Quarries in Missouri & Quarry Links, Photographs, and

Articles

Carthage Area Quarries (General)

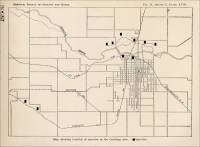

- Carthage, Missouri – Map showing Location of Quarries in the Carthage Area, Plate XVIII. (Quarries) (Map from The Quarrying Industry of Missouri, by E. R. Buckley, Director and State Geologist, and H. A. Buehler, Missouri Bureau of Geology and Mines Vol. II, 2nd Series, 1904.)

-

Carthage, Missouri – Also see: “North Carthage, Missouri.”

- Carthage, Missouri – the Town of Carthage & its Manufacturing & Business

Interests (Excerpt from Historical and Descriptive

Review of Missouri, Vol. 1. The Central and Southwestern Sections,

Kansas City: Jno. Lethem, 1891)

“In the county seat of Jasper county and at present (circa 1891) has a population of 8,000, rapidly increasing, as Southwest Missouri fills up. It is just about the geographical center of the county and is well built, healthy, beautifully situated on the hills on the southern banks of the Spring River a most lovely spot nestling in the forest shade. The river itself is a clear, cool, rapid stream, rolling over a pebbly bottom and having its source in innumerable springs high up among the hills. Everywhere is evidence of a city where people are industrious, thrifty, intelligent and progressive. It has splendid parks, shady groves, fine residences, substantial business blocks and an air of life and business activity....”

“...The city has free mail del ivery system since 1889, the only town in this section entitled by its volume of business to this luxury. The total assessable valuation of Carthage for 1891 was over $2,000,000, which is about one-third its actual wealth. A telephone exchange connects all the mining towns of the county with Carthage. Its manufacturing and business interests are represented by four large flouring mills, two extensive woolen mills, one of which manufactures all its output into clothing. A foundry and machine shop making a specialty of heavy mining machinery - plenty of business for additional plants in this line. A fruit and vegetable canning factory with a capacity of 16,000 cans per day, a fruit evaporator with a capacity of 500 bushes daily. Two planing and sash factories, a plow factory, four wagon and carriage factories, one ice and cold storage plant, a creamery, a fair ground - with a race track, on which was expended $26,000, - two parks, six lime kilns, capacity 850 barrels daily; hundreds of car loads of this lime are annually shipped to Kansas, Nebraska and Texas. Six large marble quarries, one of which shipped upwards of 700 cars to St. Louis and Kansas City ; this plant alone costing $75,000. The demand for the stone cannot be supplied and there is room for a dozen more plants. The stone, for its quality of finish, durability and beauty, is unsurpassed and its quantity inexhaustible....”

-

Carthage, Missouri - The Carthage Area Stone Quarries (circa 1904 and before) (The following information is from The Quarrying Industry of Missouri, by E. R. Buckley, Director and State Geologist, and H. A. Buehler, Missouri Bureau of Geology and Mines Vol. II, 2nd Series, 1904.)

Mississippian (Sub-Carboniferous).

“This system, which consists chiefly of limestone, has a wide distribution in the southwestern, west central and northeastern parts of the State. The stone is chiefly a white or grayish colored, coarsely crystalline limestone. It is in this formation that the Carthage quarries are located. The following are detailed descriptions of the principal quarries located in this formation.Carthage.

“The most extensive limestone quarries in Missouri are located at Carthage, the county seat of Jasper county. Although a comparatively new industry at this place, it has increased so rapidly that within eighteen years it has become the center of limestone production in this State. Today all of the quarries, with the exception of the Carthage Consolidated Co. and the Viernow and Meysenburg Lime and Cut Stone Co., are being worked to their utmost capacity and the Carthage limestone is fast becoming one of the most popular building materials in the middle west. “With the exception of the Vernon and Lime-kiln quarries, all of those in the immediate vicinity of Carthage, are north of the city, along the escarpment just north of Spring river. The Veron (sic) and Lime-kiln quarries are located just south of Spring river near the northwest limits of the city. In addition to this, two quarries have been opened about five miles southwest of the City. All of these are included within the Carthage area and the stone which is produced is known as Carthage limestone. The following is a list of the quarries in this area:Carthage Marble and White Lime Co.

Carthage Stone Co.

Carthage Quarry Co.

Viernow and Meysenburg Lime and Cut Stone Co.

Spring River White Lime Co.

Spring River Stone Co.

Carthage Building Stone Co.

Myers Stone Co.

Carthage Consolidated Quarry Co.

“For many years this stone was quarried by hand and used for foundations, caps and sills in buildings in and about Carthage. It was also used for bridge abutments on the Missouri Pacific railroad near the city. The first quarrying machinery was introduced about 1885, since which time the stone has gained an almost national reputation. “Geologically, this limestone belongs to the Burlington division of the Mississippian or Lower Carboniferous. The formation obtained its name from Burlington, Iowa, where it is typically developed. The Mississippian outcrops on a broad irregular belt across the middle of the State, in a northeast-southwest direction. Near the central portion of the State, it occurs as a narrow belt of limestone broadening both to the southwest and northeast where it covers extensive areas. “The typical Burlington formation usually consists of heavy beds of brown and gray to white, coarsely crystalline limestone. Abundant remains of mollusca and crinoidea occur in this formation, some portions of which are made up chiefly of the remains of crinoidea. From an economic standpoint, it is the most important limestone formation in the State, being extensively quarried at Carthage, Hannibal, Springfield, Phenix, Ash Grove, Peirce City, Walnut Grove, Osceola and other places. At Springfield, Ash Grove and Pierce City it is used chiefly for the manufacture of quicklime and at Hannibal, Phenix and Carthage it is quarried extensively for building stone. “At Carthage this stone as it occurs in the quarry has a slightly bluish gray tint, the upper beds being whiter than those deep in the quarry. When cut and dressed, the stone is white. Nowhere is the color of the stone more uniform in the different quarries than in the Carthage area. The bluist tint observed in any of the stone was in blocks which had been quarried from the two lower channel cuts of the west opening of the Carthage Marble and White Lime Co. Even this stone, when rock-faced or sawed, has just enough of a blue tint to take away the monotony of a dead white. The faint blue tint gives the stone a life, which a dead white rock does not have. In uniformity of color this is the peer of limestones. In comparison, the Bedford, Indiana, stone is so far inferior as not to warrant consideration.

“The calcite grains are closely interlocked, giving the stone strength and durability. A thin section of this stone, examined under the microscope, shows it to consist mainly of irregular grains of calcite of medium size, cemented together with a calcite matrix. The calcite has a dull grayish color in ordinary light. The faintest possible tinge of iron oxide was observed in two or three parts of the section. However, it is not sufficiently abundant to give color to the stone. No quartz or other minerals of importance were observed. No minerals that might cause discoloration through decomposition were observed. The freedom of the stone from impurities is shown by the following chemical analysis made in the laboratory of this Bureau.Insoluble -.69

Oxides of Iron and Alumina (Fe2 O3, Al2 O3 ) -.21

Carbonate of Lime (CaCO3 ) - 98.57

Carbonate of Magnesia (MgCO3) -.65

(Total) - 100.12

“Stratification planes, having the appearance of the joints in the cranium, which occur in this stone, were called suture joints by the earlier geologists. Later, these became known as stylolites. In this report we have chosen to call them suture joints. In the Carthage limestone, suture joints occur parallel to the bedding and are from two to twenty inches apart. They vary greatly in size, some of them being as much as four inches deep. The smallest of these joints are tight and the stone cannot be split along them as one might suppose. The larger of these joints are frequently open and along them the stone is usually easy to split. These seams injure the appearance of the stone when they occur on a sawed face. To avoid this, the stone is generally sawed parallel to the bedding and laid on edge in the wall. The so-called number one stone, or monumental stock, contains none but the very finest suture joints. An examination of the outcrops show that these joints will open after long exposure to the weather, separating the stone into thin layers. “In certain parts of the quarries, tar seams or joints occur in the stone. Some of the quarries are almost entirely free from them, while in others, they appear to be restricted to very limited areas. They consist of vertical or slightly inclined joints which contain bituminous material, which appears on the surface of the stone as a black line or dark streak. Stone containing these seams is rejected by contractors and consequently this discoloration may become a source of considerable loss. “Compared with the Bedford oölitic limestone, the Carthage stone is much more difficult to cut and dress. Two inches per hour is about the average work that can be done in sawing this stone. It has a much lighter and more uniform color than the Bedford stone. It is considerably stronger than the Bedford stone, as is shown by the strength tests given in the table in the appendix.* (* Please note that the appendix of this book referred to in the above paragraph will not be presented in this document. If you would like a copy of the tests, feel free to contact me. Peggy B. Perazzo.)

“The stone polishes nicely and is used quite extensively in monumental work. The difficulty in obtaining large pieces free from suture joints is the greatest drawback to its use for monuments. “Lenticular and roundish nodules of flint occur in different parts of this formation. They are not scattered promiscuously through the stone, but occur at definite horizons in the formation. These nodules vary in size from several inches to three feet in their greatest diameter. Normal to the bedding planes, they are not usually over ten inches in thickness. As a rule, they do not form a continuous or connected layer. The quantity of flint varies in different quarries. Occasionally a bed contains so much flint as to make the expense of quarrying very great. (See description of the old quarry of the Carthage Marble and White Lime Co.) The floor of most of the quarries is a bed of flint nodules. These beds of flint nodules do not occasion very great waste since the blocks of stone are usually lifted along them. “The Carthage limestone has no protective layer above it and solution has decomposed the stone along the jointing planes. Due to this process of decomposition, the surface is usually very rough and bouldery. The open seams are filled with clay and are known throughout the district as mud seams. “Improved machinery is in use in all the quarries. The Sullivan improved Y channeler is being tried in a number of these quarries. This machine will channel up to 150 linear feet per day.”

- Carthage, Missouri - “Carthage Limestone: Its Production and Characteristics,” by R. S. Strong, M.E., in Mine and Quarry Magazine, February, 1908, Sullivan Machinery Co., Chicago, pp. 179-182.

-

Carthage, Missouri – Carthage Limestone & Marble (circa 1916) – Excerpts from “Some American Marbles,” in Stone: An Illustrated Magazine, March 1916, Vol. XXXVII, No. 3, pp. 143-145. (This magazine is available in Google Book Search – Full View Books.)

“Recent conditions in Europe have caused a decrease in imports of marble into the United States. Building activity in this country is also dull, but with the general revival of business it is to be expected that building operations will increase again and accordingly that there may arise a demand for domestic marble to supplement the decreased supply from abroad. There are several domestic marbles and limestones, suitable some for interior decorative work and some for exterior work also, that are entitled to broader recognition than they have heretofore received, writes G. F. McLoughlin in the Bulletin of Mineral Research for 1914, just issued by the United States Geological Survey. Some of these marbles have been used for a considerable time and others have been quarried only during the last two or three years….”

“Among the Central States west of Mississippi River limestone and marble suitable for interior decorative work are quarried in Arkansas, Missouri, Minnesota and Texas ….”

“The Carthage stone of Missouri, although long known and used as a limestone in the Central States, has, during the last ten or twelve years, been used in polished slabs for interior work and deserves recognition as a marble. It is also sold for marble floor tiles. It is a semicrystalline to crystalline gray stone, traversed parallel to the bedding by sutures or ‘crow-feet,’ and has an appearance somewhat like that of the gray Tennessee marble. Its suture lines, however, are mostly straight, rather than wavy, and are less attractive. For this reason slabs are usually sawn parallel to the sutures….”

-

Carthage, Missouri – “Carthage Limestone and Marble” (circa 1918) (excerpt from Stone: An Illustrated Magazine, May 1918, Vol. XXXIX, No. 5, pp. 228-229)

Carthage Limestone and Marble

“Missouri, which ranks second to Indiana in the production of limestone for building and which showed gains of 17 and 25 per cent, respectively, in value of output in 1915 and 1916, suffered a decrease in 1917, according to figures compiled under direction of G. F. Loughlin, United States Geological Survey, Department of the Interior. This decrease was due to decline in sales in the Carthage district, Jasper County, which has furnished 65 to 75 per cent of the limestone for building sold in the State in recent years. The decrease, which was caused by curtailment of building operations due to the war, began in the spring of the year and has since reached a point where erection of permanent high-grade buildings by private interests is now practically at a standstill. Selling prices increased slightly in 1917 but were not sufficient to offset the increased cost of production.

“The total value of the limestone and marble sold in the Carthage district in 1917 was $392,443, representing a decrease of 28 per cent compared with 1916 and of 5 per cent compared with 1915 but exceeding the total of any other year. The output of building stone, the principal product, amounted in 1917 to 313,904 cubic feet, valued at $302,411, a decrease of 36 per cent in quantity and 39 per cent in value compared with 1916. The quantity of building stone sold in 1917 was less than in any of the nine preceding years except 1914; the value in 1917, however, was exceeded in only four years, 1909, 1910, 1915, and 1916.

“Of the total quantity of building stone sold in 1917, 219,940 cubic feet, valued at $160,350, was rough, and 93,964 cubic feet, valued at $142,061, was dressed or manufactured stone. The proportion of stone dressed by the producers increased greatly in 1915 and 1916, owing largely to the quantity required for the new State Capitol of Missouri. The proportion of dressed stone sold in 1917, though less than in the two preceding years, was greater than in earlier years.

“The production of monumental stone in 1917 amounted to 49,819 cubic feet in quantity and 167 per cent in value compared with 1916, the first year in which figures for monumental stone were separately recorded. This increase was in keeping with the conditions of the monumental-stone trade throughout the country and reflected the continuation of the prosperity for a large part of the country which was so conspicuous in 1916. All the monumental stone was sold rough by the producers.

“Of the minor products of the Carthage quarries in 1917, flagging amounted to 8,228 square feet, valued at $1,387, a decrease of 18 per cent, and rubble to 1,139 short tons, valued at $1,030, a decrease of 61 per cent. Stone for sugar factories, amounting to 3,169 short tons, valued at $1,491, is included under ‘Other stone,’ and other important items under this heading are stone for glass factories, fluxing stone, crushed stone for concrete, and pulverized stone for agriculture. The total value of these products, valued at $31,223 in 1917, increased 56 per cent as compared with 1916.”

- Carthage, Missouri – Carthage Limestone

Industry (circa 1919) – Excerpts from “Carthage

Limestone Industry,” in Stone: An Illustrated Magazine,

June 1919, Vol. XL, No. 6, pp. 268-269. (This magazine is available

in Google Book Search – Full

View Books.)

Carthage Limestone Industry

“The total quantity of limestone used for all purposes produced in the Carthage district, Jasper County, Mo., in 1918 was practically the same as in 1917, although the value of the output decreased 13 per cent, according to statistics furnished by the producers to G. F. Loughlin, United States Geological Survey. The total sales in 1918 were 70,820 short tons, valued at $339,898; in 1917, 70,600 short tons, valued at $392,443.

“The Carthage district ranks next to the Bedford-Bloomington district, Ind., in the production of limestone used for building, although its output in building stone was only 1 per cent of that of the Indiana district. The quantity of building stone reported is the smallest since statistics showing quantity have been complied (sic) by the Survey, and the value is less than that of any preceding year except 1913 and 1914.

“Of the total output of the district in 1918, 263,272 cubic feet (about 21,770 short tons), valued at $271,216, was high-grade building and monumental stone. The output of this class of stone in 1917 was 363,723 cubic feet (about 30,000 short tons), valued at $361,220, a decrease of 27 per cent in quantity and 25 per cent in value for 1918. The stone sold for building 1918 amounted to 236,885 cubic feet, valued at $239,418, a decrease of 25 per cent in quantity and 21 per cent in value. These decreases in percentages are strikingly less than corresponding decreases in the Bedford-Bloomington district of Indiana, which were 60 per cent in quantity and 44 per cent in value. The average price per cubic foot for building stone was $1.01 in 1918, 5 cents more than in 1917. Of the building stone sold in 1917, 93,964 cubic feet, valued at $142,061 - $1.51 per cubic foot – was dressed stone, whereas in 1918 the dressed stone reported as sold amounted to only 37,861 cubic feet, valued at $71,760 - $1.90 per cubic foot. This decrease of 60 per cent in quantity of dressed stone sold tended to reduce the total value for the district. The rough building stone decreased from 219,940 cubic feet, valued at $160,350 – 73 cents per cubic foot – to 199,024 cubic feet, valued at $167,658 – 84 cents per cubic foot.

“The stone sold for monumental work, which amounted to 26,387 cubic feet, valued at $31,789, decreased 47 per cent in quantity and 46 per cent in value. The average value was $1.17 in 1917 and $1.21 in 1918. Stone classified by the quarrymen as marble and included in the total amounted to 110,011 cubic feet, valued at $131,023.

“Eight companies, one more than in the last six years, reported operations in 1918. These were the Carthage Building & Stone Co., Carthage Marble & White Lime Co., Carthage Quarry Co., Consolidated Stone & Marble Co., The Missouri Quarries Co., the Spring River Stone Co., the Carthage Crushed Limestone Co., and the Independence Gravel Co., all of Carthage. The statistics given do not include the value of the rough stone sold by the quarrymen for crushing; the value given for this stone is its value after crushing. The producers that made statements regarding trade conditions in 1918 reported that business was poor and unsatisfactory, with little demand and labor scarce and high, costing 25 per cent more than in 1917. Supplies were also reported as 25 per cent higher. The principal trade change reported was the taking over by the Missouri Quarries Companies of the quarry operated during the last few years by John Gill & Co. The Carthage stone is sold principally in Missouri and the neighboring States of Arkansas, Oklahoma and Kansas, but it has also been shipped west to California, east to New York, north to Illinois, Wisconsin, Michigan, Minnesota, and Canada; south to Beaumont, Dallas and Houston, Texas, Texas (sic).

“Though the building and monumental stone sold in the Carthage limestone district amounted to 70 per cent of the total value, nearly 65 per cent of the total quantity sold in the form of broken, crushed, and pulverized limestone and a small quantity in the form of flagging. The total quantity of flagging, rubble and crushed and pulverized stone sold in 1918 was 49,095 short tons, valued at $68,682; in 1917 it was 35,594 short tons, valued at $31,223, an increase of nearly 38 per cent in quantity and of nearly 120 per cent in value. The average price per ton of this stone in 1918 was $1.40; in 1917 it was 88 cents. Of the quantity stated above 2,850 short tons, valued at $1,814, represented sales of rubble, 22,902 short tons, valued at $42,819, was stone sold to smelters, sugar factories, glass works, and powder mills; for agricultural use, and, as a substitute for whiting or chalk, or for filler, principally in the manufacture of soap, paint, putty, talc, and rubber; and the remainder was sold for flagging, concrete, and road metal.”

- Carthage, Missouri - Railroad Spurs to the Quarries circa 1898 (from Stone Magazine, February 1898, Vol. XVI, No. 3, pp. 304)

“The Carthage (Mo.) Press says that the Frisco is quietly laying its plans to build a spur to the quarries north of the river, and that two surveys for that purpose have been made, one of which was completed a couple of days ago. It is known that at least one of the quarries north of the river is very anxious to have the Frisco built to it, and it is probable that both are. It is said that both spurs may be built, the east one to reach quarry land near Kellogg’s springs likely to be opened up soon. Forty acres there are owned by Mrs. Newell, Dr. Caffee and Mr. Plummer, of Pennsylvania. George Stebbins also owns forty acres. Plans are on foot to open up this land, but nothing definite is at present ready for publication. Dr. Caffee informed a Press reporter that he had the right of way for a Missouri Pacific spur to the quarry land referred to, procured several years ago, and that he expected both a Pacific and a Frisco spur would be built there some day. He thinks it highly probable that a quarry will be opened up on the land in which he is interested between this and spring.”

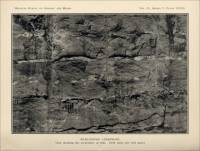

- Carthage, Missouri – Burlington Limestone (photograph from The Quarrying Industry of Missouri, by Ernest Robertson Buckley and H. A. Buehler, 1904)

- Carthage, Missouri - “Carthage Marble,” photographs available on the web site “Building Stones of the United States - the NIST Test Wall” web site. (All of the stones from Missouri that are included in the test wall are available in the Missouri section of the web site.)

Photographs of the archived “Carthage Marble” limestone sample and a photograph of the same type of stone in position in the NIST test wall are available on this web site.

- Carthage, Missouri - “Early Lime Works in Carthage,” Excerpt from Missouri Mining Heritage Guide,

by John R. Park, Stonerose Publishing Co., Miami, Florida, March 2005. (The following excerpted quotations are used with the permission of John R. Park, author.)

Early Lime Works in Carthage

“Even before dimension stone was commercially produced in Carthage (...Carthage Marble Quarry), the local limestone was quarried for lime production.

“Almost in-town, the Spring River White Lime Company began operations in 1882 with a single natural-gas-fired lime kiln. The site of the limeworks is described as ‘west of Main Street and southwest of the St. Louis & San Francisco depot’.

“The Jasper County Stone & Lime Company began operation, along the bluffs of the Spring River north of Carthage, ca 1875.”

Commercial use of material within this site is strictly prohibited. It is not to be captured, reworked, and placed inside another web site ©. All rights reserved. Peggy B. and George (Pat) Perazzo.