Agents of Decomposition.

“In buildings, the decomposition of stone proceeds much more slowly than disintegration. The work of breaking down the chemical compounds is a much greater task than simply overcoming adhesion and cohesion.

“Water. - Water is the most active agent in producing chemical changes in rock. It generally contains, besides mineral salts, either sulphuric, sulphurous, carbonic or organic acids, in solution. Thereby the water is often a very dilute acid solution. As it percolates through the rock, small quantities of mineral matter are taken into solution in one place, and precipitated or deposited in another. In this way, the minerals, of which both the igneous and sedimentary rocks are composed, are broken down and large quantities of the mineral substances are transferred from one place to another.

“The chemical decomposition of minerals in building stone is so slow that it seldom affects the life of the stone after it is placed in a building. Limestone, dolomite, marble and other rocks, in which iron sulphide or iron carbonate occur, are the only building stones which show any appreciable deterioration through the decomposition of their mineral constituents.

“Sulphurous Acid. - The most conspicuous case of mineral decomposition is that of iron sulphide, which breaks down in the presence of water, forming iron oxide and sulphurous and sulphuric acids. In the case of dolomite, these acids act upon the magnesium carbonate producing magnesium sulphate, which is frequently brought to the surface and exposited as an efflorescence or incrustation.

“In cities, where the consumption of bituminous coal is large, sulphurous and sulphuric acids are usually present in the atmosphere in considerable quantities. The effect of these acids increases where the atmosphere is moist. In London where the consumption of soft coal is very large and fogs predominate, there seems to be little question that the effect of these gases is worthy of careful consideration. In the United States, with the exception of a few large cities, these agents have comparatively little influence.

“Carbon Dioxide. - Water which holds in solution or is charged with carbonic acid gas, when passed through calcareous rocks takes into solution more or less of the calcium carbonate. This naturally lessens the adhesion between the different particles and weakens the rock. In nature decomposition from this cause takes place on a very large scale, but in the walls of a building its effect is scarcely appreciable.

“Organic Acids. - the organic acids resulting from decaying organisms have little or no affect upon the strength and durability of stone used in the walls of buildings.”

Chapter III.

The Properties of Stone Used in Building Constructions and Methods of Determining the Same.

“The suitability of a stone for any of the numerous uses to which it may be put, depends mainly upon its color, strength and durability and the condition of the quarry in which it occurs.

“The color of a stone depends upon its mineralogical composition; the strength depends chiefly upon the mineralogical composition and texture; and the durability upon the capacity which the stone has to withstand temperature changes and the action of gases and dilute acids. In order to estimate the quality of a stone based upon its strength and durability one usually determines, -

I. Composition - Mineralogical (&) Chemical.

II. Strength - Crushing (&) Traverse (&) Tensile.

III. Hardness

IV. Elasticity.

V. Porosity.

VI. Presence of fissile planes.

VII. Specific gravity.

VIII. Weight per cubic foot.

IX. Capacity to withstand temperature changes.

(a) Freezing and thawing of included water.

(b) Alternate heating and cooling.

X. Capacity to withstand gases and dilute acids (Carbonic, Sulphurous, etc.)

“One may obtain these facts by three different methods: (1) by making an examination of the stone in the quarry and adjacent natural exposures; (2) by a careful inspection of buildings and other structures built out of the stone under examination; and (3) by a series of laboratory tests. Which of these methods of determining the durability of stone is considered most satisfactory, depends upon the individual making the examination. A geologist would probably select a combination of the first and third methods; an engineer would probably select the third; while a layman or an architect would undoubtedly be best satisfied with the second. The value of an opinion based solely upon quarry observations or building inspection, must depend largely upon judgment and experience. They lack the definiteness and certainty which results from a carefully performed series of laboratory tests. However, no one of these should be considered sufficient in itself, but each should be used to supplement the other two.”

PEGGY - START PROOFREADING HERE pp 31

Quarry Observations.

“In the selection of stone for large buildings, much depends upon the location, condition and equipment of the quarry. These cannot be ascertained by an examination of the building or selected samples in the laboratory, but must be learned from an examination of the quarry. The permanence and uniformity of the color of the stone may also be determined by an examination of the quarry and adjacent exposures.

“The mineralogical composition may be determined approximately, while the hardness, strength, weight and porosity may be roughly estimated at the quarry. The manner in which the stone weathers, as shown by the adjacent outcrops, furnishes a basis for a rough estimate of the durability of the stone.

“A quarry should be located favorably for transportation. If one is required to haul stone by team for any distance, there is always danger of delay on account of bad roads. A quarry is not suitable equipped for filling large orders for building stone until railroad facilities have been provided at the quarry.

“The stone in all parts of the quarry may not be of the same quality. This is frequently the condition in the sedimentary rocks. The stone from one part or from one ledge may be strong and durable, while that in another part, or at another horizon may be unfit for use. It frequently happens that the best stone is deeply buried beneath other beds of inferior quality. The desirable stone is thus made inaccessible, and occasionally the quarryman supplies an inferior stone in place of the better quality. The condition whereby this might happen can only be determined by an examination of the quarry.

“It occasionally happens that the desirable stone in a quarry becomes exhausted, although the owners still continue to sell stone on the basis of the earlier conditions in the quarry. Improper methods of quarrying and dressing and careless handling are frequently such as to warrant one in condemning a stone which otherwise might be desirable. A quarry may be poorly equipped with machinery, men may be scarce, orders for stone may be plentiful and, as a consequence, an inferior product may be marketed. These conditions can best be determined by an examination of the quarry and its equipment.

“The uniformity and permanence of the color of stone can be most satisfactorily determined at the quarry. If the color fades rapidly upon exposure to the atmosphere, it will be shown in the weathered outcrops, which can usually be found adjacent to the quarry. If the stone differs in color at different horizons or in different parts of the quarry, a careful inspection will reveal this condition and precautions may be taken to insure the receipt of stone of uniform color, by designating the ledge and even the portion of the quarry from which the stone is to be taken. The weathered outcrops may show the stone to be bleached, stained with brown iron oxide or discolored with white efflorescent patches. The bleaching process ordinarily takes place very slowly and the depth to which it extends indicates, in a measure, the permanence of the coloring matter. Brown staining usually indicates the presence of iron, and white efflorescent patches give evidence of soluble magnesium or calcium salts.

“Differences which may exist in the mineralogical composition of a stone can often be determined by an examination of the quarry. One who is familiar with the common rock forming minerals may easily detect differences in the composition and texture of the rock by examining it as it occurs in the quarry.

“The strength, hardness, elasticity and porosity of a stone depend upon its mineralogical composition and texture. therefore, if one is acquainted with the mineralogical composition, as well as the size, shape and manner of contact of the individual grains, he may estimate approximately these qualities, which otherwise must be determined by physical tests in the laboratory. The experienced observer should not only be able to detect differences I the qualities of stone from different parts of the same quarry, but he should also be able to make comparisons of stone from different quarries and districts.

“The durability of a stone may be estimated simply by comparing the weathered and fresh exposures in the quarry. Such estimates must be very rough, owing to the uncertain length of time during which the weathered surface has been exposed to the atmosphere. The stone may have been uncovered for centuries, or perhaps only a few years.

“In glaciated regions, the hardness may frequently be estimated from the depth and extent to which the surface has been grooved and striated. Owing to the fact that these markings are controlled in part b the condition of the glaciers, they are sometimes very uncertain evidence from which to estimate the hardness of a rock. The length of time that the surface has been exposed to the atmosphere since glaciation also affects the condition of the striae, making them a less important criterion of hardness.

“Where disintegration and decomposition have not extended to too great a depth, the natural exposures will reveal inequalities in hardness resulting from concretions, nodules, pebbles, clay seams or pockets and fossils.

“Structures, such as sedimentary ad jointing planes, which may be obscured in the freshly quarried rock, are emphasized by weathering. Quarrymen often contend that joints die out with depth, but this cannot be laid down as a general rule within the superficial zone to which quarrying may profitable extend. Some joints which show at the surface are undoubtedly superficial, but others penetrate to very considerable depths. It is thought that the depth to which joints extend is in a measure proportional to their length.

“The durability of a stone may be estimated from the depth to which disintegration and decomposition have extended. The time element, however, enters again to vitiate more or less the conclusions. A luxurious growth of lichens on the exposed surface of the rock is frequently considered an evidence of durability. However, this criterion when taken alone, has very little significance. Lichens frequently grown in abundance on the surface of sandstone which is inherently soft. In this case, however, the indicate that a crust has been formed on the surface of the stone.

“It is very necessary that one should visit a quarry to assure himself that the amount of stone of the desired quality is obtainable. It frequently happens that a quarry becomes exhausted of its good stone and for this reason one should acquaint himself with the conditions at the quarry. On the other hand, quarries which have a high percentage of excellent stone, have frequently been condemned by the public because the quarryman or contractor has permitted the use of a few inferior blocks in conspicuous places. If one wishes to know positive that he is receiving the best stone that a quarry produces, he should be personally acquainted with the possibilities of the quarry.”

Observations on Buildings and Other Constructions.

“The inspection of buildings long standing has always been recognized as an important means of estimating the strength and durability of stone. The value of such observations, however, is often over estimated because frequently one cannot know how the stone was quarried, handled, dressed or laid.

“Any estimate of the strength and durability of a stone made from the examination of a building should take into consideration (1) the age of the building, (2) its size, (3) the climatic or atmospheric conditions, (4) its situation, (5) the grade of stone used and the manner in which the stone was quarried, handled, dressed and laid.

“It is worse than folly to estimate the strength and durability of the stone in a building without knowing the age of the building. During the first twenty-five years, a stone may not exhibit any material deterioration, while the next ten or fifteen years may show rapid decay. Very few of the buildings in the United States can be considered old, and the actual disintegration is comparatively little. Many that are fifty or more years old, do not exhibit the first signs of decay. Frequently the actual disintegration is so slight that one must content himself with searching for the beginnings of decay. It is interesting, however, to note that in some instances disintegration has proceeded so rapidly as to render the buildings at the present time unsafe.

“The rate of decay may be increased by the height of a building. Apparently the weight of the superstructure assists the atmospheric agents in their work of destruction.

“The location of a building, in the business or residence part of a city, protected or exposed to the storm and prevailing winds, will influence more or less the life of a stone. Likewise, the location of a building, in an atmosphere which is temperate, torrid, frigid, humid or arid, will affect its permanence. A stone which might remain unchanged for centuries in an arid region will frequently crumble and decay, in a few years, in a moist temperate climate.

“The grade of stone affects very materially the life of a building. It is not uncommon for the poorer grades f stone to be used in the fronts of buildings or even carved for the finer parts of architectural work. after a stone once becomes a part of a building, people do not stop to distinguish different grades, but attribute the weaknesses or imperfections in the inferior grade of stone to the quarry as a whole. It is not unusual for the stone from an entire district, including several quarries, to be condemned because second or third grade stone has not proven as satisfactory as number one stone from another district.

“The manner in which the stone is quarried, handled, dressed and laid is also very important. Much stone is still being laid on edge, especially in veneer work. In case the bedding planes are prominent and the stone is only of moderate strength, this practice is dangerous. A stone which is strong and durable, when laid on the bed, may be weak and imperfect when laid on edge. One should ascertain if possible whether the flaking and scaling is due to inherent weakness in the stone or to improper methods of laying.

“Stone used for ornamental and monumental purposes will show deterioration in proportion to its age, position, etc., the same as stone used in the walls of buildings. The same care should be exercised in passing judgment on its durability as if it were a part of a building.

“The oldest monuments in our cemeteries are marble, it being only within a few years that granite has come into very general use. Some of the granite monuments, in spite of the comparatively recent date of their erection, are gradually losing their polish, and even now have very finely pitted surfaces. The lettering is frequently dimmed and the polishing obliterated on monuments that have been exposed a very few years to dust laden winds. The diurnal expansion and contraction, caused by heating and cooling, often result in deterioration on the surfaces exposed to the direct rays of the sun.

“The perfection of the polish which a stone will take and the contrast between the hammered and polished surfaces can be best ascertained from the finished work. However, one should not permit the elaborateness or excellence of workmanship to influence the judgment. The polished surfaces are sometimes oiled, giving a brilliancy and luster which is not inherent in the stone itself. For this reason, a monument should not be fully accepted until it has been exposed to the atmosphere for at least six months.

“The strength and durability of stone used for highways can be in a measure estimated by inspecting pavements and sidewalks, which have been constructed out of the materials in question. a just comparison, however, can only be made, when the manner of construction, the amount of traffic, the character of the subsoil, the climatic conditions and the date of construction are known. One may determine from an examination of pavements the durability of the materials and whether or not they become slippery or uneven by wear. These facts, however, can be obtained more accurately and with less trouble by testing the stone in the laboratory.”

Laboratory Tests.

“A knowledge of the mineralogical and chemical compositions and phrasal properties of a stone, and the climatic and other conditions to which it will be subject when in use, furnish a basis from which one can predict with are remarkable degree of accuracy, without inspecting the quarry or examining buildings of long standing, the results of exposure to the atmosphere. it is not always possible or convenient to have a stone tested in the laboratory and frequently quarrymen do not seek it. Architects and contractors, however, are always glad to have at their command reliable laboratory tests on stone.

“There are three important classes of laboratory tests, namely, (1) chemical, (2) microscopical, and (3) physical.

“Chemical. - The only exact method of determining the elements of which a rock is composed is by means of a chemical analysis. This is also the best method of determining the proportions in which the mineral constituents are present. the presence of deleterious constituents, such as ferrous iron, bitumen, etc., and the quantity of each present may be determined in this way. Ordinarily a chemical analysis is the least important of the laboratory tests, but it can be made useful in estimating the durability of a stone in case a microscopical examination is impractical.

“Microscopical. - Much may be learned of the strength and durability of stone through a microscopical examination of thin sections. By the aid of a magnifying glass, one can determine approximately the mineralogical composition and texture of a coarse grained stone.

“In the case of a very fine grained rock, the mineralogical composition and texture can only be accurately determined by a microscopical examination of thin sections.

“The microscopical examination is not only less expensive, but it is of much greater practical value than a chemical analysis. It is known that the durability of a stone depends upon its mineralogical composition and texture, each of which can be determined with a high degree of accuracy by the use of a microscope. It is possible by aid of the microscope to determine not only the relative abundance of the different minerals, but also the chemical composition. Minerals that are readily decomposed and liable to cause discoloration can be identified, and the presence of cracks, strains and gas bubbles can be detected. It is possible to estimate, with a fair degree of accuracy, the compressive, cross breaking and tensile strength of the stone, from a knowledge of the mineralogical composition and texture combined with a knowledge of the physical properties of the different minerals of which the stone is composed. for this purpose one should have a knowledge of the compressive and cross breaking strength of the different minerals, a well as a knowledge of the proportion in which each of these minerals is present in the rock, the size of the grains, and the manner of contact.

“Frequently cracks and strains observed in thin sections are due to stresses, resulting from cutting and grinding. For this reason one should be careful in drawing conclusions from their presence in the sections examined.

“The size and abundance of the pore spaces can be estimated from the texture, closeness and manner of contact of the grains. It is though that one might possibly measure these spaces quantitatively under the microscope by saturating the rock with a colored gelatinous substance which sill fill the pores.

“All of the characteristics of a rock which contribute to their strength, hardness, elasticity, capacity to withstand alternate heat and cold and freezing and thawing, and the effects of carbonated and acidulated waters, can be approximately determined by an examination of thin sections under the microscope. It is thought that an intelligent interpretation of the facts revealed by the microscope might eventually render the physical tests and chemical analysis unnecessary. At present, however, the microscopic examination of thin sections is only intelligent to the petrographer. he is the only one who can interpret the facts thus observed and the accuracy of his conclusions will depend upon his judgment and experience. With the public, this method may never supplant the physical tests, because it lacks the quantitative element.

“Physical Tests. - The purpose of the physical tests is to determine by artificial methods the strength and durability of a stone. On account of careless methods of quarrying, handling, dressing and laying, the decay of stone in buildings is not always evidence of inherent weakness. For this reason the physical tests, obtained in the laboratory, provide a more reliable basis from which to estimate strength and durability.

“The strength and elasticity of a stone can both be obtained very easily by preparing cubical and rectangular pieces to be used in testing machines constructed for making these determinations. It is more difficult, however, to express quantitatively the deterioration through atmospheric changes, on account of the practical impossibility of measuring in a few weeks or months, in the laboratory, any deterioration that might take place in years under ordinary climatic conditions. Besides this, the conditions in nature change daily both in intensity and kind and, as a rule, there are several agents of destruction, instead of one, operating at any given time. The effect of these agents in the laboratory must be measured separately and on such a grossly exaggerated scale that there will be accomplished in a brief period that which would require many years in nature.

“The following determinations at usually made as a basis for estimates of durability:

I. Strength.

(a) Compressive, or crushing.

(b) Transverse.

(c) Tensile.

II. Elasticity, modulus.

III. Hardness - coefficient of wear.

IV. Specific gravity.

V. Porosity.

VI. Weight per cubic foot.

VII. Capacity to withstand temperature changes.

(a) Freezing of included water.

(b) Effect of extreme heat.

VIII. Capacity to withstand gases and dilute acids.

(a) Carbonic acid.

(b) Sulphurous acid.

“In a former report, an attempt was made to classify the tests under ‘strength tests’ and ‘durability tests.’ Such a classification is thought to be illogical, because some of the tests have a double significance, indicating both strength and durability.”

Strength.

“Heretofore it has been customary to determine chiefly the compressive strength of building stones. It is thought to be important, however, that one should be familiar with the compressive, tensile and cross breaking strength, as shown by the crushing, cross breaking and tensile strength tests.

“Crushing Strength. - Up to within a few years the durability of a stone has been estimated mainly from the crushing or ultimate strength as determined by the compressive strength test. However, a stone having a low crushing strength may be more durable than one in which the crushing strength is high. For this reason this test is not sufficient for estimating the durability of a stone. The absence of other tests has probably been the cause for frequently overestimating the importance of the crushing strength. On the other hand, it is argued by some that the determination of the crushing strength, except in doubtful cases, is entirely unnecessary. Although this may be in a measure true, I do not consider it wise to encourage the abandonment of the crushing strength test. Architects are very glad to avail themselves of all information giving the crushing strength of stone which they have under consideration for use in buildings. the only intelligible method of expressing the strength of a stone, to one not familiar with the interpretation of the mineralogical composition and texture, is in pounds per square inch.

“The crushing strength is useful in estimating the durability of a stone, as well as having an important scientific bearing upon problems in dynamic geology.

“In very large buildings, single columns or blocks are often required to carry very heavy loads. They frequently support bridge trusses and other constructions of equal weight. It is important to know, approximately, the crushing strength of a stone which is to be used for these purposes.

“In ordinary buildings, the lower courses of stone are not required to carry a very heavy weight of superstructure. It has been computed that the stone at the base of Washington’s monument sustains a maximum pressure of 22.658 tons per square foot, or 314.6 pounds per square inch. A stone is usually required to withstand twenty times the pressure to which it will be subject when placed in a wall. This factor of safety, however, would require for stone at the base of this monument, a crushing strength of only 6,292 pounds per square inch. The pressure at the base of the tallest buildings in this country can scarcely exceed one half of that at the base of this monument, or 157.3 pounds per square inch. In such positions, with a factor of safety of twenty, the stone would not be required to have a crushing strength of more than 3,146 pounds per square inch. There are very few building stones in the country that do not have a crushing strength higher than this. It may happen, however, that as the result of an unequal distribution of the load, certain stones in the wall or columns will be called upon to sustain twenty or even fifty times their proportion of the load, in which case the crushing strength should be much greater. In general, however, a crushing strength of 5,000 pounds per square inch is considered sufficient for all ordinary building constructions.

“The crushing strength of a stone is obtained by breaking 2-inch cubes in a testing machine constructed for this purpose. These cubs can be prepared in any laboratory, which is provided with appliances for cutting and dressing stone. The cubes should be of uniform size and very carefully sawed from a stone block which has not been injured by rough handling or hammer dressing. The faces should be rubbed smooth and the opposite sites should be perfectly parallel. Smaller or larger cubes may be used, although some authors still maintain that the crushing strength per unit of area varies with the size of the cube tested. General Gilmore at one time constructed an empirical formula for reducing all tests to pounds per square inch on 2-inch cubes. It has been shown, however, that this formula is neither theoretically nor practically true. It is the almost general belief now that the crushing strength per square inch does not vary with the size of the cubes nor with their cubical or prismatic shape. this question, however, is not settled to the satisfaction of all, and until it is, it is thought best that all tests be made on 2-inch cubes.

“Before making the tests the stone should be thoroughly dried and the average area of the bearing faces determined. To assist in distributing the load and to take up any unevenness in the bear faces, thin strips of blotting paper, wood, lead or plaster of paris are often placed between the steel plates of the machine and the bearing faces of the stone cubes. It is claimed by some, however, that this has a tendency to lower the crushing strength of the stone. If the cubes have been carefully prepared, this will be unnecessary, and the author believes that, for the sake of uniformity, it would be best to apply the bearing faces directly to the steel plates of the machine, a spherical compression block being used in making the test. A record should be kept of the direction in which the pressure is applied with respect to bedding. The crushing strength per square inch is computed by dividing the ultimate strength of the block by the average area of the bearing surfaces in square inches. One should note carefully the load at which the cubes are first cracked, the ultimate strength, the perfection of the resulting pyramids and the explosive manner in which the cubes may break.

“While conducting a series of tests in the preparation of another report on ‘Building Stones’ it was ascertained that stone when subjected to compressive stresses, much below its ultimate strength - either continuously or intermittently - would weaken. In a subsequent chapter will be found a series of tests illustrating this phenomenon which is known as ‘fatigue in stone.’ This is the first attempt which has yet been made to show this property in stone and the importance of the results cannot, at this time, be estimated.

“Transverse Strength. - The force required to break a bar of any material one inch square when resting on supports one inch apart, the load being applied in the middle, is known as the transverse strength, which is measured in terms of the modulus of rupture. The importance of this determination has not been fully recognized, if one should judge from the data available. The need of a more general appreciation of the value of this test is apparent to any one who has observed the broken caps and sills in many of the larger buildings in this country. frequently one finds a stone that has a low modulus of rupture as to be unfit for use in a position where only a moderate transverse strength is required.

“The thickness of a sill or cap depends mainly upon the transverse strength of the stone. the danger from weak stone and unequal stresses is often so great that doors and windows are arched instead of being capped with a single stone.

“The pieces used for determining the modulus of rupture should be prepared by sawing and should have a cross section of one square inch and a length of from 6 to 8 inches. The sides should be smooth and the opposite ones parallel. The pieces thus prepared should be placed in a testing machine in which both sides are supported on knife edges and the pressure applied to the middle. The weight required to break the sample and the place where the rupture occurs should be carefully noted. The modulus of rupture may be computed from the following formula:

W = 2bd/ (over) 3L - R from which

R = 3L (over) 2bd2 - W.

W = concentrated load at center in pounds. B = breadth in inches. D = depth in inches. L = length. R = modulus of rupture in pounds per square inch.

“Tensile Strength. - Up to the present time apparently no one has endeavored to determine directly the tensile strength of stone of any kind. This can be obtained by preparing pieces similar to those used for determining the tensile strength of cement. They are made carefully by sawing and rubbing, in order to avoid any possible injury that might be occasioned by using a hammer and chisel. The briquettes are made so that the weakest section is at the center and this has a 1-inch cross section.

“Before testing, the briquettes are carefully dried and the bearing surfaces are made parallel, so that the line of contact with the clips are nearly perfect. The briquettes are properly centered in the clips so that the test piece adjusts itself to an even bearing.

“Tensile strength tests of this character may be made in the Michaelis, Fairbanks, Riehle or Olson testing machines. The tests referred to in this report were made in an Olson machine.

“Modulus of Elasticity. - The modulus of elasticity is synonymous with coefficient of elasticity, and is sometimes defined as the weight that would be required to stretch a rod one square inch in cross section to double its length. The result is usually expressed in pounds per square inch. It is ‘valuable in determining the effect of combining masonry and metal; of joining different kinds of masonry or of joining new masonry to old; in calculating the effect of loading a masonry arch; in proportioning abutments and piers of railroad bridges subject to shock, etc.’ (Baker). One method of measuring the modulus of elasticity is by recording the amount of compression which a 2-inch cube of stone undergoes for each increment of 500 to 1,000 pounds load to the limit of elasticity. from the data thus obtained, the modulus of elasticity may be computed by the use of an empirical formula. The value of this determination from a commercial standpoint is somewhat doubtful, owing to the fact that it is seldom referred to by architects. One reason for their not being used is probably due to the comparatively few tests which have been made.

“Hardness. - Wherever in masonry construction a stone is subjected to abrasion, it is desirable to know its hardness. This can be determined quantitatively by the use of the abrading machine. the results of this test are expressed as the coefficient of wear. The Duval abrading machine is the one most commonly used to determine the wearing qualities of stone to be used in macadam pavements. This ‘consists of four cylinders, each twenty centimeters in diameter and thirty-four centimeters in depth. Each of these cylinders is closed at one end and has a tightly fitting cover for the other. They are fastened to a shaft so that the axis of each cylinder is at an angle of 30° with the axis of rotation of the shaft. the shaft which holds the cylinder is supported by bearings, and at one of its ends is a pulley by which the cylinders are revolved, at the other a revolution counter.’*

(* Page 42 footnote: Sixth Annual report of the Massachusetts Highway Commission, page 59.)

“In performing this test no stone whose greatest dimensions is more than 2 ½ inches or less than 2 inches is used. Five kilograms of the stone are used in making the test. After the sample is weighed it is place din a cylinder and the cover bolted on. When a sample has been placed in each of the cylinders, they are revolved at the rate of about 2,000 revolutions per hour until they have Benn given 10,000 revolutions.

“The contents of each cylinder is removed and that which will pass through a 16 mesh sieve is weighed. the loss of weight of the stone, as measured by the dust passing through a 1-16 in. mesh sieve, is the measure of the wear of the stone. The co-efficient of wear, as adopted by the National school of Roads and Bridges of France, is expressed by the formula, Co-efficient of wear = 20 X 20 (over) w = 400 (over)w, where ‘W’ is the weight of the dust which passes through a 1-16 inch mesh sieve in grams per kilogram of stone used.

“It is thought that this test is valuable not only for determining the wearing qualities of crushed stone for macadam, but also for determining the suitability of stone for steps, sidewalks and flooring.

“Specific Gravity. - The specific gravity determinations of building stones, which have thus far been made, are based upon two different conceptions. In the first case the specific gravity has been based entirely upon the mineralogical composition, being independent of the porosity of the stone. According to the second conception, the pores have been considered a part of the stone and the specific gravity computed for the exterior volume. The result according to the first conception has been designated by Regis Chauvenet as the ‘specific gravity proper;’ that according to the second conception as the ‘apparent specific gravity.’ In case the porosity of the stone is less than one percent, the specific gravity determined by either method is nearly the same, but where the porosity is more than 10 per cent. the results are very different.

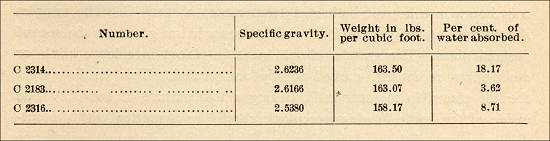

“The principal laid down by Prof. J. C. Smock,* that the specific gravity of the particles, or mineral species, composing the rock mass determines that of the stone, has been followed by most writers. The engineer, however, objects to this method because the weight of the stone per cubic foot in this case cannot be obtained directly by multiplying the specific gravity by 62.5 which is the weight of an equal volume of water. Unfortunately several contemporary writers on building stones have made the mistake of computing the weight per cubic foot by multiplying the ‘specific gravity proper’ directly by 62.5. The following table shows the results of experiments on three different stones as published by one author:**

(* Page 43, footnote 1: Bulletin of the N. Y. Museum, Vol. II, No. 10, page 374, Prof. J. C. Smock.)

(** Page 43, footnote 2: Bulletin of N. Y. State Museum, Vol. II, No. 10, table page 358 by Francis A. Wilber.)

“This table gives the weight per cubic foot of a stone which absorbed 18.17 per cent. of water as greater than that of the stone which absorbed only 3.62 per cent., although the difference in specific gravity is only .007.

“Another writer says: ‘If we find that a stone has a specific gravity of 2.65...we get its weight by simply multiplying 62.5 by 2.65 which gives us 165.62...’*** In this statement the specific gravity refers to ‘specific gravity proper’ and not to eh ‘apparent specific gravity.’ The weight per cubic foot obtained in this manner is obviously incorrect. Similar inaccuracies in the determination of the specific gravity and weight per cubic foot occur in other published reports, but those quoted above suffice as illustrations.

(*** Page 43, footnote 3: The building and decorative stone of Maryland, Maryland Geol. Surv. Vol. II, page 119, geo. P. Merrill)

“In accordance with the principle laid down by Prof. J. C. Smock, it is thought that the specific gravity should be that of the particles or mineral species composing the rock mass and that the apparent specific gravity should not be used except in computing the weight of the stone per cubic foot. There is no inconsistency in this, in so much as the commercial weight considers only the external volume and does not consider the stone as a geometric solid. If there be no other satisfactory reason, for the sake of uniformity there should be a recognized method of computing the specific gravity of stone.

“The ‘specific gravity proper’ of a rock may be obtained by weighing the sample in air at a definite temperature, after all interstitial water has been expelled from the pores; then weighing it completely saturated with water, in water; and finally dividing the weight in air by the difference. Absolute freedom from interstitial water in one case and complete saturation in the other are difficult to obtain. Nevertheless, if accurate methods are employed and care is exercised in performing the experiments, it is thought that a high degree of accuracy can be obtained.

“For the sake of uniformity, all tests should be made on two-inch cubes similar to those used in determining the crushing strength. The samples should be cleaned by carefully washing, and dried for twenty-four hours in a hot air bath at a temperature of 110° C. The samples should ten be weighed and the weights recorded in grams to the second decimal place. The samples should next be placed in a large bottle of or other glass receptacle, corked tightly and sealed. This bottle should then be placed in a water bath, having a temperature of 100° C. The inside of the bottle or glass receptacle should be connected with the outside by means of three glass tubes, one leading to an air pump, another to a manometer and the third to a basin of boiling water. By means of the air pump, the air in the bottle should be exhausted until pressure registered by the manometer attachment is lowered to at least one-fourth of an atmosphere. The pressure should be maintained at this point, while distilled water of 100° C. is drawn into the bottle through the third tube. This tube which conveys the water should be partly rubber, regulated by a stop-cock, and should extend to the bottom of the glass receptacle containing the samples. By operating the stop-cock while the air pump is running, it is possible to keep the pressure nearly constant and at the same time draw any desired amount of water into the bottle. The water which slowly fills the vessel from below gradually replaces the air in the pores as it works its way upward into the stone. The cubes should be completely covered with water and allowed to remain in the bottle twenty-four hours with the pressure maintained at one-fourth of an atmosphere. The cubes should be quickly transferred from the bottle to a basin of distilled water and removed to the weighing room. Before weighing, the water adhering to the surface should be deftly removed by the use of blotting paper. After removing the water adhering to the surface, the samples should be weighed quickly in order to prevent loss through evaporation. The samples should not be laid upon the table or elsewhere during their transfer from the water to the scale pan. errors in determining the weight may creep in through the use of blotting paper or as a result of evaporation. Owing to this, the accuracy of the determinations will depend very largely upon the skill and judgment of the operator.

“After these weights are recorded, the samples should be suspended by a silk thread in distilled water and again weighed. The samples should then be transferred to a hot air bath and dried at a temperature of 100° C. or until the interstitial water has been entirely expelled. The samples are weighed again the weights recorded. From the weights thus obtained a specific gravity is determined by dividing the average of the two dry weights by the difference between the average dry weight and the weight of the cub suspended in water.

“The apparent specific gravity can be readily obtained by subtracting the weight of the sample suspended in water from the weight of the sample saturated with water and dividing the average dry weight by this difference.

“Porosity and Ratio of Absorption. - Both of these terms have been used to apply to the percentage of the weight of the absorbed water to the average weight of the dry sample. This, however, does not give the actual percentage of pore space, but is simply the relation between the weight of the rock and the weight of the water absorbed. The term porosity applies to the actual percentage of pore space in the rock, while the ratio of absorption refers to the percentage of the weight of the absorbed water to the average weight of the dry sample. The former gives the volume relation and the latter the weight relation. As far as known, the actual pore space or porosity of building stones in this country was never determined prior to the publication of the report upon the ‘Building and Ornamental Stones of Wisconsin’ in 1898. It is thought, however, that the determination of the porosity is more important than that of the ratio of absorption.

“The usual method of obtaining the porosity is about as follows: The sample to be tested is heated at a temperature of 100° C. to drive off the moisture. After cooling, the sample is weighed and then slowly immersed in distilled water. After bubbles cease to be given off, the sample is removed from the water and the surface quickly dried with bibulous paper, after which the specimen is again weighed. The difference in weight gives the increase due to absorption. This difference divided by the weight of the dry stone is the ratio of absorption or porosity.

“There are several errors in this method of determining porosity. The interstitial water is not easily expelled at a temperature of 100° C. If one wishes to expel the moisture from a stone within a moderate length of time, the stone must be dried at 110° C. besides this, the sample cannot be completely saturated ‘by immersing in distilled water until bubbles cease to be given off.’ Finally the method of computation gives the ratio o absorption and not the actual percentage of pore space or porosity.

“The porosity of a stone is best obtained in the following manner, using the determinations made in performing the tests for specific gravity. Subtract the average weight of the dry sample from the weight of the saturated sample. Multiply this by the specific gravity of the stone. This gives the weight of a quantity of stone equal in volume to the pore space and of the same specific gravity as the stone tested. The porosity or percentage of pore space will be this weight divided by the weight of the dry stone.

“The ratio of absorption is easily obtained by dividing the weight of the absorbed water by the weight of the dry stone. In another part of this paper, it has been pointed out that the durability of a building stone is not indicated by its porosity or ratio of absorption. It was shown that the size of the pores is by far the more important consideration. When the size and shape of the grains and the percentage of pore space are known, one can estimate roughly the size of the pores. However, if only the ratio of absorption is available, the calculation of the size of the pores is liable to be less accurate. The porosity and not the ratio of absorption is the test which is desired. The porosity is usually higher than that of the ratio of absorption and may therefore meet with disfavor among quarrymen. When it is known, however, that the value of a stone cannot be estimated form its porosity, except when the size of the pore spaces is known, objections will cease to be made. The porosity should always be determined in preference to the ratio of absorption.

“Weight Per Cubic Foot of Stone. - When first quarried, the weight of any stone depends upon its specific gravity, the amount of pore space and the water content. Of these, the only varying element is the water content, which in the more porous rocks, will vary at different seasons of the year, depending upon the thoroughness with which the stone has been seasoned. To determine the weight per cubic foot of stone which contains an indefinite quantity of interstitial water is both unscientific and unsatisfactory. such determinations depend upon a number of conditions, changes in any one of which will give a different result. The only constant weight is that of the dry stone.

“The weight of a stone for commercial purposes may be obtained in two ways, first, by weighing directly a known volume of the stone which has been thoroughly dried at a temperature of 110° C.; and second, by computation from the data obtained in determining the porosity. The eight by the second method is determined by multiplying the weight of a cubic foot of water by the ‘specific gravity proper’ of the stone and subtracting therefrom the weight of a mass of stone of the same specific gravity and equal in volume to the pore space of the given rock.

“A simpler method would be to computer the ‘apparent specific gravity,’ as directed above, and multiply this by 62.5, which should give the same result.

“Effect of Temperature Changes. - The durability of stone depends very largely upon its capacity to withstand changes of temperature. Such changes result in expansion and contraction of the mineral constituents and of the rock as a whole and may also result in the freezing and thawing of interstitial water, on account of which the stone may be weakened.

“Thus far, comparatively few tests have been made to determine the effect on building stone of the alternate freezing and thawing of interstitial water. The importance of such experiments has never been questioned, but the difficulties in manipulation and the many conditions which need consideration before conclusions can be drawn from the quantitative results have had the effect of almost excluding these tests from the tests on building stone.

“The effect of alternate freezing and thawing upon a stone saturated with water may manifest itself in three ways. First, cracks may form; second, small particles or grains may be removed from the surface, causing a loss in weight; third, the strength of the stone may be lessened. The first result is only occasionally observed in testing the samples in the laboratory owing to the careful selection of the pieces used in testing. However, where the bedding planes are prominent, these may open up, splitting the stone into thin layers. The second and third results usually occur and can be measured quantitatively in the laboratory.

“The effect of alternate freezing and thawing of the interstitial water has been determined by two different methods, known as the natural and artificial. By the natural method, the samples are soaked in water and alternately frozen and thawed, a few or many times, at the convenience of the experimenter. By the artificial method, the stone is saturated in a boiling solution of a soluble salt, such as sodium sulphate, and then allowed to dry. As the water evaporates, the salt crystallizes and expands producing stresses similar to those which result when water is frozen. The last method should be employed only when there is no opportunity to freeze the samples under conditions which more nearly accord with those present in nature.

“Two-inch cubes should be used in making the freezing and thawing tests the same as in the previously described experiments. In case the experiments are made during the winter months, when the temperature is below the freezing point, the samples can be saturated with water which has been cooled nearly to the freezing point, and then placed out of doors. If freezing temperatures do not prevail in the climate where the experiments are being performed, access may be had to a cold storage building where the necessary temperature may be obtained. Freezing mixtures may also be used to obtain the desired temperature.

“The samples which are to be tested should first be thoroughly cleaned and dried in a hot air bath at a temperature of 110° C. They should then be carefully weighed and saturated with distilled water, after the manner outlined in the discussion of the specific gravity test. The water used should be cooled almost to the freezing point before the cubes are removed to the place of freezing. They should be allowed to remain in the freezing temperature until thoroughly frozen and then thawed out. While freezing, the cubes should be placed in contact with a moderately porous stone which will serve as a natural drainage for the sample saturated with water. This operation should be repeated thirty or forty times after which the cubes should be dried in a hot air bath at a temperature of 110° C. They should then be weighed. the difference between this and the first weight will be the loss resulting from the test. The samples should be examined to discover any cracks that may have formed as a result of the freezing.

“The frozen cubes should finally be crushed in a testing machine to determine their compressive strength,. the results thus obtained should be compared with the tests made on unfrozen cubes of the same stone to ascertain the loss of strength.

“The loss in weight during a period of thirty-five days is due mainly to the removal from the surface of small particles which are loosened in the process of cutting the sample. In the case of stone which has prominent bedding planes the loss may result from the removal of flaks or thin laminae. Where the stone is a dense fine grained limestone containing small cavities the corners may be broken off. The surface of the sandstone samples which have been sawed or hammer dressed contain many partly loosened grains which fall away from the mass of the stone very readily. The freezing of the water which fills the minute cracks and pores at the surface exerts sufficient pressure to accomplish this.

“The sedimentary rocks, such as sandstone, have more loose grains at the surface than finely crystalline limestone or granite. Except in case a stone is strongly bedded or contains cavities alternate freezing and thawing thirty or forty times will scarcely result in anything more than the removal of the loose particles from the surface. Sandstone in which bedding planes are absent will lose less in weight during a second period of freezing and thawing than during the first.

“Determinations of the result of freezing and thawing on the strength of stone did not receive consideration until the publication of the Wisconsin report on ‘Building and Ornamental Stones.’ As stated in that report, it is thought that the determination of the loss in weight is of comparatively little value in estimating the effect of freezing and thawing on the durability of most stone. The opening up of cracks and the effect on the crushing strength are obviously more important. If a stone is saturated with water and repeatedly frozen while a portion of the pores are filled with water the adhesion of the particles must be weakened, although there may be no loss in weight. It is not reasonable to suppose that the strains produced can be measured by the direct loss in weight through the removal of particles from the surface. he deterioration from this cause can be better measured by determining the loss in strength. Experiments which were performed in the preparation of the report on ‘The Building and Ornamental Stones of Wisconsin,’ lead to the belief that this test is more important than the determination of the loss in weight. It is thought that this test, although not supplanting the other, will eventually take precedence over it in the testing of building stones.

“Extreme Heat. - It is known from observation that rapid and extreme changes in temperature not only weaken a rock, but cause actual disintegration. The capacity to withstand extreme heat is one of the essential qualities of a good building stone. Brick, stone and wooden structures have suffered destruction alike in the great conflagrations in our cities. brick and granite walls have crumbled into shapeless masses, while iron beams and girders have been melted and twisted out of shape.

“Some materials are destroyed at comparatively low temperatures, while others are barely affected at a temperature above the melting point of copper. Very few building materials are unaffected by extreme heat.

“Rocks are poor conductors of the heat and for this reason the surface of a block may be highly heated, while the interior remains comparatively cold. the sudden cooling of a heated block of stone causes the contraction of the outer shell, resulting in differential stresses which may rupture the rock. The water which is thrown into a burning building during a conflagration largely increases the danger of injury to the stone by causing rapid changes in its temperature. During winter the results are intensified by the freezing of the water which collects in the cracks formed by the alternating temperatures.

“Thus far very few experiments have been performed to determine the effect of heat or cold when applied directly to stone. Such experiments as have been performed show that a stone will withstand a much higher temperature when heated and cooled slowly than when heated and cooled rapidly.

“In making temperature tests two-inch cubes are placed in a muffled furnace and gradually heated to a high temperature. By using a standard pyrometer or substances of known fusibility, such as seger cones, the visible effects of the increase in temperature can be noted. Not only should one ascertain the effects of gradually heating and cooling the blocks, but he should also ascertain the effect of sudden cooling by plunging the samples when highly heated into cold water.

“In the case of limestone or dolomite the effect of gradual heating will be manifest by calcination, while sudden cooling will result in flaking off the corners. Sandstone and granite may show very little outward appearance of injury, although their strength may be so affected, especially in the case of sandstone, as to permit of their being crumbled in the hand. When suddenly cooled, ordinary sandstone shows very little exterior evidence of injury, while granite usually flakes off at the corners. Very fine grained granite may show cracks without flaking. stone which has been heated to a high temperature emits a characteristic ring when struck with metal. When scratched it emits a sound similar to that of a soft burned brick. This may be due to the loss of the water of composition by the minerals composing the rock..

“Experiments which have thus far been performed seem to indicate that few, if any, stones will withstand, uninjured, a temperature of 1500° Fahrenheit. The stone which is least injured is apparently the one which has the simplest mineralogical composition and the most uniform texture.

“A careful series of experiments, showing the loss of strength by each increase in temperature of 100° to 200° for the different kinds of building stones, would be both interesting and useful. To my knowledge such experiments have not thus far been performed.

“Effect of Sulphurous Acid Gas and Dilute Sulphuric Acid. - The only kinds of stone which are to any degree affected by Sulphurous acid gas or dilute Sulphuric acids are those which contain calcium carbonate or calcium magnesium carbonate. The effect of sulphurous acid gas is determined by placing two-inch cubes which have been carefully dried at a temperature of 110° C. in a wide mouthed bottle in which the air is kept moist by a beaker of water. The bottle should be sealed and sufficient sulphur dioxide transferred into it each day to saturate the atmosphere. The samples should remain in the bottle for thirty o forty days, and the atmosphere should be kept saturated with sulphur dioxide. After this, the samples should be removed, washed thoroughly and dried at a temperature of 110° C. The loss in weight should then be determined and the percentage which this is of the original weight of the cube is a measure of the effect of the gas.

“The loss in weight is due mainly to the removal of calcium and magnesium salts which collect at the surface and are taken into solution when the samples are washed in water. In the case of dolomite the samples sometimes swell and crumble. If such samples are weighed before washing they will be found to have increased in weight, as a result of the change of the magnesium carbonate to magnesium sulphate.

“Effect of Carbonic Acid Gas. - Carbonic acid gas only affects in a measurable degree those stones which contain calcium carbonate or calcium magnesium carbonate. Two-inch cubes are used for this test. They are washed and dried at a temperature of 110° C., after which they are placed in a wide mouthed bottle which is filled with carbonic acid gas. The atmosphere in the bottle is kept moist with a beaker of water. After being treated for a period of thirty or forty days, the samples are removed, washed, dried and weighed. The percentage of los sin weight is taken as the result.

“It is probable that sulphur dioxide and carbon dioxide do not at any time exist alone in the atmosphere. The effects of these gases acting together, or in conjunction with the many less abundant gases, may produce results which are very different from those obtained for the gases separately in the laboratory experiments.”

Chapter IV.

A Brief Geological History of Missouri

“The conception of scientific men as to the origin of the earth and as to the position and shape of the original land surface, varies so widely as to make one hesitate somewhat in making statements relative to the early history of any portion of this continent. It has been believed by men of high authority that the North American continent existed at the earliest time with essentially the same outline that it has today. The forces of destruction and construction must have been operating at that time as they are today with greater or lesser activity. Orographic movements undoubtedly resulted in the formation of mountain ranges as stupendous as those which we know at the present time. There must have been orifices at the surface of the earth through which molten rock was extruded in the manner in which volcanoes are at the present time pouring out lava in other parts of the world. the volcanic activity on the continent as a whole was probably grater than it is today. At least there is evidence that the interior portions of the continent were, during this earliest period, the scene of volcanic activity such as is not known on the North American continent today. That Missouri had a part in this activity is shown by the rocks which are exposed in the southeastern part of the State.

“Modulus of Elasticity. - The modulus of elasticity is synonymous with coefficient of elasticity, and is sometimes defined as the weight that would be required to stretch a rod one square inch in cross section to double its length. The result is usually expressed in pounds per square inch. It is ‘valuable in determining the effect of combining masonry and metal; of joining different kinds of masonry or

“The oldest rocks of which we have any knowledge are banded schists and gneisses which are classed with the metamorphic rocks. These rocks usually show evidence of intense folding and fracturing and seldom constitute desirable stone either for building or ornamental purposes. Frequently they have been so altered through metamorphic processes as to render their original texture and composition unrecognizable. These rocks belong to what is known as the Archean system. Many of the igneous and metamorphic rocks of this continent are younger in age than the Archean, although up to within a few years ago, it has been the practice to classify all the rocks which are of pre-Cambrian age as Archean.

“In Missouri it has not been possible thus far to separate the Algonkin from the Archean. the igneous rocks are known to be of pre-Cambrian age and they have so very few of the characteristics of the typical Archean as lead one to believe that they are chiefly Algonkin. In the southeastern part of the state, chiefly in St. Francois, Madison, Iron, Washington, Reynolds, Wayne and Shannon counties, there are areas of igneous rocks, chiefly granite and rhyolite, which have been intruded by diabase dikes. None of these rocks, with the exception of a small area at Pilot Knob, are of known sedimentary origin. If Missouri was submerged beneath the ocean at any time during the Algonkin period, there is little evidence of it at the present time. This part of the continent was apparently above the sea and may have consisted of lofty mountain ranges beneath which formed the massive granite bosses, which, after millions of years of exposure to the agents of weathering, are now exposed at the surface. The igneous rocks, which, for want of more positive knowledge, will be spoken of as pre-Cambrian in age, consist chiefly of granite and porphyry. The granite has either a gray or light to dark red color. In some places it is very fine grained and in others it is coarse, frequently porphyritic. The rhyolite has a black to red color and consists of a fine grained groundmass through which are scattered porphyritic crystals of feldspar. In some places the granite apparently grades into the rhyolite, there being no sharp contact between the two. It is understood, however, that the granite has been formed by the solidification of a molten magma deeply buried beneath other rocks. The cooling of the magma must have gone on slowly enough to permit the complete crystallization of all the mineral matter which it contained. These rocks are spoken of as being holocrystalline and as having a granitic texture. The individuals of quartz, feldspar and biotite or hornblende are intricately interlocked, giving the rock a strength seldom attained by those that have formed through sedimentation.

“The rhyolite, commonly known as porphyry, formed under conditions which permitted only a partial crystallization of the magma. It is thought to have formed near or at the surface of the earth, which resulted in much more rapid cooling than in the case of the granite. Originally, the rhyolite had a glassy or vitreous groundmass, studded with crystals of feldspar. This groundmass is now finely crystalline as a result of changes which have been going on within the rock since it was formed.

“Owing to its finer texture, the rhyolite has suffered more from earth movements than the granite. It is much more brittle, breaking more readily under stress. This has resulted in the production of many joints in the rhyolite while there are relatively few in the granite.

“Together the granite and rhyolite constitute an almost inexhaustible supply of excellent rock for building, monumental, paving and other purposes for which granite is used.

“The first rocks which are of known sedimentary origin belong to the Cambrian period. This system of rocks is so closely associated with the overlying Ordovician beds, in most parts of the State, as to render impracticable a separation of the two at the present time. The beds which belong to the undifferentiated Cambrian and Ordovician periods are known together as the Cambro-Ordovician. These undifferentiated formations consist of sandstone and dolomite, aggregating from 800 to 1,000 feet in thickness.

“The oldest formation of this series is exposed in the central part of the State and is known as the Proctor (Fourth Magnesian) limestone. This does not rest directly upon the granite. Drill records show that beneath this limestone there is a sandstone and perhaps another limestone formation. The Proctor formation consists of heavily bedded dolomite. It has a very uniform texture, but contains occasional irregular hackly cavities lined with dolomite, calcite and quartz, which might injure the stone more or less when cut and dressed for building purposes. The beds also contain occasional, promiscuously disseminated nodules of chert. The stone is crystalline and medium to coarse grained and has a bluish gray tint. This formation is only exposed in those places where the stream channels have cut deep into the Ozark plateau or local folds have brought the beds near the surface.

“This formation contains a great quantity of stone which is admirably adapted to the rougher forms of masonry construction.

“Above the Proctor formation is a thickness of from six to thirty feet of sandstone known as the Gunter (Third Sandstone). It appears that after the deposition of the Proctor limestone, this portion of the continent was elevated above the ocean. For an apparently short interval erosion and other forces of weathering were engaged in cutting down and trenching the land. This period was of short duration and the ocean soon covered this portion of the continent again, depositing the sandstone which now constitutes the Gunter formation.

“This sandstone is fine to coarse grained, has white to yellowish color and is rather soft. It is usually well bedded, frequently cross bedded. the areal distribution is comparatively limited, the exposures being confined to a few localities on the northern flanks of the Ozarks, where folding combined with erosion has brought the beds to the surface, and to limited areas after the flanks of the St. Francois mountains in the southeastern part of the state.

“This formation in the central Ozark region may be the same as the LaMotte sandstone described n the earlier reports of this Bureau, as occurring unconformably above the pre-Cambrian in the southeastern part of the State. However, there is considerable evidence that it is the equivalent of the shale and conglomerate horizon between the Potosi and Bonne Terre formations. The field work of this season will probably settle this point.

“Very little of this stone is quarried owing to the abundance of better and more easily accessible stone with which it is usually associated.

“Following the deposition of the Gunter sandstone somewhat deeper water prevailed and there was deposited a series of dolomite beds, known as the Gasconade formation (Third Magnesian limestone), in the central Ozark region. Providing the Gunter and LaMotte sandstones are the same, the Bonne Terre limestone or a part of it must be the continuation to the southeast of the Gasconade limestone of the central Ozark region. There is considerable difference between the Gasconade and Bonne Terre limestones. The Gasconade limestone has a thickness of from 240 to 250 feet in Miller county where it is typically exposed, while the Bonne Terre limestone in the southeastern part of the State is often between 500 and 600 feet thick. The Gasconade limestone contains an abundance of chert, either in layers or as disseminated nodules, while the Bonne Terre limestone contains no chert. On the other hand, the Bonne Terre limestone contains numerous thin layers of shale, usually in what are known as shaly horizons, while the Gasconade limestone contains practically no shale. In case the Gunter sandstone provides to be the equivalent of the shale and conglomerate horizon between the Potosi and Bonne Terre, then the Gasconade and Potosi formations must be the same. These formations correspond more nearly in composition and thickness than do the Gasconade and Bonne Terre.

“There are many beds in this formation from which stone suitable for bridge abutments, foundations and other forms of rough masonry may be quarried. Blocks of large dimensions may be obtained. This formation has a wide distribution over the Ozark plateau region.

“Above this formation and conformable with it there is a series of alternating sandstone, chert and dolomite beds known in the central Ozark region as the St. Elizabeth formation. This may be the equivalent of the cherty horizon of the Potosi formation of the southeastern part of the State. Both the St. Elizabeth and Potosi are highly siliceous, dolomite formations containing massive beds and nodules of chert and beds of sandstone. In the Potosi formation there is very little sandstone. It has been observed chiefly at the top of the formation as exposed in Washington county. If the St. Elizabeth and Potosi formations are not the same, then the former is above the latter and is represented in the southeastern part of the state by the sandstone, chert and dolomite beds which occur at the top of the Potosi. In many places the dolomite is very subordinate. In the central Ozark region the St. Elizabeth contains locally thick beds of coarse to fine grained sandstone which occur in lenses at different horizons in the formation. This formation has a very wide distribution throughout the Ozark plateau region.

“Throughout the Ozark region the sandstone of this formation is quarried for buildings and sidewalks. It is medium to coarse grained, thickly bedded and has a reddish brown to yellow color. It is moderately hard and is considered one of the best and most durable sandstones in the State.

“Above the St. Elizabeth formation and conformable with it is a series of dolomite beds known as the Jefferson City formation (Second Magnesian limestone). This formation consists of thick beds of siliceous, pitted dolomite alternating with thin beds of arenaceous, argillaceous dolomite. The thick siliceous beds are known as “pitted dolomite,” while the argillaceous beds are known locally as “cotton rock.” This formation occupies the more elevated parts of the Ozark plateau and is therefore more readily accessible to the quarryman than those underneath. This formation is beautiful exposed along the Missouri Pacific railroad between Washington and Jefferson City.

“A great part of the stone used in the Ozark region is quarried from this formation. There are very few large quarries, but hundreds of small ones from which stone is obtained for local consumption.

“After the deposition of the Jefferson city limestone this portion of the country was elevated above the sea, and eroded. It is uncertain whether this interval was short or long. It is known, however, that the land was eventually submerged, and that above the Jefferson City limestone there was deposited a considerable thickness of sandstone constituting what is now known as the Pacific or First sandstone. It is thought that this is a continuation of the St. Peters sandstone of Minnesota, Illinois and Iowa.

“As a rule, this sandstone is soft and medium to coarse grained. IN some places it is remarkably pure, being 99 per cent silica. It occurs chiefly in the eastern part of the State, being found only in small isolated areas over the Ozark plateau. It has a variable thickness, there being in places one hundred or more feet exposed.

“Above the pacific sandstone a series of limestone beds were laid down, known as the Joachim formation or First Magnesian limestone. These beds have a very limited areal distribution, being best exposed in that section of the State lying between Crystal City, pacific and Klondike. This formation contributes very little if any to the quarrying industry.

“Throughout these formations there is a comparatively meager fauna. In the Gasconade and St. Elizabeth formations there are remains of brachiopods, trilobites and corals, while in some parts of the LaMotte sandstone one finds small lingual shells. Fossil remains of brachiopods and gastropods have also been observed in some of the other Cambro-Ordovician formations, but they are not abundant.

“In the eastern part of the State, along the Mississippi river, there are limestone and sandstone beds which are of known Ordovician and Silurian age. Of the Ordovician there have been recognized beds of Trenton limestone and Hudson River shale; of the Silurian, the Niagara and Lower Helderberg are the most prominent members.

“In the eastern part of the State, along the Mississippi river, there are limestone and sandstone beds which are of known Ordovician and Silurian age. Of the Ordovician there have been recognized beds of Trenton limestone and Hudson River shale; of the Silurian, the Niagara and Lower Helderberg are the most prominent members.

“These strata have not been positively recognized in the western part of the State. The greater part of the Ozark region, at that time, may have belonged to the land area.

“The Trenton and Niagara limestones are quarried at a number of places, the stone being used for building purposes. The Trenton limestone is in places very pure, being 99 per cent. calcium carbonate. The Niagara is impure, being somewhat arenaceous.

“At the close of the Cambro-Ordovician period it is thought that at least the southern and western portions of Missouri were elevated above the ocean, becoming a part of the continent. The distribution of Silurian and Devonian strata in the western southern parts of Missouri has never been determined. Devonian and Silurian limestones occur in the northern and eastern portions of the State, and in most places are conformable with the underlying Cambro-Ordovician.

“Wherever the Devonian has been observed, it is apparently conformable with the overlying Mississippian (Lower Carboniferous) system. The thickness of the Devonian has never been definitely determined, but probably does not exceed, at the place of its greatest development, 300 feet. It attains its greatest thickness along the Mississippi river between St. Louis and Hannibal. It thins rapidly to the west, being doubtfully present in the southwestern part of the State. The limestone of which this formation is composed is argillaceous. Whether or not this formation ever covered the region known as the Ozark plateau is unsettled.

“The Mississippian or Lower Carboniferous series has a maximum thickness of from 1,500 to 1,600 feet.* It consists of several different series of rocks, among which Swallow and Broadhead distinguished the Chemung, Burlington (including the Keokuk), St. Louis and Chester. The rocks comprising the Chemung series are chiefly limestone, sandstone and shale. Occupying a subordinate position in this series is the formation known as Lithographic limestone. The Chouteau limestone, also a member of this series, is quarried in some sections of the State, as is also the Vermicular sandstone. However, none of the stone from this series occupies an important place in the quarrying industry.

(page 57 footnote: The estimates of thickness of strata, as given in this chapter, are taken from the work of the earlier geologists and are not the results of our own observations.)

“The Burlington limestone is a very important building stone. It also constitutes one of the chief sources of limestone used in the manufacture of quick lime. The quarries at Carthage, Phenix, Hannibal, Louisiana and other places are located in this formation. This limestone is in some localities remarkably white. It is exceptionally high in calcium carbonate, frequently containing over 99 per cent. The St. Louis limestone, which overlies the Burlington, is the chief source of rubble and crushed stone for St. Louis and vicinity. It has a thickness of about 250 feet, but a comparatively limited Surficial distribution.

“The rocks of the Mississippian system outcrop over an extensive area in northeastern and southwestern Missouri, surrounding the Cambro-Ordovician, Silurian and Devonian rocks of the Ozark plateau. An idea of the area covered by the rocks of this system can best be obtained by reference to the geological map accompanying this report. The sea in which these rocks were laid down supported myriads of Marine animals, the shells of which make up a greater part of some of the beds of this formation. The Burlington limestone is in some places a mass of crinoid remains. so thickly is this limestone studded with fossils that it was called by the early geologists the ‘encrinital.’