Chapter VI.

Cambro-Ordovician.

“The southern part of the State is largely underlain with a series of sandstone and magnesian limestone formations. Four different limestone and three different sandstone formations have been recognized as belonging to either the Cambrian or Ordovician, or perhaps to both, of these groups. The stone varies greatly in different parts of the several formations and nowhere have extensive quarries been opened. Much of the stone is adapted to use in buildings and other constructions, but very little of that which is durable can be cut and dressed satisfactorily.

“There are hundreds of places in the area underlain by these rocks from which small amounts of stone have been quarried. It would be practically impossible to locate and examine all these small quarries. It has therefore been our purpose chiefly to describe the stone as it occurs in some of the larger quarries, knowing that these descriptions apply very generally to the stone from the same horizons in other localities. The limestone quarries are described in the first part of the chapter and the sandstone quarries in the second part.*

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Piedmont area will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Part I. Dolomite (Limestone).

Bolivar.

“Two quarries, owned by John W. McReynolds and R. B. Vilas, are located in the vicinity of this city. The quarries are small, the stone being used exclusively to supply the local market. The stone is argillaceous, arenaceous dolomite, known as cotton rock, and pitted dolomite belonging to the Jefferson City formation. A great many other small quarries have been opened in this vicinity, but they are not being operated at present.”*

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Bolivar area will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Elston.

“Two small quarries are located two and one-half miles west of Elston and one-fourth of a mile north of the Missouri Pacific railway. These quarries are owned by Mr. Wm. Hitch and Mr. L. Wade.”*

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Elston area will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Farmington.

“The principal quarries near this city are operated by E. E. Hawn, Geo. Haller, J. B. Mueller & Son and the State Hospital for the Insane.”*

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Farmington area will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Jefferson City.

“All of the stone quarried in this vicinity belongs to what is known as the Jefferson City (Second Magnesian) limestone. This formation consists of two divisions, an upper which is chiefly cotton rock and a lower which is thickly bedded, pitted limestone. The cotton rock occurs in clean cut, well defined beds, which are easily quarried. It is fine grained, impure, light gray to buff colored, dolomitic limestone, which is easy to cut and dress, and looks well when placed in a wall. It has been used very extensively in Jefferson City and can be seen in the wall surrounding the penitentiary, in the retaining walls around the Governor’s mansion and in many of the buildings.

“The pitted dolomite occurs in thicker beds than the cotton rock contains irregular cavities filled or lined with fine sugary quartz. It has been used in a number of important buildings, although it is not quarried at present (circa 1904), except for the manufacture of quick lime. A three-foot bed occurs with the cotton rock in nearly all the quarries.

“The quarries located in this vicinity are owned and operated by John Dietz, John Kieselbach, Mueller & Geisler, The City, The State, Jacob Schmidt, Hagner and Lumis and L. D. Gordon. The stone in the last two is being used exclusively for the manufacture of quick lime and will be described in a subsequent report on ‘Lime and Cement.’”*

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Jefferson City area will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Rolla.

“The heavy bedded dolomite of the Jefferson City formation furnishes building stone for local use at this place. A number of quarries have been opened southwest of Rolla, which are worked intermittently as there is demand for the stone. The massive character of the masonry constructed from this stone is shown in Plate XIV.”

| Plate XIV. Dolomite (Jefferson City). Engineering Building, Rolla, Mo. (Basement constructed out of pitted dolomite.) |  |

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Rolla area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Part II. Sandstone.

Cole Camp.

“Two sandstone quarries, located about one-half mile south of this place, are operated respectively by Neff Bros. and John Chmelir. The stone is used chiefly for flagging, curbing and foundations in the immediate vicinity of Cole Camp.”

(Please Note: The section of this book that lists and describes the individual sandstone quarries located in the Cole Camp area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Union.

“Two quarries are operated near this city, the Kasmann quarry from which sandstone is obtained for local consumption and the St. Louis, Kansas City and Colorado railroad quarry which produces limestone used in the construction of culverts.”

(Please Note: The section of this book that lists and describes the individual sandstone quarries located in the Union area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Miscellaneous.

“The sandstone belonging to the Cambro-Ordovician is quarried in many places in the Ozark plateau region and is used for a variety of purposes, including buildings, sidewalks and culverts. In many localities it is hard and firm and occurs in thin beds which when quarried make excellent flagging for sidewalks. Although this stone when used in sidewalks may wear faster than cement concrete or brick, nevertheless it is more desirable for residence streets in the smaller cities and town of the State.

“At Pacific, Crystal City, Klondike, Gray’s Summit and other places the Pacific (St. Peters) sandstone is quarried in large quantities and sold to glass manufactories, foundries, and other consumers of high grade sand. It is exceptionally pure silica and is unexcelled for the manufacture of plate glass. It occurs in almost limitless quantities.”

Chapter VII.

Silurian and Known Ordovician.

“The rocks which are positively known to belong to these systems occur chiefly in the eastern part of the State, near the Mississippi river. The formations are chiefly limestone, in which occur several thin horizons of sandstone and shale. The active quarries are situated chiefly in the limestone and are located at Cape Girardeau, Bowling Green, Elsberry, Graysboro and Jackson. The following descriptions of the individual quarries give an excellent idea of the character of the stone in the different localities.”

Bowling Green.

“Several quarries have been opened in the Niagara limestone east of this city, but the only one which is now operated (circa 1904) is owned by Pl. L. Calwell and leased by J. F. Butters and Sons.”

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Bowling Green area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Cape Girardeau.

“The Silurian and Ordovician strata which comprise the geological formations of this county contain excellent stone for building and other constructional purposes. Shumard,* in his report on Cape Girardeau county, describes the occurrence of these strata. Mr. E. O. Ulrich of the United States Geological Survey, who is at present making extensive correlations of the Paleozoic strata throughout the central portions of the United States, has devoted considerable time to the geological succession in this State, along the Mississippi river from St. Louis south. As a result of this work Mr. Ulrich proposes using the following old and new names for the strata which occur over extensive areas in Cape Girardeau, Perry, Jefferson and St. Louis counties, and of which he will soon publish full descriptions in a paper on the Paleozoic Section in the Mississippi Valley.**

(Page 109, footnote 1: Information sent the author in a letter January 9, 1904.)

(** Page 109, footnote 2: Geol. Surv. of Missouri, 1855 to 1871, p. 260.)

“(1) The Birdsville formation embracing the shales and sandstones and thin limestones forming the upper part of the Chester group. Name derived from Birdsville, Livingston County, Kentucky.

“(2) The Tribune limestone which is proposed for the main limestone of the Chester group above the Cypress sandstone. It occupies the interval between the Birdsville above the Cypress sandstone (= Aux Vases sandstone) beneath. The typical locality is in Crittenden county, Kentucky.

“(3) The name Cypress sandstone having been proposed by Englemann in 1868 as a geographic designation for Swallow’s ‘Ferruginous sandstone,’ is adopted in preference to the latter name Aux Vases sandstone proposed by Keyes.

“(4) The Ste. Genevieve limestone is adopted from Shumard who distinguished the formation in 1860, and described it more fully in 1873. This formation proves to be more closely related to the Chester group than to the underlying St. Louis limestone.

“(5) The St. Louis Limestone is restricted to the typical fine grained and often cherty limestone formation to which the name was originally applied.

“(6) The name Spergen Hill limestone is adopted for the oölitic and granular limestone division of the group shown beneath the St. Louis limestone at the Meramec Highlands quarry and in the equivalent beds in the quarry at Wicks station. The Bedford stone in Indiana is derived from this formation.

“(7) The Warsaw limestones (and shales) occur at the base of the group at Meramec Highlands and extend northward from that point. This, together with the overlying Spergen Hill and St. Louis limestones are embraced in a group for which I propose the name Meramec group.

“(8) The Tullahoma formation (Safford) embraces the southern equivalents of the Osage and Kinderhook groups and may be recognized as far north as Ste. Genevieve, Missouri. North of this locality and the axis that here separated the basin at this time the two groups are readily distinguishable.

“(9) In the area about Glen Park and Sulphur Springs I have further distinguished, at the base of the Kinderhook and perhaps top of the Devonian, the Sulphur Springs formation. This formation is divisible into three members, a thin sandstone (about 10 feet) at the top to which the name Bushberg sandstone may be applied; beneath this a 1 to 5-foot bed of oölitic limestone, probably early Kinderhook in age, which may be called Glen Park (oölitic) limestone; and, finally, at the base a shale, 0-15 feet thick, either earliest Kinderhook or late Devonian in age, for which no subordinate designation is proposed.

“The formations from the Tullahoma to the Birdsville, both inclusive, are fully described in Mr. Ulrich’s report on the stratigraphic geology of the lead, zinc, and fluorspar deposits of Western Kentucky (in press).

“(10) The Grand Tower Limestone (Keyes, emend) contains the local representatives of the Hamilton and Onondaga limestones of the east.

“(11) The Clear Creek limestone or chert (Worthen) is the name to be applied to the extremely cherty limestone south of Wittenberg.

“(12) The Bailey limestone, from Shumard’s old locality, Bailey’s Landing, is proposed for the argillaceous limestones and shales containing the New Scotland Helderbergian faunas at Red Rock landing and above. This is practically equivalent to Safford’s Linden limestone of Tennessee.

“(13) The Bainbridge limestone embraces all the Silurian limestones beneath the preceding in the river bluffs for some miles above and below Bainbridge, Missouri. It also occurs above and below Thebes, Illinois; nearly equivalent to Safford’s Clifton limestone of Tennessee.

“(14) The name Girardeau limestone is adopted in this amended form for the limestone described by Shumard in 1873, as the Cape Girardeau limestone.

“(15) The Thebes formation embraces three subdivisions, viz.: a sandstone in the middle with a shale above and beneath. This is an extension of the term as used by Worthen.

“(16) The Kimmswick limestone is a new name referring to the more or less crystalline limestone being quarried at Graysboro, Cape Girardeau, Glen Park, Kimmswick and other localities in southeastern Missouri. The thin bed generally found at the top, 2 to 5 feet, holding the Fernville Richmond fauna, is not included.

“(17) The Plattin limestone is a new name proposed for the fine grained limestone formation between Kimmswick and the ‘First Magnesian’ and which has generally been called either Trenton or lower Trenton. It is the local but only partial equivalent for the rocks of the Stones River group in central Kentucky and Tennessee. The formation takes its name from Plattin Creek, Jefferson county, near the mouth of which it is well exposed.

“(18) The name Joachim limestone, proposed by Winslow, is adopted for the ‘First Magnesian.’

“In the vicinity of the city of Cape Girardeau three of these formations have been quarried. Just north of the city the Thebes sandstone, which caps the hills, was in former years quarried quite extensively. Near the northwest limits of the city the Kimmswick limestone has been quarried extensively for building stone and the manufacture of quicklime. At this locality the stone takes on much more the character of marble than at Kimmswick or Glen Park and is known locally as the ‘Cape Girardeau marble.’ It makes an excellent quicklime and is a durable and handsome building stone.

“South of the city quarries have been opened in the Plattin or Lower Trenton limestone, the stone being used for railroad ballast and buildings. Two quarries have been opened in the Bainbridge limestone, the stone being used chiefly for rip rap along the Mississippi river.

“The quarries in the vicinity of Cape Girardeau are operated by Burke Bros., Edward Hely, W. L. Kellebrew, Edward F. Regenhardt, J. C. Seiler, Wm. Regenhardt and the Cape Lime and Marble Co. The last named company is manufacturing quick lime from the Kimmswick limestone. This quarry will be described in a subsequent report on ‘Quick Lime and Cement.’”

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Cape Girardeau area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Graysboro.

“Two quarries are located near the Mississippi river at this place, both of which are operated to supply crushed stone used in the erection of the Thebes bridge, at Thebes, Illinois. The land on which the quarries is located is owned by Mr. Gray, to whom a royalty of 5 cents per cubic yard is paid.

“The stone is obtained from the Trenton-Kimmswick formation. It is a very coarsely crystalline, light gray limestone, similar to that at Ste. Genevieve. It is fossiliferous, contains an occasional fine suture joint and occurs in thick beds. It is very pure and makes an excellent grade of quicklime.

“The two quarries referred to above are operated respectively by C. McDonald & Co., and The Patterson Construction Co.”

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Graysboro area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Jackson.

“Several small quarries have been opened in the vicinity of this city to supply the local demand for building stone. The stone occurs in well stratified beds of moderate thickness. It is fine grained, compact, fossiliferous and brittle, and has a dark blue to black color. Weathering changes the color to a buff.

“Quarries have been opened in this vicinity by the following persons: John Kesterson, G. F. Green and T. McFarland, Edward Hendricks, Levi Hurst and W. H. Amnette.”

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Jackson area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Chapter VIII.

Mississippian (Sub-Carboniferous).

“This system, which consists chiefly of limestone, has a wide distribution in the southwestern, west central and northeastern parts of the State. The stone is chiefly a white or grayish colored, coarsely crystalline limestone. It is in this formation that the Carthage quarries are located. The following are detailed descriptions of the principal quarries located in this formation.”

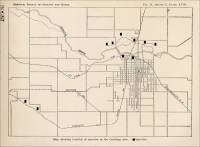

Carthage.

“The most extensive limestone quarries in Missouri are located at Carthage, the county seat of Jasper county. Although a comparatively new industry at this place, it has increased so rapidly that within eighteen years it has become the center of limestone production in this State. Today all of the quarries, with the exception of the Carthage Consolidated Co. and the Viernow and Meysenburg Lime and Cut Stone Co., are being worked to their utmost capacity and the Carthage limestone is fast becoming one of the most popular building materials in the middle west.

“With the exception of the Vernon and Lime-kiln quarries, all of those in the immediate vicinity of Carthage, are north of the city, along the escarpment just north of Spring river. The Veron (sic) and Lime-kiln quarries are located just south of Spring river near the northwest limits of the city. In addition to this, two quarries have been opened about five miles southwest of the City. All of these are included within the Carthage area and the stone which is produced is known as Carthage limestone. The following is a list of the quarries in this area:

Carthage Marble and White Lime Co.

Carthage Stone Co.

Carthage Quarry Co.

Viernow and Meysenburg Lime and Cut Stone Co.

Spring River White Lime Co.

Spring River Stone Co.

Carthage Building Stone Co.

Myers Stone Co.

Carthage Consolidated Quarry Co.

“For many years this stone was quarried by hand and used for foundations, caps and sills in buildings in and about Carthage. It was also used for bridge abutments on the Missouri Pacific railroad near the city. The first quarrying machinery was introduced about 1885, since which time the stone has gained an almost national reputation.

“Geologically, this limestone belongs to the Burlington division of the Mississippian or Lower Carboniferous. The formation obtained its name from Burlington, Iowa, where it is typically developed. The Mississippian outcrops on a broad irregular belt across the middle of the State, in a northeast-southwest direction. Near the central portion of the State, it occurs as a narrow belt of limestone broadening both to the southwest and northeast where it covers extensive areas.

“The typical Burlington formation usually consists of heavy beds of brown and gray to white, coarsely crystalline limestone. Abundant remains of mollusca and crinoidea occur in this formation, some portions of which are made up chiefly of the remains of crinoidea. From an economic standpoint, it is the most important limestone formation in the State, being extensively quarried at Carthage, Hannibal, Springfield, Phenix, Ash Grove, Peirce City, Walnut Grove, Osceola and other places. At Springfield, Ash Grove and Pierce City it is used chiefly for the manufacture of quicklime and at Hannibal, Phenix and Carthage it is quarried extensively for building stone.

“At Carthage this stone as it occurs in the quarry has a slightly bluish gray tint, the upper beds being whiter than those deep in the quarry. When cut and dressed, the stone is white. Nowhere is the color of the stone more uniform in the different quarries than in the Carthage area. The bluist tint observed in any of the stone was in blocks which had been quarried from the two lower channel cuts of the west opening of the Carthage Marble and White Lime Co. Even this stone, when rock-faced or sawed, has just enough of a blue tint to take away the monotony of a dead white. The faint blue tint gives the stone a life, which a dead white rock does not have. In uniformity of color this is the peer of limestones. In comparison, the Bedford, Indiana, stone is so far inferior as not to warrant consideration.

“The calcite grains are closely interlocked, giving the stone strength and durability. A thin section of this stone, examined under the microscope, shows it to consist mainly of irregular grains of calcite of medium size, cemented together with a calcite matrix. The calcite has a dull grayish color in ordinary light. The faintest possible tinge of iron oxide was observed in two or three parts of the section. However, it is not sufficiently abundant to give color to the stone. No quartz or other minerals of importance were observed. No minerals that might cause discoloration through decomposition were observed. The freedom of the stone from impurities is shown by the following chemical analysis made in the laboratory of this Bureau.

Insoluble - .69

Oxides of Iron and Alumina (Fe2O3, Al2O3) - .21

Carbonate of Lime (CaCO3) - 98.57

Carbonate of Magnesia (MgCO3) - .65

(Total) - 100.12

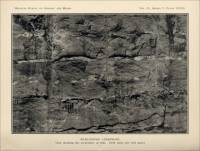

“Stratification planes, having the appearance of the joints in the cranium, which occur in this stone, were called suture joints by the earlier geologists. Later, these became known as stylolites. In this report we have chosen to call them suture joints. In the Carthage limestone, suture joints occur parallel to the bedding and are from two to twenty inches apart. They vary greatly in size, some of them being as much as four inches deep. The smallest of these joints are tight and the stone cannot be split along them as one might suppose. The larger of these joints are frequently open and along them the stone is usually easy to split. These seams injure the appearance of the stone when they occur on a sawed face. To avoid this, the stone is generally sawed parallel to the bedding and laid on edge in the wall. The so-called number one stone, or monumental stock, contains none but the very finest suture joints. An examination of the outcrops show that these joints will open after long exposure to the weather, separating the stone into thin layers.

“In certain parts of the quarries, tar seams or joints occur in the stone. Some of the quarries are almost entirely free from them, while in others, they appear to be restricted to very limited areas. They consist of vertical or slightly inclined joints which contain bituminous material, which appears on the surface of the stone as a black line or dark streak. Stone containing these seams is rejected by contractors and consequently this discoloration may become a source of considerable loss.

“Compared with the Bedford oölitic limestone, the Carthage stone is much more difficult to cut and dress. Two inches per hour is about the average work that can be done in sawing this stone. It has a much lighter and more uniform color than the Bedford stone. It is considerably stronger than the Bedford stone, as is shown by the strength tests given in the table in the appendix.”*

(Please note that the appendix of this book referred to in the above paragraph will not be presented in this document. If you would like a copy of the tests, feel free to contact me. Peggy B. Perazzo)

“The stone polishes nicely and is used quite extensively in monumental work. The difficulty in obtaining large pieces free from suture joints is the greatest drawback to its use for monuments.

“Lenticular and roundish nodules of flint occur in different parts of this formation. They are not scattered promiscuously through the stone, but occur at definite horizons in the formation. These nodules vary in size from several inches to three feet in their greatest diameter. Normal to the bedding planes, they are not usually over ten inches in thickness. As a rule, they do not form a continuous or connected layer. The quantity of flint varies in different quarries. Occasionally a bed contains so much flint as to make the expense of quarrying very great. (See description of the old quarry of the Carthage Marble and White Lime Co.) The floor of most of the quarries is a bed of flint nodules. These beds of flint nodules do not occasion very great waste since the blocks of stone are usually lifted along them.

“The Carthage limestone has no protective layer above it and solution has decomposed the stone along the jointing planes. Due to this process of decomposition, the surface is usually very rough and bouldery. The open seams are filled with clay and are known throughout the district as mud seams.

“Improved machinery is in use in all the quarries. The Sullivan improved Y channeler is being tried in a number of these quarries. This machine will channel up to 150 linear feet per day.”

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Carthage area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Résumé.

“The success attained by the different quarries in the Carthage area has resulted entirely from the excellence of the stone which occurs in that district. Carthage limestone is no longer an experiment. Its strength and durability have been established beyond the question of a doubt. The limestone from Bedford, Indiana, which is its chief competitor, is in no sense as desirable stone as that from the Carthage quarries. This stone has a crushing strength three times that of the Bedford limestone. When dry it weighs 167 pounds per cubic foot, while the Bedford, according to the report of the State Geologist of Indiana for 1896, weighs 154 pounds per cubic foot. A comparison of buildings constructed out of the two stones shows that while the Carthage stone is perfectly uniform in color and shows no discoloration with age, the Bedford limestone is not of uniform color and frequently exhibits a dark efflorescence, both of which are undesirable. The Carthage limestone is essentially free from those mineral constituents which cause discoloration. Very seldom can one detect the presence of sulphide minerals, either fresh or altered.

“The simple mineralogical composition of this stone renders it more capable of withstanding rapid changes in temperature than stone having a complex mineralogical composition. Samples subjected to very rigid freezing and thawing tests in the laboratory showed very little loss in their crushing strength.

“There is an almost unlimited supply of limestone in this area and it is expected that, with proper management, in the next decade the industry will develop into very much larger proportions than at the present time.

| Plate XXVII. Burlington Limestone. View showing the occurrence of flint. Drill holes five feet apart. |  |

“Associated with the lead and zinc mines in the vicinity of Carthage, there are large quantities of chat which constitutes a source of supply of stone for macadam pavements which is unexcelled. This finely crushed flint and limestone is also used in the manufacture of artificial stone and brick, sewer pipe, granolithic sidewalks and curbing, and for many other purposes in combination with cement.

Buildings in which Carthage stone has been used.*

(The headings for the following information are: Buildings - Location - Parts. NOTE: You will see some entries in the list below with “I.T” where the name of the state is usually given.. I believe this refers to” Indian Territory.”)

Sedalia Library Building - Sedalia, Mo. - Base and columns.

Bank of Harrisonville - Harrisonville, Mo. - Front.

State Normal Building - Macomb, Ill. - Steps.

Stillwell Hotel - Pittsburg, Kan. - ---

K. P. & G. Depot - Kansas City Mo. - Piers and trimmings.

W. J. Echols Building - Ft. Smith, Ark. - Piers and Trimmings.

Reynolds Davis & Co. - Ft. Smith, Ark. - Front and trimmings.

Homestead Building - Muscogee, I. T. - Front and trimmings.

Citizens Bank - Muscogee, I. T. - 1st Story and trimmings.

Bank of Muscogee- Muscogee, I. T. - 1st Story and trimmings.

Leaver Building - Muscogee, I. T. - Entrance and trimmings.

Spaulding Mercantile Co. - Muscogee, I. T. - Trimmings

M. E. Church (South) - Muscogee, I. T. - Trimmings.

School Building - Parsons, Kans. - Water table and trimmings.

Deacon, Elder & Deacon Bldg. - Harrisonville, Mo. - Trimmings.

Vinita National Bank - Vinita, I. T. - Front.

Citizens Bank - Checota, I. T. - Front.

Citizens Bank & Development Co. - Wagoner, I. T. - Entrance piers and trimmings.

Citizens National Bank - Chickasha, I. T. - Entrance.

Cotton Belt R. R. Hospital - Texarkana, Ark. - Trimmings.

St. L. & S. W. & St. L. & S. F. Depot - Jonesboro, Ark. - Trimmings.

Frisco Hospital - Springfield, Mo. - Trimmings.

1st National Bank - Clarksville, Tex.

Court House - Ft. Dodge, Iowa - Water table sills.

Four School Bldgs. - Chickasha, I. T. - Trimmings.

1st National Bank - Maryville, Mo. - ---

State Asylum Bldg. - Nevada, Mo. - ---

Luchsinger Block - Appleton City, Mo. - ---

Chas. T. Johnston Residence - Decatur, Ill. - ---

Crawford Co. High School - Cherokee, Kan. - ---

St. Agnes Academy - Ft. Smith, Ark. - ---

Ex-Confederate Monument - Ft. Smith, Ark. - ---

Wm. Patterson Bldg. - Pittsburg, Kans. - ---

Frisco Depot - Jonesboro, Ark. - ---

J. P. Leggett Residence - Carthage, Mo. - Complete.

W. Platt Residence - Carthage, Mo. - Complete.

Jasper County Court House - Carthage, Mo. - Complete.

Wm. Phelps Residence - Carthage, Mo. - ---

Church - Beaumont, Texas - ---

St. Paul’s Sanitarium - Dallas, Texas - ---

Public Library - Kansas City, Mo. - ---

Carnegie Library - Joplin, Mo. - ---

Carnegie Library - Carthage, Mo. - ---

Court House - Jefferson City, Mo. - ---

Bates County Court House - Butler, Mo. - ---

Government Bldg. - Joplin, Mo. - ---

Court House - Paola, Kans. - ---

Court House - Herman, Mo. - ---

“Numerous buildings in St. Louis, Kansas City and Sedalia, Missouri; Wichita, Parsons and Leavenworth, Kansas; Omaha and Lincoln, Nebraska, and Oklahoma City, Okla., have been built out of this stone.”

Clarksville.

“Two quarries, known as the Clifford and the Roberts, are located directly north of Clarksville. The Burlington railroad skirts ...close to the bluff upon which these quarries are located. A large part of the stone taken from them has been used by the government in the construction of retaining walls, break waters, etc., along the Mississippi Rover. It is also used for macadam and foundations. The quarries are worked intermittently.”

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Clarksville area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

| Plate XXIX. Burlington Limestone. Occurrence of fine and coarse Suture Joints (stylolites). Scale 1 in. = 1.25 ft. |  |

Columbia.

“A number of quarries have been opened in the vicinity of Columbia which are operated almost exclusively to supply the local market with building stone. These are all located in Burlington limestone and the stone does not differ essentially in any of the quarries inspected. The main difference is in the thickness of the beds and the quantity of flint in the stone. The quarries now being operated are owned by Nichols Bros., George M. Richardson, J. H. Guitar and L. D. Gordon. Those operated by the first two are located north and northwest and those operated by the last two are south of the city.”

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Columbia area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)

Hannibal.

“All of the stone quarried in the vicinity of Hannibal is limestone of Burlington age. The texture and color of the rock and the thickness of the beds vary locally in the different quarries, but, on the whole, there is a very close resemblance between the stone from all the quarries.

“The most important quarries operated are the following: The Hannibal Lime Company, The Star Lime Company, the Empire Lime Company and the Waller Lime Company. About three miles south of the city the Atlas Cement Company have erected a factory for the manufacture of Portland cement, in the production of which the limestone and shale of the adjacent bluffs are used.”

(Please Note: The section of this book that lists and describes the individual limestone quarries located in the Hannibal area of Missouri will not be included in this section. Please see the Missouri Quarry Section of this web site for the information on each specific quarry, which is listed according to location.)