Sandstone in General - Varieties of Sandstone.

“The term ‘sandstone’ is applied to a rock composed of mineral grains smaller than pebbles, cemented together more or less firmly.

“‘Conglomerate’ is the name given to a rock composed of pebbles, or pebbles and bowlders, of various sizes cemented together. If the pebbles are large and well rounded the rock is sometimes called ‘pudding stone.’

“Although the term ‘sandstone’ includes all varieties, certain specific terms are applied to types characterized by particular compositions, colors, or uses. ‘Quartzite’ is a variety in which the individual grains are so firmly cemented together with quartz that the rock will fracture as easily through the grains as through the cement; ‘ferruginous sandstone’ is one rich in iron as cementing material, or as grains, or both; ‘micaceous sandstone’ is one in which mica is prominent; ‘arkose’ is a feldspathic or granitic sandstone composed of angular grains; ‘calcareous sandstone’ is one containing considerable calcium carbonate; and ‘argillaceous sandstone’ is one containing considerable clay.

“The term ‘flagstone’ is used for a rock that splits readily into sheets suitable for flagging; ‘freestone’ for rock that can be cut or carved readily, and with equal ease in all directions; and ‘ganister,’ in the United States, for sandstone suitable for the manufacture of Refractories. Others are named from their characteristic colors such as ‘bluestone,’ ‘redstone,’ or ‘brownstone.’

Composition of Sandstone.

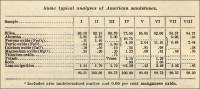

“As a rule the majority, and in some samples nearly all, of the grains that form sandstone are of quartz. Rarely, a sandstone is found consisting of grains of limestone. Many of the quartzose sandstones contain grains of various minerals such as feldspar, garnet, magnetite, zircon, and mica. Muscovite or white mica is common in sandstone. Iron oxide, calcium or magnesium carbonates, and clay are other common accessory constituents. calcareous sandstones are intermediate types between sandstone and limestone, and argillaceous sandstones are intermediate between sandstone and shale. The calcareous and argillaceous types are little quarried. In the table following are given some typical analyses of sandstones:

Notes on Samples.

- Light-gray sandstone, Berea, Ohio; analyst, N. W. Lord.

- Sandstone, Cleveland Stone Co., Quarry No. 6, Amherst, Ohio; analyst, D. J. Demorest.

- Sandstone, Fulton, Ohio; analyst D. J. Demorest.

- Bluestone, Oxnard, N.Y.; analyst, W. E. Gifford.

- Salmon-red sandstone, Glencoe, Colo.*

- Sandstone, Rockville, Mo.*

- Sandstone, Stony Point, Mich.; analyst, F. W. Clarke.

- Red sandstone, Portage Lake, Mich.*

(* Page 6 footnote: Quoted by G. P. Merrill, Stones for building and decoration. 3d ed., 1910, p. 516.)

“The presence of alumina, together with potassium or sodium, or both, indicates that feldspars are probably present. Alumina without the alkalies indicates the presence of clay. A calcium or magnesium content indicates that the carbonates of calcium and magnesium form cementing material between the grains of sand, except where sufficient plagioclase, biotite, or hornblende are present in the rock to account for these constituents. Analyses V and VIII indicate the comparatively small percentage of iron oxides that can cause deep coloration....”

Color.

“The color of a sandstone is governed by its composition. The more important coloring ingredients are the iron compounds. A white or other light color that persists after exposure to oxidation indicates their absence. Brown, reddish, or yellowish colors denote the presence of ferric oxides, the more common forms being hematite (Fe2O3) giving a red color or limonite (2Fe2O33H2O) giving yellow to brown colors. Gray or bluish shades may be due to the presence of iron carbonate or grains of hornblende or chlorite. Black carbonaceous matter is rarely disseminated uniformly throughout the rock mass, and therefore has little or no effect on the color of the rock as a whole, but occurs rather in the form of black streaks or spots.

“Permanence of color is a desirable quality in structural stone, although a uniform change in color may not detract from its appearance. The deeper shades of red, brown, or buff are usually permanent, because they are due to the presence of the stable iron oxides. Blue or gray sandstone quarried from the lower ledges of a deposit, are, however, commonly subject to change in color. If ferrous sulphides or carbonates are present, weathering tends to produce a buff or reddish color by oxidation of the ferrous compounds to more stable forms. On this account the upper beds of some sandstone deposits may be buff, whereas the lower beds are gray or blue-gray, the latter being the unstable colors.

“Although uniformity in the distribution of color is to be desired for most structural purposes, rocks having streaks or bands of color may in some places give very attractive effects for interior decoration. Blocks that would at one time have been thrown on the waste heap on account of nonuniformity of color distribution are now being utilized to some extent for ornamental building....”

Structural Features of Sandstones - Beds.

“As described in the discussion of origin,* sandstones are laid down originally as sands in beds or layers. In some deposits there are open planes of separation at intervals of several inches or several feet. Such planes are usually due to marked changes in the process of sedimentation. Commonly a layer of shale or clay material intervenes between the sandstone beds. In other deposits, possibly on account of a pause in, and subsequent resumption of the process of deposition, the later bed may show no change in composition from the earlier, but there may be merely a lack of coherence between the beds, which are separated only by a smooth surface. Some open bedding planes are flat and smooth; others are wavy and uneven. In some deposits open-bed seams are continuous over wide areas; other seams when traced for short distances may be found to close up. Typical open-bedded sandstone are those of Berea and McDermott, Ohio; Farmer, Ky.; Potsdam, N. Y.; and Kettle River, Minn. The beds may be horizontal or tilted. As sands are deposited near shore, where the sea floor commonly inclines at a low angle, sandstone beds may exhibit a moderate dip even though undisturbed; others are tilted at various angles by earth movements.

(* Please note that the section on the origin of sandstones is not included in this document.)

“Other sandstone deposits are unbroken throughout a vertical extent of many feet, or may have scattered horizontal breaks that are continuous for short distances only. When such deposits were formed, the deposition was clearly uninterrupted, permitting a subsequent uniform adhesion of grains at all points. The extensive deposits near Amherst, Ohio, are of this type.

“What is known as crossbedding is common in sandstone. In such stones certain of the lines that mark planes of sedimentation cross the chief beds obliquely. Swirling eddies or currents in the water in which the sand was originally deposited probably account for such an arrangement. Ripple marks and worm borings are also common....”

The Uses of Sandstone.

“The various uses for which quarried sandstone may be employed are outlined below.

Use in Buildings.

“Sandstone is used widely for both exterior and interior building. Its homogeneity of composition and resistance to the solvent action of rain water makes it especially useful for exterior work. It may be sawed or cut for building blocks either as even-course stone or broken ashlar; also for the steps, caps, sills, water tables, coping, etc. It may be used for entire structures or for the trimming of structures made chiefly of brick or other material. For interior uses the more attractive types are in demand, those that have a color banding being employed by some architects Sandstones that are fine-grained and nonabsorptive may be used for lavatories. Many sandstones are well adapted for carving, and attractive designs carved from sandstone are to be seen in many buildings. Some sandstones, especially bluestone, are occasionally employed for floor tile.

“For rougher and less ornamental buildings, concrete has lately (circa 1917) been used extensively, and has therefore greatly limited the use of sandstone for such construction. Heavy blocks of sandstone or quartzite were once used extensively in bridges, and are yet used considerably for this purpose. The lower grades of sandstone are used for rubble or cellar stone. The term ‘rubble’ is applied to stones of various sizes, each of which has one good face; the term ‘cellar stone’ includes irregular small fragments also. Such stones are used chiefly for foundations of houses or other structures. Retaining walls are commonly built of rubble, though sometimes the better grades of cut stone are used. Large fragments containing many imperfections may be used as riprap for breakwaters or for protecting river banks.

“As quartz, the chief constituent of sandstone, is the most resistant to weathering of all common minerals, a well-cemented sandstone is among the most durable of all building stones; but sandstone has not by any means attained such extended use in the United States as its superior quality justifies.

Use For Grindstones.

“Sandstones, the grains of which are of proper size, shape, and uniformity, and are cemented in such manner as to grind steel rapidly and at the same time wear away with sufficient rapidity to prevent glazing of the surface, are used to make grindstones. In several quarries, especially those in Ohio, grindstones are manufactured in various sizes up to 7 feet 6 inches in diameter. In quarries of the finer-grained sandstones, smaller pieces may be utilized to make small grindstones for cutlery or scissor grinding, or for making hones or whetstones.

“The manufacture of pulp stones for grinding wood pulp, used in making paper, is of importance at some points on the upper Ohio River.

Use For Paving Stones.

“The manufacture of paving blocks is an important industry in many States. Sandstones suitable for paving must be well adapted for resisting abrasion. Only those in which the grains are firmly cemented together with siliceous cement; that is, the varieties known as quartzites, or sandstones which approach the quartzites in condition of cementation, may be used. Sandstones that have a good rift (easy bed splitting) and a good run (a second direction of easy splitting perpendicular to the bed) may be trimmed most readily, and therefore are a profitable source of paving stones.

“Sandstones with moderate cementation are, by some authorities, preferred to granite for paving, on account of the fact that they present a gritty surface, and also because they wear down at about the same rate as the cementing material in the cracks, and thus maintain a level surface, whereas granite blocks become smooth and rounded.

Use For Curbing.

“Curbstones may be of much softer material than paving stones, and although manufactured extensively in many quarries where paving stones are produced, they are also manufactured in large quantities in quarries where grindstones or building blocks are made. In the case of easy-splitting sandstone, curbing may be split out and hand trimmed at the quarry, while the more massive rocks are sawed into curbing.

Use For Flagging.

“Sandstone may be sawed into thin slabs for making sidewalks. Rock for sidewalks must have adequate strength, must be hard enough to resist the abrasion of the feet of pedestrians, and must be reasonably free of impurities that give rusty spots other stains when exposed to the weather. Bluestone is used extensively for walks, and has the advantage over most sandstones in that the reeds permit splitting into thin and uniform slabs of large size, thus saving the expense of sawing.

Use For Grave Vaults.

“The fine-grained, uniform sandstones of southern Ohio are used extensively for the manufacture of grave vaults. Each vault consists of six slabs of stone, two sides, two ends, bottom and cover. They are sawed 2 inches thick and are sand rubbed.

Uses of Crushed Sandstone.

Use as Aggregate in Concrete.

“Sandstone is used to some extent for concrete mixtures, but only the harder types are suitable. This is due partly to the fact that the softer types are weak and partly because the crushing of soft sandstone results in a large proportion, possibly one-quarter to one-third, of the mass crumbling away as sand. Crushed sandstone for concrete must compete with crushed limestone, trap, and granite, and also with gravel, and as a consequence its use is limited to certain localities where it is of excellent quality or where it is more accessible than other types of crushed rock. Quartzites supply crushed rock of good quality. Although they are extremely hard, they are brittle and therefore not as difficult to crush as might be expected. Crushed bluestone also gives good service in concrete mixtures.

Use on Roads.

“Most sandstones are too poor in cementing material to be useful for road surfaces, although certain quartzites are known to give good road surfaces for heavy traffic if the crushed stone is rolled wet. Some impure sandstones with considerable clay content have sufficient binding to make them serviceable for the finishing layer of roads or streets.

“One Pennsylvania company manufactures a mixture of asphalt and crushed quartzite, and sells it under the trade name of ‘ameisite’ for surfacing roads and streets.

“Crushed sandstone gives satisfactory service for road bases, as it provides good drainage. It is also used in the construction of concrete road-bases.

“The sand screenings from crushed stone may be utilized for mortar and concrete.

Use in Making Glass Sand.

“Very pure sandstones and quartzites are crushed to make glass and pottery. Small percentages of impurities may be removed by washing. In one glass-sand plant visited the rock is crushed and ground and is then washed with water six times. The necessary purity is indicated by the following analysis of glass sand ready for the market:

Analysis of commercial glass sand.

Constituent.

Silica - 99.85 per cent.

Alumina - 0.14 per cent.

Iron oxide - 0.012 per cent.

Lime - Trace.

“Inferior grades of sandstone are crushed for use on locomotives for sanding the tracks to prevent slipping of the wheels.

Use As Ganister.

“Quartzites containing only a small percentage of impurities may be crushed and ground for the manufacture of silica brick or other refractories. Such rock is termed ‘ganister’ in the United States. Coke ovens and furnaces of various types require silica brick for linings, and consequently there is a good demand for high-grade ganister.

Miscellaneous Uses.

“Sandstones that are fine-grained, dense, and impervious may be cut into thin slabs and used for constructing laundry tubs and similar plumbing fixtures. Few sandstones are suitable for this purpose. Slabs of sandstone are used also for electric switchboards and billiard tables. Sandstone that splits satisfactorily is sometimes used to make fence posts. Cubical blocks may serve as footings or under-pinnings for posts under heavy structures. Irregular masses are sold to fishermen to anchor nets. A limited amount of sandstone is used for monuments, though marble and granite are used much more widely for this purpose....”

Distribution by States.

Missouri.

“Carboniferous rocks in the northwestern half of Missouri constitute the chief source of quarryable stone. Rock exposure occur in Bates, Calloway, Clark, Henry, Howard, Johnson, Putnam, Saline, Schuyler, St. Clair, and Barton Counties. Sandstone of Cambrian and Lower Ordovician age is available in Barton, St. Genevieve, Franklin, and Hickory Counties. The friable St. Peter (Ordovician) sandstone is quarried for glass sand principally in Franklin, Jefferson, and St. Charles Counties.”

Statistics of Production.

“The total production of sandstone in the United States during 1914 was valued at a little more than $7,500,000. Table 4, compiled by Loughlin,* shows the relative amount of sandstone quarried as compared with other types of stone, and also the values of the different rocks devoted to various uses.”

(Page 129 footnote: Loughlin, G. F., The stone industry in 1914; Mineral Resources of U.S. for 1914, U.S. geol. survey, 1915, pt. 2, p. 826.)

| Table 4. Value of granite, basalt and related rocks (trap rock), sandstone, limestone, and marble sold for various purposes in 1913 and 1914, by kinds and uses. |  |

“The value of sandstones produced in the various States for the years 1910 to 1914 is shown in Table 5.*

(* Page 131 footnote a: See Loughlin, G. F., The stone industry in 1914; Mineral Resources of U.S. for 1914, U.S. geol. survey, 1915, pt. 2, p. 883.)

| Table 5. Value of sandstone (including quartzite and bluestone) produced and sold in the United States, 1910-1914, by States. |  |

“The value of sandstone produced by the various States in 1914, and classified by uses, is given in Table 6.**

(** Page 131 footnote b: See Loughlin, G. F., The stone industry in 1914; Mineral Resources of U.S. for 1914, U.S. geol. survey, 1915, pt. 2, p. 886.)

| Table 6. Value of the marketed production of sandstone (including quartzite and bluestone) in the United States in 1914, by States and uses. |  |