits are generally sound.

“These reasons, with the other peculiarities and phenomena, are sufficient to guarantee the fact that marble was placed in its present position by the result of plutonic action, although some of the layers in their composition and position would warrant and suggest aqueous deposits. But this last theory could not in any way account for the present condition of the highly crystallized marbles, like the statuary and No. 1 marbles.

“Stubborn facts, as revealed in the history of the marble business of Vermont, are sufficient to warrant just conclusions, without resorting to theories not fully based upon practical knowledge.*

“* It has been the object of this paper to give the extent of the deposits enumerated, and not different quarries, but I have mentioned some quarries as representing different features of the same deposit, nor is time and means at hand to give in detail a description of all the quarries in Rutland county. I mention the quarry of Sheldons & Slason as they have developed the greatest number of layers of any firm in West Rutland, and a description of their ‘new opening’ describes all the openings upon this deposit, consisting of the quarries of Parker, Gilson & Denny, Rutland Marble Company, Sherman, Adams & Williams, and the Manhattan Marble Co. I mentioned the Sutherland Falls marble quarry as representing a new deposit of marble of a different nature and color, also the Columbian Marble Co., and the Eureka Marble Co., as quarries upon this deposit but varying in color.”

-

Rutland & West

Rutland, Rutland County, Vermont – “Vermont

Marble,” in The

Youth’s Companion, by Priscilla Leonard, New England

Edition, July 14, 1898, pp. III.

Rutland & West

Rutland, Rutland County, Vermont – “Vermont

Marble,” in The

Youth’s Companion, by Priscilla Leonard, New England

Edition, July 14, 1898, pp. III.

Cutting Marble, from “Vermont Marble,” in The Youth’s Companion, by Priscilla Leonard, New England Edition, July 14, 1898, pp. III.

Vermont Marble.

“When Hiram Powers, the great American sculptor, had need of a block of perfect marble, he sent for it to his native state of Vermont, though he was then resident and working near the famous marble quarries of Carrara, in Italy. From this Vermont block he carved his finest statue, ‘The Greek Slave,’ which showed the American marble to be as flawless, as fine in grain, as pure and uniform in color and tone, and altogether as perfect as the best Italian marble known to sculptors.

“The quarries from which ‘The Greek Slave’ came are still being worked, and show no sign of exhaustion. All through the valleys about Rutland, in the western part of the state, marble underlies the ground in endless variety. – the pure white statuary marble, the chocolate, the green and white, the gray, the blue-veined – and some of these take a marvelous polish. Talk about ‘marble halls!’ The very sidewalks of West Rutland, as well as its halls, are of marble, and the foundations of the quarrymen’s cottages gleam white against the green hillsides.

“Stores, churches and mills are built of the omnipresent stone, and grayish-white heaps of it lie everywhere – huge blocks, rough slabs and broken fragments carelessly piled among the great derricks and beside the dusty roads and tracks. The very drain that the loquacious Italian gang were repairing as we passed them on our road to the quarry was being made out of marble.

“The first view of a flock of sheep by one who has imagined sheep to be creatures of snow-white fleeces, is less shocking than the first view of a marble quarry to one who has expected to see a thing of glittering beauty. From the rough railing that fences round a great hole in the earth, one looks down into a yawning depth of dirty gray, marked here and there by wide streaks and splashes of black upon the massive hewn sides. These sides are marked off in lines of drilling about seven feet apart, each line showing where a level has been worked over and taken out.

“From the rubbish-strewn bottom, three hundred and sixty feet below, – this is in the West Rutland quarries, – wide, yawning galleries, hundreds of feet long, stretch out, dark and disused, under the hill. Half-way down the quarry is the level now being worked, and to that the visitor can descend by wooden stairs, clinging to the walls, as shown in the illustration.

“After having descended – what a noise! As one scrambles down the last stair and wades over the sticky floor – for water used in the drilling forms a glutinous paste with the marble dust, and collects in sloppy white puddles everywhere – the din of the drills strikes full upon the ear, incessant and deafening.

“The level stretches away like a large gray cavern, low-roofed and vast. The heat of the steam, under the lowering curve of the rough-hewn ceiling, is pervading and oppressive. The bending arch of marble above is black with the accumulated soot from the engines that work drills and saws. A mist of steam and smoke fills the air, through which the electric lights upon each drill gleam weirdly and are reflected in the whitish pools of the floor. The throbbing thud of the steel as it strikes the marble, and the continual jar of the heavy machinery as the drill moves on, jerkily, over its appointed track, fill one’s ears to the entire exclusion of any other sound, and make speech impossible, so that the processes have to be explained to one in pantomime by the obliging foreman.

“Each drilling-machine – there are half a dozen or so on the level – has a movable iron track, the ordinary width of which is about six and a half feet. Upon this it runs, while the steel drills on each side of it, rising and falling incessantly, pierce the marble steadily as they are moved along. When the machine has run forward to the limit of its track, it moves backward again, the drills piercing the deeper at each journey.

“When the marble has been thus drilled six feet and a half deep, the rails are taken up and replaced across the level, and the machines then proceed to cut new grooves at right angles to the former ones. When the level has been entirely cut up into squares by this simple method, wedges are driven beneath, beginning at the open side of the level, and the marble separated into great cubes, each weighing ten or twelve tons, which are then swung out by the derricks and placed in readiness for the mills. Of course, when a statuary block is wanted, it can be cut out to order, of any desired size.

“The most notable thing about the marble-mills, or ‘sheds,’ is the simplicity of their processes. Water and sand are the principal reliance of the marble-worker. The great saws for cutting the blocks in slabs, for instance, are nothing but that pieces of metal, with no teeth and no carefully sharpened edge. To and fro they swing, a dozen or so of them to each block, hour after hour, through the marble, slowly and steadily, while a continual stream of sand and water pours over them, doing the real cutting by its wearing action between the saw and the groove. The cutting is very slow, as, indeed, are all the processes.

“Perhaps the briskest machine is a ‘beveller’ that shapes off the edges of the slabs as they have been sawn and partly polished. The polishing is all done with either sand or pumice-stone and water, sometimes under a leather pad, sometimes on a revolving table, but always slowly and thoroughly. And the last polish is given with the skin of the human hand! No tool or machine, it seems, will give quite the delicate high polish that the workman’s bare hand can impart.

“The great veined slabs, after they are finished, are wonderfully beautiful. Some go to line the corridors of great buildings, or to ornament their façades; some are for mantels and tables, and some even for floors. One rich man in New York has a bathroom built all of the exquisite green and white marble – walls, ceiling and floor, and a deep bath sunken in the floor at one end, with silver rail and faucets.

“It seems a long way from the soot and sloppiness and noise of the quarry to such luxury as that, doesn’t it? But polish, literally or figuratively speaking, carries its possessor a long way toward ornamental existence.

“Priscilla Leonard.”

- Rutland, Vermont - Albertson Marble Quarry

Albertson Marble Quarry - Also see: West Rutland (east side), Vermont - Albertson Marble Quarry in the “ West Rutland, Vermont ” section.

- Rutland, Vermont – Albertson Marble Co. (Marble

dealer) (The following information is from an advertisement in Stone:

An Illustrated Magazine, Vol. XI, No. 6, November, 1895,

Stone Publishing Co., New York, pp. XLiv.)

Albertson Marble Co., Rutland, Vt.

Esperanza Blue Marble,

- Rutland, Vermont – the Columbian Marble Quarry

Co. (The following information is from the section "Stone

Trade Notes" in Stone: An Illustrated Magazine Devoted

to Stone, Marble, Granite, Slate, Cement, Contracting and Building,

Vol. XXIV, No.1, January, 1902, Stone Publishing Co., New York,

pp. 66 and 68.)

The marble mills which are being built by the F. R. Patch Manufacturing company, for the Columbian Marble Quarry Co. at Rutland, Vermont, are nearing completion.

There was a brief strike of the employees of the Columbian Marble Quarrying Company, of Rutland, Vt., owing to the objection of the men to the foreman of the polishing shop. The foreman was removed, and the men returned to work.

- Rutland (between Sutherland Falls & Rutland), Vermont

- the Eureka Marble Quarry circa 1872. (You will

find the complete history of the Rutland County Marble Quarries

circa 1872 in the entry entitled: “Rutland County, Vermont

- Rutland County Marble, with a History of the Marble Industry

of Vermont up through 1872 above.”)

The following excerpt is from a paper from the First Annual Report of the Vermont State Board of Agriculture, Manufactures and Mining, for The Year 1872, by Peter Collier, Secretary of the Board Montpelier, J. & J. M., Poland’s Steam Printing Establishment, 1872, “Rutland County Marble, with a History of the Marble Industry of Vermont, and a Statement of Comparative Value,” An address delivered before the State Board of Agriculture, &C., at Burlington, Jan. 24, 1872, By J. E. Manley, Esq., of West Rutland. (pp. 656-666).

Eureka Marble Quarry.

“But I should do injustice did I not mention the opening at Federal Bridge, upon the east bank of Otter Creek, midway between Sutherland Falls and Rutland. The marble from this opening resembles very closely the Italian, and also the No. 1 of the Sutherland Falls marble, is fine and of a variegated appearance. The owners of this new and apparently valuable opening have recently built a new mill, and everything promises success.”

- Rutland, Vermont – F. R. Patch Manufacturing Co. – Stone

Working Machinery (The following information is from

an advertisement in Stone: An Illustrated Magazine,

Vol. XI, No. 6, November, 1895, Stone Publishing Co., New York,

pp. XLi.)

F. R. Patch Mfg. Co., Rutland, Vermont

Stone Working Machinery Of Every Description

Stone Planers a Specialty.

Gang Saws, Rubbing Beds of All Sizes, Slate Saws, Lathes, Etc.- Rutland, Vermont – F. R. Patch Manufacturing

Co. (The following advertisement is from The

Monumental News, August, 1895, Vol. 7, No. 8, Chicago,

Illinois, pp. 511

F. R. Patch Manufacturing Co., Rutland, Vt.

Stone Working Machinery a specialty.

Stone Mill Builders and Contractors. Gang Saws, Derricks, Steam Hoists, etc. Rubbing Beds, Polishing, Planing and Moulding Machines for Marble and Granite. Circular Saws for Stone, Marble and Slate. Correspond with us regarding anything in the way of Stone Working Machinery. Mention the Monumental News.

- Rutland, Vermont - the F. R. Patch Manufacturing

Co.. The following information is from The

Monumental News, August, 1895, Vol. 7, No. 8, Chicago,

Illinois, pp. 520.

“The F. R. Patch Manufacturing Co. of Rutland, Vt., are building a 50 horse power hoisting machine for the Vermont Marble Co.’s No. 4 quarry at West Rutland.”

- Rutland, Vermont – F. R. Patch Manufacturing

Co. (The following information is from an advertisement

in Stone: An Illustrated Magazine Devoted to Stone,

Marble, Granite, Slate, Cement, Contracting and Building,

Vol. XXIV, No. 1, January, 1902, Stone Publishing Co.,

New York, pp. 79.)

F. R. Patch Mfg. Co., Rutland, Vt., U.S.A.

True Circles

The Only Planer in the World that will Cut True Circles.

Write us and we will tell you about it.

Gang Saws, Planers of Every Description, Rubbing Beds,

Soft Stone Saws, Jenny Lind Polishers, Derricks, Lathes, Etc.

Chicago Office, 19 & 21 S. Canal St., Tel. Main 5028

V. B. Macomber, Agent.

Baltimore Office, 110 S. Howard St.,

Telephone No. 2020.

Henry H. Meyer, Agent. -

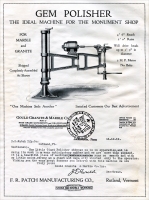

Rutland, Vermont – F. R. Patch Manufacturing Company (Advertisement from Granite Marble & Bronze, Vol. 30, No. 10, October 1920, pp. 59)

F. R. Patch Manufacturing Co., Rutland, Vermont

Specialists in Stone and Marble Working – MachineryGem Polisher: The ideal machine for the monument shop for marble and granite.

- Rutland, Vermont – F. R. Patch Manufacturing

Co. (The following advertisement is from The

Monumental News, August, 1895, Vol. 7, No. 8, Chicago,

Illinois, pp. 511

- Rutland, Vermont - the Foley Marble Prospect (from Commercial

Marbles of Western Vermont, Bulletin 521, by T. Nelson

Dale, United States Geological Survey, Government Printing Office,

Washington, D. C., 1912.)

“The Foley prospect is about three-fourths of a mile west of the southeast corner of Rutland Township. The outcrop extends here and there, it is reported, into the township of Clarendon, toward a well-known bed of kaolin on the north bank of Cold River. Prospective operator, Edward H. Foley, 147 South Main Street, Rutland, Vt.

“The beds, to judge from their geographic position, probably belong not far from the basal dolomite.

“The marble (specimen D, XXXI, 86, a, polished) consists of alternating beds of very light gray calcite marble from 0.2 to 0.5 inch wide, alternating with irregular beds of very dark gray graphitic untwinned dolomite from 0.04 to 0.1 inch wide, both sets being most intricately plicated together. The calcitic parts polish well but the dolomitic not at all. Associated with these beds are also whitish calcitic marbles more faintly mottled with graphitic dolomite.

“The beds are reported to lie in vertical position.”

- Rutland, Vermont – Frenier & Le Blanc (The

following information is from an advertisement in Stone: An

Illustrated Magazine, Vol. XI, No. 6, November, 1895, Stone

Publishing Co., New York, pp. 566.)

Frenier & Le Blanc, U.S. Agents

Rutland, Vermont

Pearson's "Krushite" For Rapid Sawing and PolishingGranite, Stone and Marble. This material is largely used in Scotland, Sweden, Norway and Belgium on the hardest granites; also in Europe generally for sandstone, limestone, and other ordinary building stones, and in Italy, Switzerland and Belgium, on marble.

It combines toughness with hardness, and cannot be fractured under the saw blades or rubbers. It is despatched (sic) to parts of England, Scotland and Foreign countries where there it is preferred on account of its greater efficiency and durability. It is perfectly clean, evenly graded in standard sizes, and cheaper and more economical than any other material.

- Rutland, Vermont – Frenier & Son (Sand Feed

Pump) (The following information is from an advertisement

in Stone: An Illustrated Magazine Devoted to Stone, Marble,

Granite, Slate, Cement, Contracting and Building, Vol.

XXIV, No. 1, January, 1902, Stone Publishing Co., New York,

pp. 87.)

Frenier & Son, Rutland, Vt.

Frenier's Sand Pump. For Feeding Sand, Steel or Shot for Sawing Stone. Saws faster, uses less sand and water and requires less power and repairs than any other. Pays for itself in six months. Send for full description and prices.

- Rutland, Vermont – Frenier & Son (The

following information is from an advertisement in Stone: An

Illustrated Magazine, Vol. XLVI, No. 3, March, 1925, Stone

Publishing Co., New York, pp. 178.)

Frenier & Son, Rutland, Vermont

Frenier's Sand Pump

For Feeding Sand, Steel or Shot for Sawing Stone

Saws faster, uses less sand and water and requires less power and repairs than

any other. Runs only 20 revolutions per minute. Pays for itself in six months.

Used by the Best and Largest mills. Send for full description and prices. - Rutland County, Vermont – Hilltop Slate – Slate Quarries. In 1995 this company operated two slate quarries in Rutland County. At that time the company headquarters was located at Mid Granville, New York. (From United States Geological Survey, Mineral Industries Surveys - Directory of Principal Dimension Stone Producers in the United States in 1995, prepared in January 1997.)

- Rutland, Vermont – Lincoln Iron Works – Stone-Working

Machinery (The following information is from an advertisement

in Stone: An Illustrated Magazine, Vol. XI, No. 6,

November, 1895, Stone Publishing Co., New York, pp. xxxv.)

Lincoln Iron Works, Rutland, Vermont.

Stone-Working Machinery

Planers, Gang Saws, Rubbing Beds, Derricks, Traveling Cranes, Hoisting Powers

All kinds of estimating promptly attended to.

New York Office: 182 Front Street.- Rutland, Vermont – Lincoln Iron Works (Advertisement from The Monumental News, Vol. XXI, No. 6, June 1909, pp. 450.

Do you want the best thing in polishing machines? The Granite City Improved?

Lincoln Iron Works, Rutland, Vermont

The Joshua Hendry Iron Works, 63 Fremont St., San Franicisco: Agents for California, Arizona, Oregon and Utah. Caldwell Brothers Co., 1014 First Ave., South, Seattle, Washington: Agents for the State of Washington.(photo caption in ad) “Granite City Improved Polishing Machine”

- Rutland, Vermont – Lincoln Iron Works (Advertisement from Stone, Vol. XXXVIII, No. 7, July 1917, pp. 380)

Lincoln Iron Works, Rutland, Vermont – Lincoln Stone Working Machinery

Stone Planing Machines, Thomson Patent Circular Planning Attachment, Lincoln Screw Gang Saw, Wardwell Channeling Machinery, Carborundum Machines, Polishing Machines, Rubbing Beds, and Special Stone Mill and Quarrying Machinery built to order.

- Rutland, Vermont – Lincoln Iron Works (Advertisement from The Monumental News, Vol. XXI, No. 6, June 1909, pp. 450.

-

Rutland, Vermont – Lincoln Iron Works (Advertisement from Granite Marble & Bronze, Vol. 30, No. 10, October 1920, pp. 62)

Lincoln Iron Works, Rutland, Vt. – Lincoln Stone Working Machinery

Our Polishing Machines have a recognized standard for quality and efficiency throughout the entire world, and we are building the machines in five different sizes to meet the various demands of the Marble and Granite Trade. All machines have the hollow or smooth box section arms, thus ensuring greatest rigidity without increasing the weight to be moved around.

Be sure to investigate Lincoln Polishers; they have many new features. One of the largest marble concerns in the world has more than sixty Granite City improved machines in their different plants.

Lincoln Gang Saw fitted with Thompson Parallel Motion Attachment is the most economical and fastest cutting gang saw for Granite, built exclusively by us. Ask for Catalogue G.

- Rutland, Vermont – The Producers' Marble Company (The following advertisement is from The Reporter: Devoted To The Interests of Marble and Granite Workers, Vol. XVII, No. 6, published by Nichols & Co., Chicago, Illinois, June, 1884, pp. 19.)

| F. R. Patch Manufacturing Co., Rutland, Vermont – Advertisement from Granite Marble & Bronze, Vol. 30, No. 10, October 1920, pp. 59. |  |

| Lincoln Iron Works, Rutland, Vermont – Advertisement from Stone, Vol. XXXVIII, No. 7, July 1917, pp. 380 |  |

| Lincoln Iron Works, Rutland, Vt. – Advertisement from Granite Marble & Bronze, Vol. 30, No. 10, October 1920, pp. 62. (photo caption in advertisement) “Rutland Polishing Machine Radial Swing 7’- 2”. |  |

- Rutland County, Vermont – Quarry Slate Industries Inc. Slate Quarry. In 1995 this company operated a slate quarry in Rutland. At that time the company headquarters was located in Poultney, Vermont. (From United States Geological Survey, Mineral Industries Surveys - Directory of Principal Dimension Stone Producers in the United States in 1995, prepared in January 1997.)

-

Rutland, Vermont – the Steam Stone Cutter Company (Wardwell Machines Advertisement, circa 1893) – Circular Descriptive of the Wardwell Stone Channeling and Quarrying Machines, Issued by the Steam Stone Cutter Company, Proprietors of Patents and Sole Manufacturers, Rutland, Vermont, 1893, 16 pp.

The catalog begins:

“The largely increasing demand for stone for building and other purposes, calls for the introduction of labor-saving devices, which, while increasing the supply, lowers the cost of production. To this class belong the machines herewith illustrated and which are extensively used for quarrying throughout the country.”

- Rutland, Vermont – the Steam Stone Cutter Company (The following information is from an advertisement in Stone: An Illustrated Magazine, Vol. XI, No. 6, November, 1895, Stone Publishing Co., New York, pp. iii.)

- Rutland, Vermont – the Steam Stone Cutter Company (The following information is from an advertisement in Stone: An Illustrated Magazine Devoted to Stone, Marble, Granite, Slate, Cement, Contracting and Building, Vol. XXIV, No.1, January, 1902, Stone Publishing Co., New York, pp. 81.)

- Rutland, Vermont – the True Blue Marble Co. Quarry

and Mill (The following information is from an advertisement

in Stone: An Illustrated Magazine, Vol. XI, No. 6,

November, 1895, Stone Publishing Co., New York, pp. vii.)

True Blue Marble Co., Office, Quarry and Mill, Rutland, Vermont.

J. W. Cramton, President.

Geo. E. Royce, Treasurer and Manager.

Geo. B. Royce, Secretary.

Producers of the Finest Grades of Dark and Extra Dark Veined, Dark and Extra Dark Mottled Blue Marble, in Block, Sawed and Finished Stock. - Rutland, Vermont – Vermont Marble Company History & Sketches – Marble in New England, Newcomen Address by Redfield Proctor, President Vermont Marble Company, The Newcomen Society of England – American Branch, Printed in U.S. A. The Barta Press (no date of publication – probably mid-1900s)

The Producers' Marble Company

Representing the joint stock carried on hand by

The Vermont Marble Co., Sheldon & Sons,

Gilson & Woodfin, Ripley Sons, The Dorset Marble Co.,

With Central Office At Rutland, VT.

Redfield Proctor, Pres., John A. Sheldon, Vice Pres.

E. P. Gilson, Sec. and Treas., D. K. Hall, Manager

With Branch Yards at:

Boston, Mass., 161 Causeway St., Jno. D. Allan, Manager

New York City, 398 to 403 South St., Jonas Clark, Manager

Philadelphia, PA., 2400 Chestnut St., Samuel Williams, Manager

Toledo, Ohio, 4, 6, 8, & 10 Lafayette St., H. D. Pierce, Manager

Chicago, ILL., East End Michigan St., Thomas A. Hall, Manager

St. Louis, MO., Corner 11th and Spruce Sts., E. H. Bradbury, Manager

San Francisco, Cal., 112 Montgomery Avenue, G. Landon, Jr. Manager

Offers to the Trade opportunities of selection through its manager and agents from over One Million of Feet of Marble Carried constantly in stock in Rutland, and over Half A Million of Feet In regular stock in its branch yards.

With these great advantages, it aims to guarantee Prompter Shipment than any one firm could give, Steam and Fair Prices and Uniform Grades, supplying all the Trade, who are in good commercial credit, with the utmost impartiality.

It does not in any way tend to interrupt the long and friendly relations of the old-established dealers with the respective companies composing the Producers' Marble Company.

On the contrary, any dealer having any preference as to the yard from which he wishes his marble selected, can so indicate or order direct; but for the convenience of the Central Office, all invoices will be sent out and collections made by it. Nor does the organization of this Company seek to interfere with the distribution of our marble by the old, well-tried and popular wholesale dealers now in existence, in whose success are heartily interested; but it facilitates the distribution of it, by opening up to every order, large and small, that comes in, either to Rutland or the Branches, the chances of careful matching and quick shipment from a vast Stock, larger than any one company could carry. The rapid multiplying of designs has so enormously increased the sizes and shapes in which our marble is wanted, that no one company could produce them except after moths of vexatious and damaging delay.

The marbles represented by this Company embrace all the sound white and blue marbles of West Rutland, all the Older and Most Standard of Vermont Marbles.

In conclusion, we promise, individually and collectively redoubled efforts to place our produce in your hands to your entire satisfaction. Thank you for the favors of the past, and soliciting a renewal of them for the coming year, we remain, your obedient servants, The Producers' Marble Co.

|

|

“No. 2, Double Gang Machine, Price $1,600” |

“Plan view of quarry floors showing process of quarrying with the Wardwell Channeling Machine” |

Steam Stone Cutter Company

J. W. Chamton, President

Geo. E. Royce, Treasurer - H. O. Carpenter, SecretarySteam Stone Channeling and Quarrying Machine

The original and first Stone-Channeling machine ever invented. Will pay for itself in a short time in reduced

cost of getting out stone. Has no equal for efficiency and economy of operation.Pronounced by Those Who Have Used It the Best Machine for the Purpose in the World.

Steam Stone Cutter Company, Rutland, VT.

J. W. Cramton, President.

Geo. E. Royce, Treasurer.

Edmund W. Royce, Secretary.The Wardwell Steam Stone Channeling and Quarry Machine

The original and first Stone-Channeling machine ever invented. Will pay

for itself in a short time in the reduced cost of getting out stone. Has no

equal of efficiency and economy of operation.Pronounced by those who have used it the Best Machine for the purpose in the world.

Send for Illustrated Catalogue, with full descriptions, and letters from parties now using the machines.

|

|

|

Front cover of in Marble in New England |

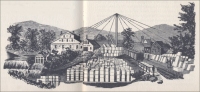

Rutland Mable Co. Center Rutland Mill, in Marble in New England |

Rutland Marble Co., Quarries & Mills, in Marble in New England |

|

|

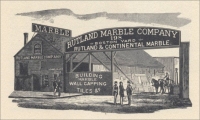

Rutland Marble Co. Continental Mills - Turned Work & Tiles, in Marble in New England |

Rutland Marble Co. Rutland & Continental Marble, Boston Yard - Sketch in Marble in New England |

- Rutland County, Vermont – Vermont Quarries Company Marble Quarry. In 1995 this company operated two marble quarries in Rutland. At that time the company headquarters was located in Proctor, Vermont.. (From United States Geological Survey, Mineral Industries Surveys - Directory of Principal Dimension Stone Producers in the United States in 1995, prepared in January 1997.)

- Rutland County, Vermont – Vermont Structural Slate Company Slate Quarry. In 1995 this company operated three slate quarries in Rutland. At that time the company headquarters was located in Proctor, Vermont. (From United States Geological Survey, Mineral Industries Surveys - Directory of Principal Dimension Stone Producers in the United States in 1995, prepared in January 1997.)

Commercial use of material within this site is strictly prohibited. It is not to be captured, reworked, and placed inside another web site ©. All rights reserved. Peggy B. and George (Pat) Perazzo.