California Stone Industry (historical account up to 1966)

Excerpts From

Mineral Resources of California, Bulletin 191,

California Division of Mines and Geology, San Francisco,

California, 1966.

(Please note: Use the drop down box below to jump to the individual sections of this document.)

The Mineral Industry of California, by Ian Campbell, Chief, California Division of Mines and Geology, San Francisco, Calif.

"In 1965, 117 years after John Marshall's historic discovery of gold at Sutter's mill, the California legislature enacted a bill (SB 265) designating native gold as the office 'State Mineral.' In the same bill, the legislature designated serpentine as the official 'State Rock.' The one designation may be somewhat overdue; the other is assuredly timely. For in 1852, only four years after Marshall's discovery, California's gold production reached a total of more than $81,000,000 (at the current price of gold, this would be almost $140,000,000), a figure never since equaled. In that year serpentine was virtually unnoticed - except as 'hungry rock,' i.e., known to be barren of gold and therefore something to be shunned by prospectors.."

"Important as all of these metallic minerals have been, and are, they constitute today (circa 1966) only a very minor part of California's mineral industry. Almost unheralded, the industrial minerals ('nonmetals') long since overtook the metals in terms of value in the State's economy.The figures stand today at more than $500,000,000 annually for the industrial minerals, versus slightly less than $60,000,000 for metals. And the trend of the industrial minerals has been steeply upward for over twenty years.."

"If the history of California borax mining provides contrasts with gold, other industrial minerals provide additional contrasts-with both gold and borax. This is particularly true of the construction materials, especially rock, sand and gravel. These are commodities that, unlike gold and borax and many other minerals, depend for their demand on density of population more than upon special qualities and rarity of occurrence. And these are commodities which, because of their bulk, seldom enter significantly into interstate-much less international-commerce. They are therefore relatively immune to the effects of changing tariffs, subsidies, import quotas, and international cartels, and to this extent provide a less fluctuating and a sounder element in the mineral economy. Yet sand and gravel, except such as was mined incidental to the recovery of gold, did not even figure in the early records of the State's mineral production. Today, with an annual output of nearly 113,000,000 tons, valued at nearly $130,000,000, sand and gravel is the State's leading mineral industry in terms of volume, and shares with cement the top place in value among the State's 'hard minerals'..."

"With the combination of men and minerals to be found in the State, the future of the mineral industry should indeed be bright. But there are many who, with considerable justification, view it with misgivings. These stem from a recognition of two trends. One of these is the growing conflict over land use. As mining turns more and more to open pit, and to larger and larger operations, more acreage is involved and more public pressure develops to insist on other uses for such acreage, whether for recreation, for urbanization, for 'wilderness,' or just 'anything but mining!' The other trend is towards lesser involvement of fewer people in the mineral industries. This results partly from changes within the industry whereby smaller operations involving in the aggregate many men, are giving way to larger operations involving huge capital outlays and often fewer men. (For example, to install the new Redding operation of the Calaveras Cement Co.- a relatively small operation, as some cement plants go - required some $16,000,000 in capital outlay. On a weekend, when the mine is shut down, the largely automated mill, which has an annual capacity of 1,500,000 barrels, can operate with only five men! And the conversion a few years ago of the underground mine of the U.S. Borax and Chemical Corp. at Kramer to an open-pit operation, and installation of a new mill, required an initial capital investment to around $20,000,000. Yet the number of miners and millmen has decreased at the same time that output was being increased.) The increasing number of mergers, and the absorption of small companies by larger in the petroleum industry is further testimony to the changes that are going on. The net effect of these trends - greatly amplified by population growth, per se - is that, whereas 100 years ago almost every Californian had some familiarity, and many were directly involved, with the mineral industry, today scarcely one in a thousand has any concept of how dependent he is, at virtually every turn of his everyday life, on the products of mines and oil wells. Far less does he have any concept of mineral industry operations, economics, or geology. It is these people who now frame the laws under which the industry must operate. It has been well said that government - Federal, State, and local - 'calls the turns' on the fortunes of the mineral industry as never before. California has most favorable geology; she has the mineral resources; she has the wherewithal for maintaining a minerals industry second to none. Will her citizens prove sufficiently knowledgeable to meet the challenge? (circa 1966) That is the question that now looms largest in California's unfolding mining history.

Mineral Resources - Introduction, by J. P. Albers, U. S. Geological Survey, Menlo Park, Calif.) (excerpts)

"The economic value of a mineral resource is determined by the cost of mining and processing, cost of marketing, including transportation to market, and by the demand for the commodity. Costs and demand vary with fluctuations in local or national economy, advances in the technological fields of exploration and exploitation, and increases in requirements by industry and the expanding population. A resource that cannot be developed profitable today may become the basis for a profitable enterprise in the future because of these constantly changing sociologic, technologic, and economic factors.."

Limestone, Dolomite, and Lime Products, by O. E. Bowen, California Division of Mines and Geology, San Francisco, California. (circa 1966) (The following are excerpts.)

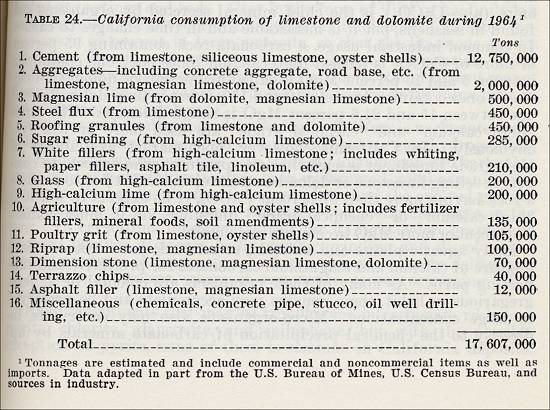

"California, the most highly populated state in the union and also among the fastest growing in population, is fortunate to have vast resources of carbonate rocks to supply its expanding industries. Her cement industry alone, largest in the United States and probably in the world, for an equivalent political unit, consumes about 13,000,000 tons of limestone and fossil seashells each year. In excess of 4,500,000 tons of carbonate rocks are consumed annually by a great number of other industries led by: aggregates for the construction industry, magnesian and high-calcium lime manufacturing, limestone and dolomite for steel manufacturing, roofing granules for the construction industry, limestone for sugar refining and limestone for glass manufacturing, as shown in Table 24. The value of carbonate rocks to the State's economy is immense, as it occurs widely distributed and is available at a relative low cost compared to other raw materials.

Table 24. California consumption of limestone and dolomite during 1964."Limestone is one of the few raw materials that are absolutely basic in modern industry and necessary to our present civilization. In addition to its major use in the manufacture of portland cement, it is the source of lime for which there are over 7,000 uses. Most of these uses depend on the caustic properties of calcium oxide or calcium-magnesium oxide produced by calcination of limestone or dolomitic limestone. In some of these uses, it serves to combine with and remove unwanted materials for a desired product as in the manufacturing of steel, and the refining of sugar and petroleum. Many of its uses are almost as old as recorded history, and because it is economical it has been widely employed."

"A great majority of California limestone and dolomite deposits occur in metamorphosed or partly metamorphosed marine sedimentary rock sequences. Most commonly, they are interbedded with non-carbonate sedimentary rocks and make up only a small part of the stratigraphic section in which they occur. In the few remotely situated parts of the State, i.e., southern Inyo and northern San Bernardino Counties, carbonate rocks do form the bulk of some sedimentary sections and reach thicknesses of more than 10,000. In contrast to many other limestone and dolomite-producing states, California deposits tend to occur in steeply dipping, structurally complex, lenticular bodies of small areal extent rather than in flat-lying or gently dipping formations of large area extent. Consequently, prospecting for limestone in California is more complex than in most other states.."

History of Utilization of Carbonate Rocks in California (excerpts)

"The use of lime-bearing materials in California dates back to the building of the Spanish missions, where witewash (sic) and lime mortars were widely used in small quantities. Abalone shells, pismo clams, and other shells obtained on the beaches were probably the first materials burned into lime. Later, accumulations of fossil shells were found and finally it was discovered that the crystalline limestones, so widely distributed throughout California, could be used. Not until the gold rush days of the early 1850's did lime become important to the construction industry in California. This rising demand was directly related to the hazardous fires which repeatedly swept through towns made of frame buildings. Field stone or brick buildings laid up in mud or in lime mortar became the standard type of construction throughout the gold country, and many of these remain in use today. A great deal of lime was imported from Europe to supply demand during the early part of the gold rush period.

"Both marble and limestone were used as structural materials in buildings as early as 1850. The marble-cutting business, once substantial in California, has almost disappeared, because high labor costs make California marble noncompetitive with marbles from Italy, Georgia, and elsewhere. Limestone has been used as railroad ballast, road metal, and the like from gold rush days, and as concrete aggregate since the turn of the century.

"The lime manufacturing business probably had its heyday between 1880 and 1900 - in relation to its importance to the then current economy, if not in actual tonnage produced. Vast banks of lime kilns were constructed in the Santa Cruz Mountains, Santa Lucia Range, Sierran foothills, Tehachapi Mountains, and the southwestern Mojave Desert. Many of the lime companies were as important for their day as the portland cement companies now are - in relation to the rest of the economy.

"Although portland cement was invented in England as early as 1824, it was not used to any great extent in California until the late 1850's and 1860's. The first cement used here was imported from Europe. Even then its use did not greatly supplant lime mortars nor did concrete become serious competition to masonry construction until about the turn of the century. This was partly due to primitive methods of making and handling cement which resulted in non-uniformity of the product. Also, it was difficult to keep dampness from deteriorating the stored cement.

"Cement manufacturing in California dates from 1860, when a hydraulic cement (a type manufactured at considerably lower temperatures than portland cement) was placed on the San Francisco market. Apparently, limestone from beds in the Martinez Formation (Paleocene) and from Pleistocene fossil seashells were blended with clay as the raw materials for this venture. The first cement approaching a true portland cement was made at Santa Cruz in a brick kiln about 1877 from crystalline limestone and clay. Another early plant that produced portland-type cement was build on the Jamul Ranch in southern San Diego County in 1891. The California Portland Cement Co. built a plant at Slover Mountain near Colton in 1895 that, although enlarged and rebuilt several times, has been in continuous operation through the present day.

"Since the early 1900's, cement plants have been the largest consumers of limestone in California, but numerous other industrial users of limestone have been equally important to the economy of California, even though the quantity of material they consume is smaller. The many chemical industries which consume limestone, for its lime content, for the carbon dioxide that can be evolved, or both, seem to have developed principally since 1900. Many had their beginnings through the impetus of World War I. Limestone was quarried for steel flux and copper refining flux as early as the 1880's, possibly as early as 1860. The use of limestone in sugar refining dates back at least to 1870 when E. H. Dyer built the first successful refinery at Alvarado, Alameda County. The glass industry, another major consumer of California limestone, was initiated by the Illinois Pacific Coast Glass Co. at San Francisco about 1897 and by the San Francisco Glass Works (1890-1898).

"Dolomite probably was first used in California as marble building stone, particularly around Sonora and Columbia in the gold country. Dolomite marble dimension stone was produced commercially in Inyo County about 1888 and may have been produced in the Sonora-Columbia areas of Tuolumne County in the 1870's and 1880's. Production of dolomite in California was intermittent and not large up to 1942. Except for durable material used as crushed stone, the commonest use for dolomite up to 1942 was as a basic flux in the manufacture of steel. In 1942, the Henry J. Kaiser interests initiated the use of calcined dolomite and seawater in the manufacture of magnesia for use in the production of magnesium metal, and in 1945 began to produce magnesia refractories. Within a decade, the other California producers of magnesia altered their processes to use dolomite. These firms are by far the greatest consumers of dolomite in California. Prior to the advent of the use of dolomite in manufacture of magnesia, it had been made by interaction of lime with sea water. Interaction of calcined dolomite with sea water gives a substantially larger yield of magnesia."

Occurrence of Limestone and Dolomite in California

"Most of the limestone and dolomite deposits in California occur in strongly deformed and metamorphosed marine sedimentary rocks. Most commonly they are of Paleozoic age although there are some of Precambrian, Mesozoic, and Cenozoic ages. Unmetamorphosed Tertiary algal limestones of good grade are found in the Eocene Sierra Blanca Formation of Santa Barbara County, and the Paleocene Martinez Formation of the Santa Monica Mountains. Oligocene (?) and Miocene shell limestone of the Vaqueros Formation is extensively quarried in San Luis Obispo County. Quarternary seashell deposits have been exploited at San Francisco, Newport, and San Diego Bays. Recent marl of caliche type has been quarried in a small way in Fresno and San Diego Counties. Chalk, an earthy foraminiferal limestone, is unknown in California.

"The principal areas where carbonate rocks are abundant and reasonably near to markets and to transportation facilities are: (1) the Klamath Mountains of Shasta and Siskiyou Counties, particularly the southeast part adjacent to Redding; (2) the foothill belt of the Sierra Nevada from Placer to Tulare County; (3) the Santa Cruz, Gabilan, and Santa Lucia Mountains of the central Coastal Ranges; (4) the Tehachapi Mountains and adjacent southernmost Sierra Nevada; (5) the Argus and Panamint Ranges of Inyo County; (6) the Victorville-Oro Grande-Adelanto vicinity of the southwestern Mojave Desert; (7) the northern San Bernardino Mountains adjacent to Lucerne Valley; (8) the Mescal, New York, and Province Mountains of eastern San Bernardino County; (9) the northern part of the San Jacinto Mountains including the Palm Springs-Lake Hemet and Beaumont-San Jacinto areas; (10) the Big and Little Maria Mountains of eastern Riverside County; and (11) the Coyote Mountains of Imperial County, largest potential source for the San Diego marketing area.

"Four formations have yielded industrial limestone in Shasta and Siskiyou Counties: the Hosselkus Limestone (Triassic), the Kennett Formation (Devonian); the McCloud Limestone (Permian); and the Gazelle Formation (Silurian). The Hosselkus Limestone extends south into the northern Sierra Nevada, but the others are confined largely to the Klamath Mountains. The Kennett and Hosselkus formations yield limestone that is predominantly blue-gray to black; the McCloud yields predominantly dove-gray rock. The Hosselkus Limestone has been metamorphosed very little and is fine grained; rock from the other three formations commonly is recrystallized and ranges from fine grained to medium grained. None of these formations has yielded white rock of high-calcium grade. Limestone, probably of Paleozoic age and of medium to course (sic) grain and blue-gray to white hues, exist in the relatively inaccessible interior of the Klamath Mountains, notably in the subrange known as the Marble Mountains. Among the four formations, the McCloud Limestone probably contains the largest resources, but in the most accessible parts both magnesia and silica tend to be widely and sporadically distributed. The Hosselkus Limestone contains more uniform rock. Limestone has been quarried from the McCloud Limestone, near Redding, from the Kennett Formation on Backbone Creek (a tributary to the McCloud River), from the Hosselkus Limestone near Ingot, and from the Gazelle Formation near Gazelle.

"Several deposits of Hosselkus Limestone of potential economic importance are in and adjacent to the Genessee Valley of Plumas County, near the Western Pacific Railroad. They have not yet received much attention because of the availability of more accessible materials. The same is true of several deposits on the Feather and Yuba Rivers of the northern Sierra Nevada.

"In the west-central Sierra Nevada, most industrial limestone and dolomite deposits are in discontinuous series of simple lenticular masses in other metamorphic rocks or as pendants in granitic rock. Less commonly, they occur in masses having complicated outlines because of severe folding. A few of the limestone deposits have yielded fossils ranging, at various localities, from Mississippian to Permian, but fossil evidence is very sparsely distributed. A few small bodies occur in Jurassic rocks. The principal districts in the west-central belt that are producing commercial limestone or dolomite are the Cool-Cave Valley and Diamond Springs-Shingle Springs areas of El Dorado County; the Volcano district of Amador County; the San Andreas district of Calaveras County; and the Standard-Sonora-Columbia district of Tuolumne and Calaveras Counties.

"The crystalline limestones of the west-central Sierran foothill belt are associated with slate, metachert, phyllite, mica schist and greenstone of the upper Paleozoic Calaveras formation. The largest masses occur east of the Mother Lode belt, but these are medium to coarse grained and commonly are mixtures of limestone and dolomite so that careful sampling and selective mining is often necessary. Rock colors most commonly are blue-gray or white or variations of these. Dolomite generally is white to off-white. A succession of relatively small lenses (most not over a quarter of a mile long by 300 feet or less thick) containing predominantly fine-grained, dense dove-gray to blue-gray limestone is found in a narrow belt in the foothill area west of the Mother Lode, from Placer County south to western Calaveras County. On the whole, these lenses have been less intensely metamophosed than deposits east of the Mother Lode, and limestone from them holds its lump form much better during calcination. However, only a few are large enough and of sufficient high purity to be either active or potential sources of industrial limestone.."

"Very few reasonably accessible limestone deposits exist in the northern Coast Ranges, and the market is limited because of the small population. In the central Coast Ranges, large roof-pendants of crystalline limestone and dolomite are found in the Santa Cruz, Gabilan and Santa Lucia Mountains and in the Sierra de Salinas. Carbonate rocks of these complexes, of probable Paleozoic age, commonly are coarse grained, and white and blue-gray colors predominate. Both high-grade limestones and high-grade dolomite occur in deposits large enough for major exploitation (masses aggregating tens to hundreds of millions of tons); deposits of the northern Gabilan range and southern Santa Cruz Range supply much of the current demand in the San Francisco Bay area. Nearly all of the dolomite currently used in northern California is quarried from deposits in the northern Gabilan Range. Dense, fine-grained limestones found in the Franciscan Formation of Jurassic and Cretaceous age also supply notable tonnages to San Francisco Bay industries, particularly to the cement plant at Permanente, Santa Clara County. Quaternary oyster shells dredged from San Francisco Bay supply one cement plant at Redwood City, San Mateo County. (circa 1966)

"The immense resources of coarse-grained, white crystalline limestone of the Pico Blanco district constitute virtually the only undeveloped major deposits of high-grade limestone close to tidewater anywhere on the California, Oregon, and Washington coasts. they are close to State Highway 1, 25 miles southeast of Monterey and only 3 airline miles from the Pacific Ocean. Lack of close railroad facilities and access roads has hindered their development so far. Tertiary unmetamorphosed limestones of considerable present economic importance, and even greater future significance as the population increases, are sparsely distributed in the southern Coast Ranges of San Luis Obispo, Santa Barbara and Ventura Counties. Beds of shell limestone in the Oligocene (?) and lower Miocene Vaqueros Formation are quarried at Lime Mountain west of San Miguel for use in sugar refineries of Salinas Valley. Deposits of algal limestone in the Eocene Sierra Blanca Formation can supply good quality, dense limestone to industries in Santa Barbara and Ventura Counties should the demand arise.

"Extensive deposits of carbonate rocks in the Tehachapi Mountains between Mojave and Grazier Mountain support two cement plants, one at Mojave and one at Monolith. Other industries to be based on these deposits are in the planning stages. The carbonate rocks occur as pendants more or less encased in granitic rocks, either alone or interbedded with mica schist and quartzite in sequences referred to either the Bean Canyon Formation or the Kernville Series. These rock groups are probably of late Paleozoic and/or early Mesozoic age, although fossils have not been found in them. The rocks are commonly coarse grained and colors range from white to blue-gray. Masses of dense, fine-grained rock are unknown in this area. Limestone, dolomite, and magnesian limestones are all present within the district. Some very pure, very white, very coarse-grained limestones exist west of Cantil at the headwaters of the Back Canyon drainage. Potentially exploitable deposits of both limestone and dolomite occur in Neenach quadrangle east of Lebec, and large deposits of cement-grade rock are distributed through the district. Granitic intrusions are common within many of the limestone bodies, and silica and silicate minerals introduced by contact metamorphism are also a common problem in the district.

"The chemical plants located at Searles Lake, Inyo County, together with the rail facilities that serve them, create a favorable economic environment that allows the extensive limestone deposits (Carboniferous?) of the Argus Range to be exploited. Carbonate rock deposits across Panamint Valley in the Panamint Range may ultimately be brought into production. Both high-grade dolomite and limestone are found there. Light-gray colors prevail, and both limestones and dolomites are medium to fine grained.

"Extensive deposits of fine-grained white dolomite are being mined underground near Keeler in the Owens Valley of Inyo County for use as terrazzo chips and white aggregate for the Los Angeles marketing complex. Immense reserves of dolomite exist there, and limestone deposits can be developed farther to the east. The dolomite is in the Ely Springs and Hidden Valley Dolomites of Ordovician to Devonian age, whereas the best limestones in the Lost Burro Formation of Middle and Late Devonian age.."

Commercial use of material within this site is strictly prohibited. It is not to be captured, reworked, and placed inside another web site ©. All rights reserved. Peggy B. and George (Pat) Perazzo.