Excerpts From

Annual Bulletin on Mineral Resources of Kansas, For

1900 and 1901.

Including a Report Upon Gold and Silver, Lead and

Zinc,

Coal, Oil and Gas, Clay Products, Gypsum,

and Hydraulic and Portland Cements,

Building and Other Stone, and Salt.

by Erasmus Haworth

Department of Physical Geology and Mineralogy, University of

Kansas

The University Geological Survey of Kansas

Publication distributed from the University, at Lawrence,

Kansas

May 1902.

Please note: While only a few of the sections of this book will be presented here, you can view all of the photographs in the book by clicking on the word "Illustrations" in the Contents below..

Contents.

Hon. W. C. Spangler, Vice-chancellor of the University of Kansas:

Dear Sir - I have the honor to submit to you herewith my annual report on the mineral resources of Kansas for the years 1900 and 1901, combined in one, which will constitute the fourth annual bulletin of this series. It affords me great pleasure to state that the mining and metallurgical interests of Kansas during the past year were in a prosperous condition, yielding a great increase to the productive wealth of our state.

Yours most respectfully,

Erasmus Haworth.

Department of Physical Geology and Mineralogy,

University Kansas, May 1902.

The mining and metallurgical operations of the state, during the years 1900 and 1901, were conducted along the same lines they previously followed. No strikingly important developments were made at any time during the years; neither were there any remarkable variations in production compared with other years.

An important item of interest is the closing down of the refinery at Argentine, during 1901, indicating that possibly the American Smelting and Refining Company would ultimately abandon the plant. The included tables for 1900 and 1901 fail to show the production of the Argentine plant, the owners positively refusing to give data concerning its output.

The zinc smelting industry practically has been entirely removed to the gas regions, the only coal smelters in operation being run but a short time in 1900, and the Girard smelters being the only ones operated in 1901. It is currently reported that gas smelters can produce spelter cheaper than coal smelters, thus making it impossible to operate the latter. However, it may be noticed that coal smelters at Nevada, Mo., have been in operation almost continuously, as also have those of Illinois. Some light may be thrown on this subject by a careful examination of table VII, which gives the ratio between prices of Zinc in the ore and after it is smelter. It will be noticed by a perusal of this table that the margin for expenses and profits is the smallest for any year yet given. The ratio of price per ton of spelter in the ore and at New York after smelting is 1 : 2.89 for 1900, and 1 : 2.9 for 1901, which is the lowest yet recorded. Also, the actual margin between the selling price of a ton of spelter and the purchasing price of the same in the form of sixty-per-cent. ore is $37.33 for 1900 and $34.92 for 1901, which, again, is the lowest yet known. It is quite evident from these facts that the ore-buyers have paid a higher price for ore relatively to the selling price of spelter than ever before has been done.

The output of coal for 1900 is the greatest, both in tonnage and value, ever yet recorded for the state, the yield being the magnificent sum of more than five and one-half million dollars in value, with the average price per ton at the mine being but $1.25. For 1901 the results are even better. This shows that the coal-mining business is in a prosperous and healthy condition, and that our mines have a capacity sufficient to meet the extraordinary demands placed upon them.

The production of oil for 1900 was not as great as that of previous years, neither was the output of the refinery at Neodesha quite as great as for the year 1899. On the other hand, the production of natural gas was far in advance of previous years. The extraordinary demands for gas in the rapidly increasing manufacturing enterprises now located in the gas-fields is the principal cause of this increase. In addition, gas has been piped into some of the towns which previously were not consumers, and heavy flows of gas have been found in new localities. The difficulty in the way of estimating the actual value of the gas makes different estimates vary greatly. The manufacturing enterprises using gas during the year could not have been kept in operation without a consumption of more than one million dollars' worth of coal. In 1901 the production of oil increased to 169,197 barrels, on account of the large sales from Chanute. The consumption of gas likewise increased their demands greatly, while domestic consumption was the largest ever known.

An industry which has responded promptly and extensively to the new conditions is the manufacture of brick and other clay goods. There has been an unusual demand for all kinds of brick, which has been met quite largely by the brick factories in the gas-fields. In addition to this, the Union Pacific Railway Company has burned a large amount of clay or "gumbo" for ballast, making the value of this one commodity surpass the total value of clay products of the state only a few years ago.

The large Portland cement factory at Iola has done a good business, but has been unable to fill all orders received. As a result, the plant will soon be enlarged to about double its present capacity. It is also reported that another large Portland cement factory will soon be built in the vicinity of Independence.

Other new industries will soon be established in the state. A window-glass factory has already been located at Coffeyville. Two new brick plants are building at Sycamore, a station on the Missouri Pacific Railway, between Neodesha and Independence. Others are springing up in different places, adding greatly to the state's industries.

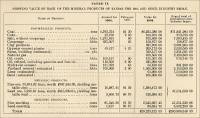

Tables I and II show in a general way the total mineral and metallurgical production for 1900 and 1901.

Table I. Showing Value of Each of the Mineral Products of

Kansas for 1900,

and Since Industry Began.

Table II. Showing Value of Each of The Mineral Products of

Kansas for 1901,

and Since Industry Began.

VIII. Building and Other Stone.

The past biennium has been a prosperous period for the stone industry, which is largely due to the great improvement of road-beds made by the different railroad companies. New culverts have been put in, which have required a large amount of dimension stone, and an unusually large quantity of broken rock has been used for ballast. Rough stone for riprapping has also been in great demand. The various towns and cities of eastern Kansas have used large quantities of flagging stone for building walks, and, likewise, an unusually large amount of stone for curbing, where streets have been paved with brick. The general prosperity of the country has also resulted in more large buildings being constructed than usual, which has consumed the best quality of dimension stone, and thousands of small buildings have used ordinary stone for foundations.

Plate VIII. Rock Quarry, Iola Portland Cement Plant.

In the central part of the state stone fence-posts are used to a great extent. Never before in our history have so many fences been built using stone fence-posts. A strip of country about twenty miles wide, reaching from the north side of the state to the Arkansas river, passing through Osborne, Russell and Rush counties, is the great fence-post area. A limestone belonging to the Benton formation of the Cretaceous is the stone used. It is easily split into long prismatic posts, and is soft enough so that notches are cut at the edges or holes drilled through the posts. The posts are quarried and hauled to the fence lines, sometimes being transported from twelve to fifteen miles. They are set in the ground the same as wooden fence-posts, but usually about thirty to thirty-five feet apart, making from 160 to 175 per mile. Their market value is about twenty-five cents each, delivered at the fence line, and when once in place make a permanent post, which will probably last for hundreds of years. It is difficult, in fact impossible, to gather accurate statistics regarding the value of such posts for the past two years. Anyone familiar with the country, however, can see such a great change in the amount of fencing used, that he would readily admit many thousands dollars' worth of stone have been used in this way each year.

Almost all of the stone used in Kansas is limestone. The famous Cottonwood limestone still ranks far ahead of any in production. A line of quarries reaching two-thirds of the way across the state, from the north side southward to beyond the Cottonwood river, represents exposures of this limestone. Quite likely more than half of the total production of the dimension stone of the state comes from this limestone. The largest individual item in value specified by use is broken stone used for ballast. This, of course, may be obtained from any limestone ledge conveniently located. But first-class dimension stone outside of the Cottonwood stone horizon is not extensively produced, excepting from the softer, less desirable, Permian limestone.

Table XVIII exhibits the total stone production of the state from 1880 to 1901, inclusive.

Table XVIII. Showing Value of Building Stone Produced in

Kansas from 1888 to 1901.

Figures for 1880 to 1896, inclusive, are taken from

the reports of the United States Geological Survey.

Commercial use of material within this site is strictly prohibited. It is not to be captured, reworked, and placed inside another web site ©. All rights reserved. Peggy B. and George (Pat) Perazzo.